Why Metal Sanding Machines Are Essential for Perfect Finishes

Compared to manual sanding, metal sanding machines provide unmatched efficiency, precision, and consistency, making them the superior choice for modern metalworking tasks.

Table of Contents

Why Choose a Metal Sanding Machine Over Manual Sanding?

High Efficiency

Manual sanding can be time-consuming and physically demanding, while metal sanding machines dramatically reduce the time required for surface preparation. Whether working on large metal sheets or intricate components, these machines deliver results quickly and effectively.Consistent Surface Quality

Manual sanding often results in uneven surfaces due to varying pressure or human error. Metal sanding machines ensure consistent and uniform sanding results, producing flawless finishes that are free from imperfections and scratches.Versatility for Different Metals

Metal sanding machines are designed to handle a wide variety of materials, including stainless steel, aluminum, brass, and iron. With adjustable speed and pressure settings, they can meet the specific requirements of different metals and finishes.Enhanced Quality and Durability

These machines are equipped with advanced abrasive technology to remove imperfections, smooth weld seams, and improve paint adhesion. This ensures the metal surface is well-prepared for durable coatings and reduces the risk of corrosion or wear.Specialized Design for Diverse Applications

Unlike hand tools, metal sanding machines come in specialized designs to meet various needs. For example, wide belt sanders are ideal for large-scale metal sheets, while edge sanders are perfect for detailed work. This versatility makes them indispensable for professionals.

Applications of Metal Sanding Machines

- Automotive Manufacturing and Restoration: Preparing car bodies for painting or repair work.

- Metal Fabrication and Welding: Smoothing weld seams and preparing components for assembly.

- Furniture and Decorative Metalwork: Creating polished, high-quality finishes for furniture and decorative items.

- Industrial Production: Providing consistent surface treatments for large-scale manufacturing.

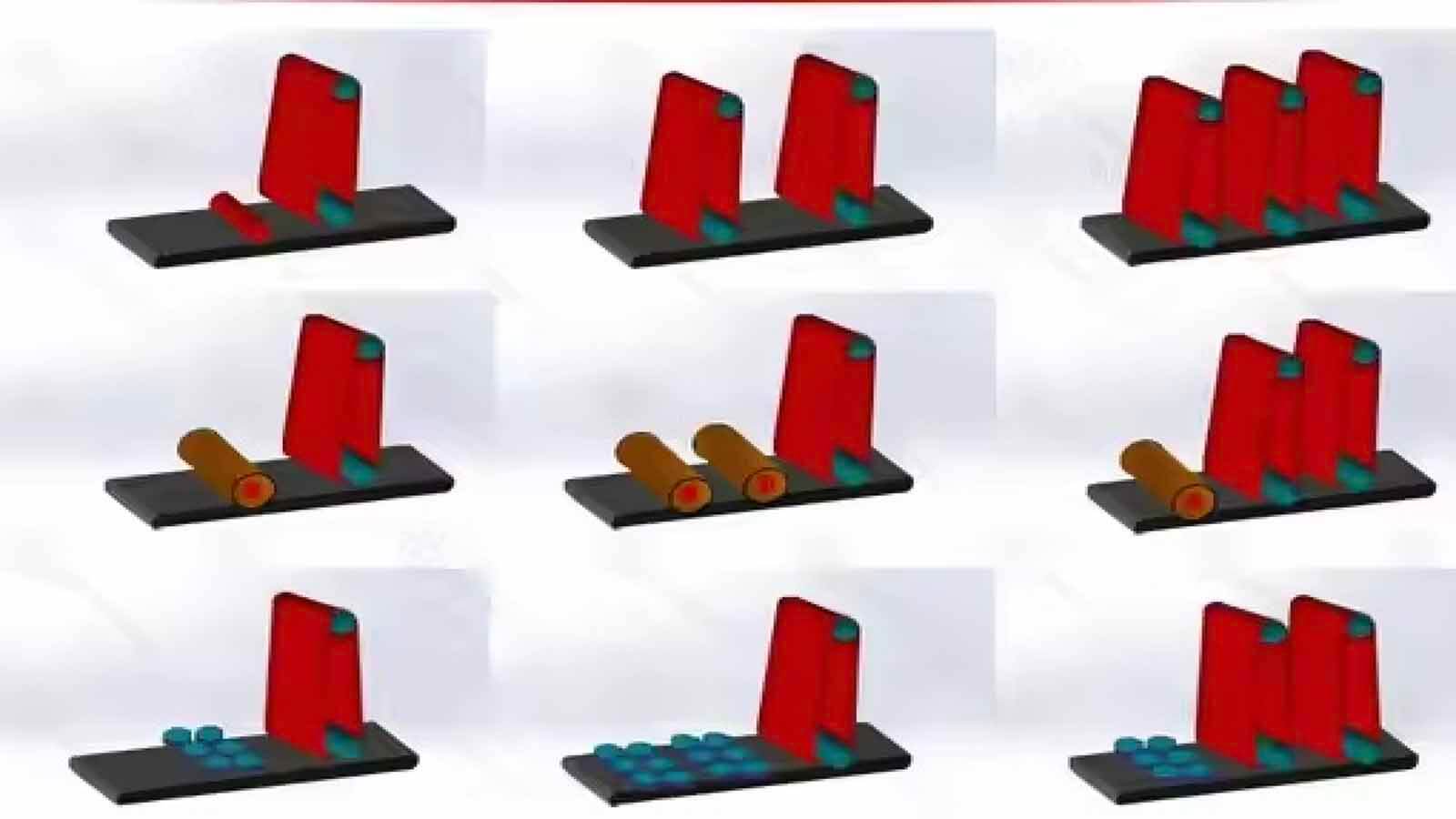

Types of Sanding Machines

Conclusion

Switching to metal sanding machines from manual sanding is not just an upgrade—it’s a transformation. These machines bring precision, efficiency, and reliability to your metalworking processes, ensuring you deliver superior results in less time. In today’s competitive market, investing in a metal sanding machine is a step toward higher productivity and excellence.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao