Why Wet Metal Sanders Are Best for Plasma Dross Removal

While many tools and methods are available, a wet metal sander stands out as the most effective solution for achieving smooth, professional results.

Table of Contents

The Challenge of Plasma Dross Removal

Plasma dross is tough, sharp, and irregular, making it difficult to remove with traditional tools. Common approaches like manual chisels, flap discs, and even standard wide belt sanders often fall short for several reasons:

- Hardness of Dross: The hardened metal edges can quickly damage belts or discs.

- Dust and Heat: Sanding dry produces excessive heat and dust, which can compromise both worker safety and the finish quality.

- Inconsistent Results: Manual methods can be labor-intensive and lead to uneven edges.

This is where a wet metal sander excels, offering precision, durability, and efficiency that traditional methods can’t match.

What Makes Wet Metal Sanders Ideal?

Superior Dross Removal

Wet metal sanders are designed to handle the hardest materials, including plasma dross. The addition of water or coolant minimizes friction and heat, protecting the abrasive surface from premature wear and delivering consistent results.

Reduced Dust and Safer Workspace

Plasma dross removal with dry methods creates significant dust, which can be hazardous. Wet sanding eliminates airborne particles, creating a cleaner and safer work environment.

Enhanced Belt Longevity

The cooling effect of water prevents belts from overheating and reduces the risk of tearing, allowing for longer use and lower replacement costs.

High-Quality Finishes

Wet sanding ensures smoother, more polished edges. It removes dross while preparing the surface for further processing, such as painting, coating, or welding.

Ideal for High-Volume Operations

For workshops or production facilities handling a high volume of plasma-cut materials, wet metal sanders provide a time-saving, professional-grade solution.

Why Not Use a Standard Wide Belt Sander?

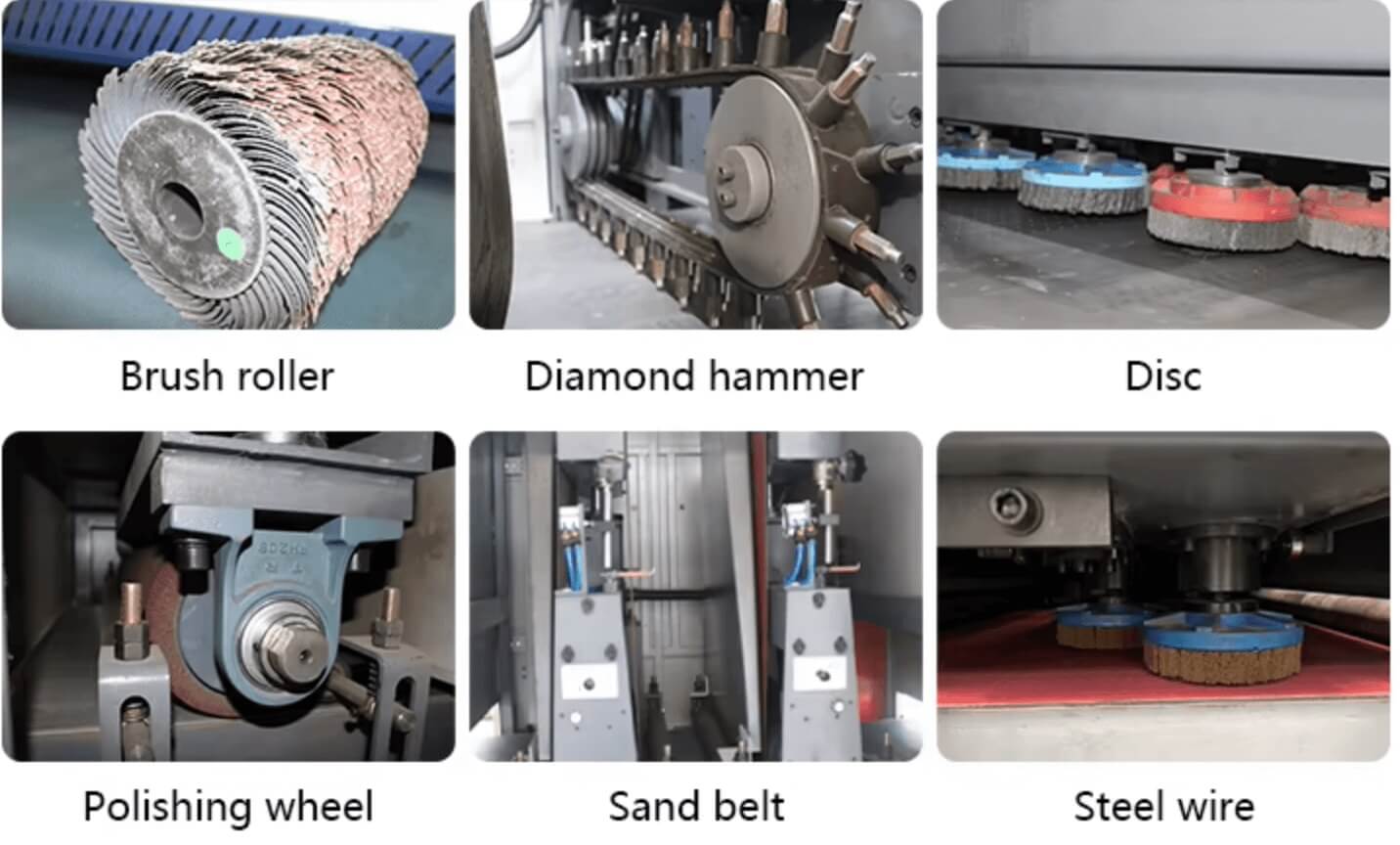

Standard wide belt sanders are not designed to handle the challenges of plasma dross. Without rotary brushes or wet sanding capabilities, these machines:

- Tear belts quickly due to the sharp dross nibs.

- Struggle to produce consistent results.

- Create excessive dust, which can affect the working environment and machine longevity.

High-end commercial machines that combine rotary brushes and wet sanding are better suited for handling plasma dross.

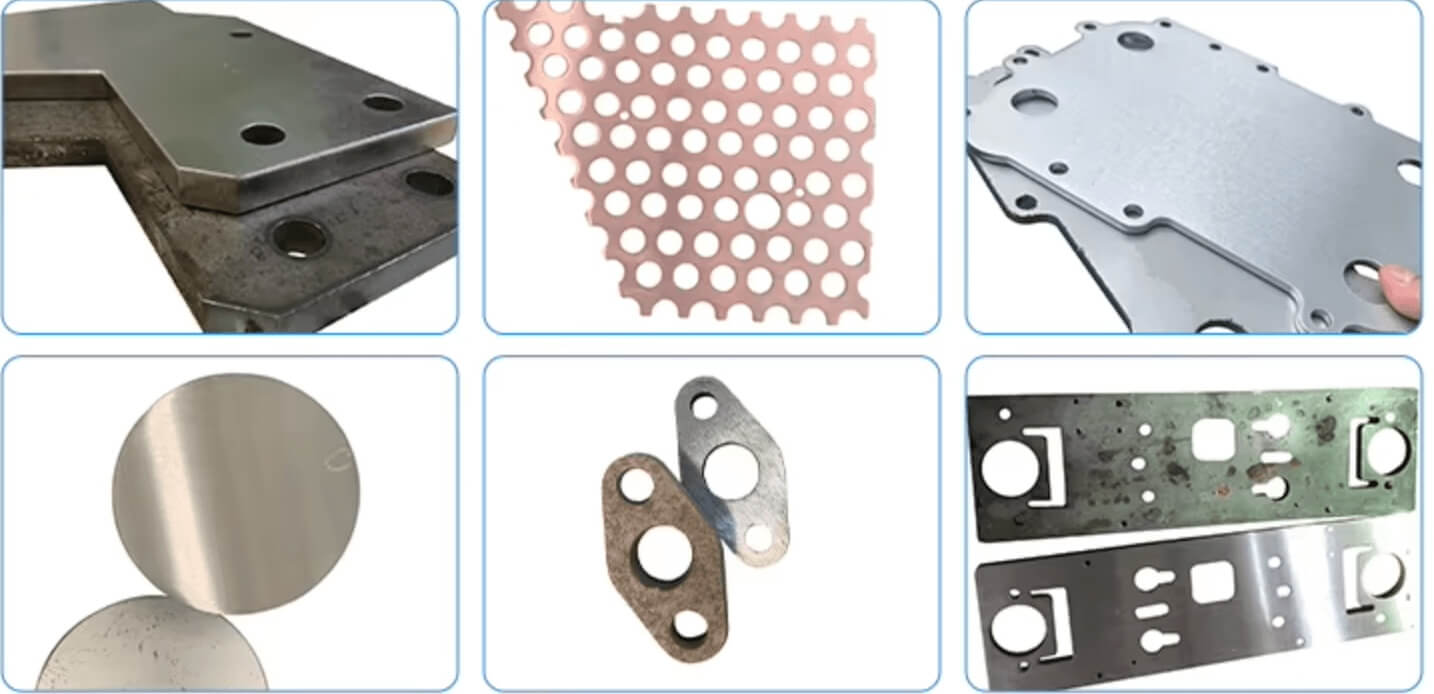

Recommended Applications for Wet Metal Sanders

- Plasma-Cut Stainless Steel: Achieve clean, burr-free edges ideal for welding or painting.

- Iron and Aluminum Edges: Smooth out rough plasma-cut edges with precision.

- High-Volume Metal Fabrication: Increase efficiency and reduce manual labor in large-scale operations.

Conclusion: Invest in a Wet Metal Sander for Plasma Dross

When it comes to removing plasma dross, a wet metal sander is the ultimate solution. It combines the durability and power needed for tough edges with the precision and cleanliness required for professional finishes. By reducing dust, prolonging belt life, and improving efficiency, wet metal sanders save time, money, and effort in both small-scale and large-scale operations.

If you’re looking to elevate your plasma-cutting process and achieve flawless results, consider investing in a high-quality wet metal sander.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao