Wide Belt Sanding Machine – RRP 1300 Wide Belt Metal Sanding Machine

Designed for large-scale production, this advanced machine ensures smooth, flawless results with minimal effort. Whether for deburring, polishing, or smoothing metal surfaces, the Wide Belt Sanding Machine offers exceptional performance, durability, and efficiency. In this article, we will explore the key features, benefits, and applications of the RRP 1300 wide belt sanding machine, which makes it a top choice for various industrial sectors.

Table of Contents

Why Choose the Wide Belt Sanding Machine RRP 1300?

The Wide Belt Sanding Machine RRP 1300 stands out for its impressive capabilities in handling metal sheets, ensuring a uniform finish across large surfaces. Its innovative design and user-friendly features make it a go-to solution for industrial sanding tasks.

- High-Surface Coverage: The RRP 1300 offers an ample 1300 mm sanding width, allowing you to process larger workpieces efficiently.

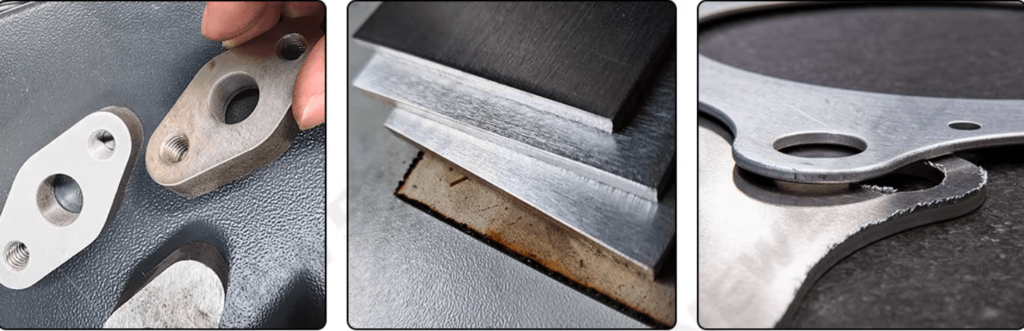

- Precise Sanding and Polishing: With advanced abrasive belt technology, the machine guarantees smooth and even finishes, removing imperfections such as burrs and scratches.

- Industrial Durability: Constructed from high-quality materials, the Wide Belt Sanding Machine is built to last, even in heavy-duty production environments.

- Versatile Applications: Capable of handling a variety of metal types, including stainless steel, aluminum, brass, and more, for a wide range of industries.

Key Features of the Wide Belt Sanding Machine

The Wide Belt Sanding Machine is engineered with several high-performance features designed to enhance efficiency and improve finish quality. Here are the standout features of the RRP 1300 model:

- Advanced Abrasive Belt System: Offers superior sanding performance for smooth and consistent surface treatment.

- Variable Speed Control: Allows operators to adjust the sanding speed based on material type and finish requirements, optimizing productivity.

- Heavy-Duty Motor: Powered by a high-performance motor, the machine ensures constant power output even during prolonged operation.

- User-Friendly Controls: Simple-to-operate control panel enables easy adjustments for quick setup and operation, reducing downtime.

Benefits of Using the RRP 1300 Wide Belt Sanding Machine

The Wide Belt Sanding Machine RRP 1300 provides numerous benefits, making it an excellent investment for businesses in need of high-quality metal finishes.

- Increased Productivity: The machine’s wide belt and high-speed capabilities help reduce sanding time, enabling faster production cycles.

- Consistent Results: The precision sanding action ensures that every piece receives a uniform finish, which is essential for high-quality metal products.

- Reduced Operational Costs: With long-lasting abrasive belts and minimal maintenance requirements, the RRP 1300 provides a cost-effective solution for long-term operations.

- Enhanced Flexibility: Suitable for a wide range of sanding applications, from fine polishing to heavy deburring and surface finishing.

Applications of the RRP 1300 Wide Belt Sanding Machine

The Wide Belt Sanding Machine RRP 1300 is designed for a variety of applications across several industries. Its ability to handle large workpieces and perform high-precision sanding makes it an ideal choice for the following uses:

- Metal Fabrication: Perfect for deburring, polishing, and finishing metal sheets used in the manufacturing of structural components.

- Automotive Industry: Ideal for sanding metal parts, ensuring smooth finishes and removing imperfections from automotive components.

- Construction and Heavy Machinery: Used for preparing large metal sheets for coating or further processing in construction and machinery sectors.

- Furniture Manufacturing: Ideal for sanding metal components used in furniture production, ensuring a high-quality surface ready for finishing.

How to Maintain Your Wide Belt Sanding Machine

Proper maintenance is key to prolonging the life of your Wide Belt Sanding Machine RRP 1300 and ensuring its peak performance. Regular care helps prevent issues such as uneven sanding or excessive wear on the abrasive belts.

- Regular Belt Inspections: Inspect the abrasive belts frequently for signs of wear or damage. Replace belts as needed to maintain optimal sanding quality.

- Clean the Machine Regularly: Remove dust and debris from the machine after each use to ensure smooth operation and reduce wear on components.

- Lubricate Moving Parts: Periodically lubricate the machine’s moving parts to ensure they function smoothly and prevent overheating.

- Check Calibration: Regularly check the machine’s calibration to ensure that the sanding width and belt tension are set correctly.

Conclusion

The Wide Belt Sanding Machine RRP 1300 is a high-performance, durable, and versatile tool that excels in providing smooth and precise surface finishes for metal sheets. Its advanced abrasive belt technology, user-friendly controls, and robust construction make it a valuable asset for industries such as metal fabrication, automotive, furniture manufacturing, and more.

Investing in the Wide Belt Sanding Machine ensures enhanced productivity, superior finish quality, and a cost-effective solution for long-term industrial sanding needs. If you’re looking for a reliable and efficient sanding machine, the RRP 1300 Wide Belt Sanding Machine is the perfect choice for all your metal sanding applications.

The Wide Belt Sanding Machine RRP 1300 is a high-performance, durable, and versatile tool that excels in providing smooth and precise surface finishes for metal sheets. Its advanced abrasive belt technology, user-friendly controls, and robust construction make it a valuable asset for industries such as metal fabrication, automotive, furniture manufacturing, and more.

Investing in the Wide Belt Sanding Machine ensures enhanced productivity, superior finish quality, and a cost-effective solution for long-term industrial sanding needs. If you’re looking for a reliable and efficient sanding machine, the RRP 1300 Wide Belt Sanding Machine is the perfect choice for all your metal sanding applications.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao