What is the Metal Rolling Brush Deburring Machine?

The metal rolling brush deburring machine is a key solution for removing burrs, sharp edges, and surface imperfections efficiently. This machine is widely used in industrial workshops, metalworking factories, and production lines where speed, consistency, and durability matter.

Table of Contents

What Is a Metal Rolling Brush Deburring Machine?

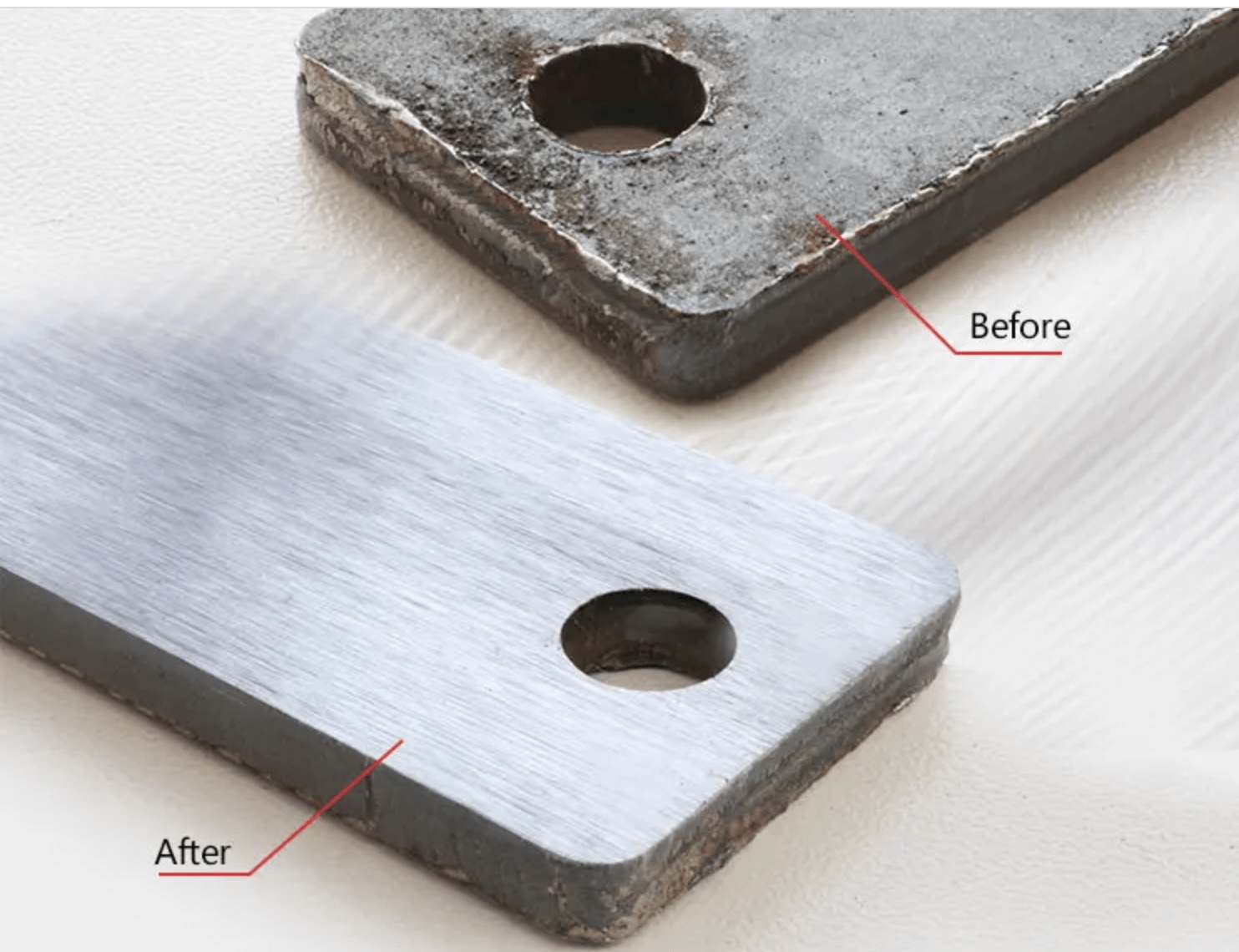

A metal rolling brush deburring machine is an industrial device designed to clean, polish, and deburr metal surfaces. It uses rotating brushes to remove rough edges and burrs from sheet metal, rods, or profiles. Unlike manual sanding or grinding, this machine ensures uniform results across large volumes of parts.

Key Features:

- Rotating Brush System: Smooths edges and surfaces efficiently

- Adjustable Speed: Can handle different materials and thicknesses

- Durable Construction: Suitable for continuous, heavy-duty use

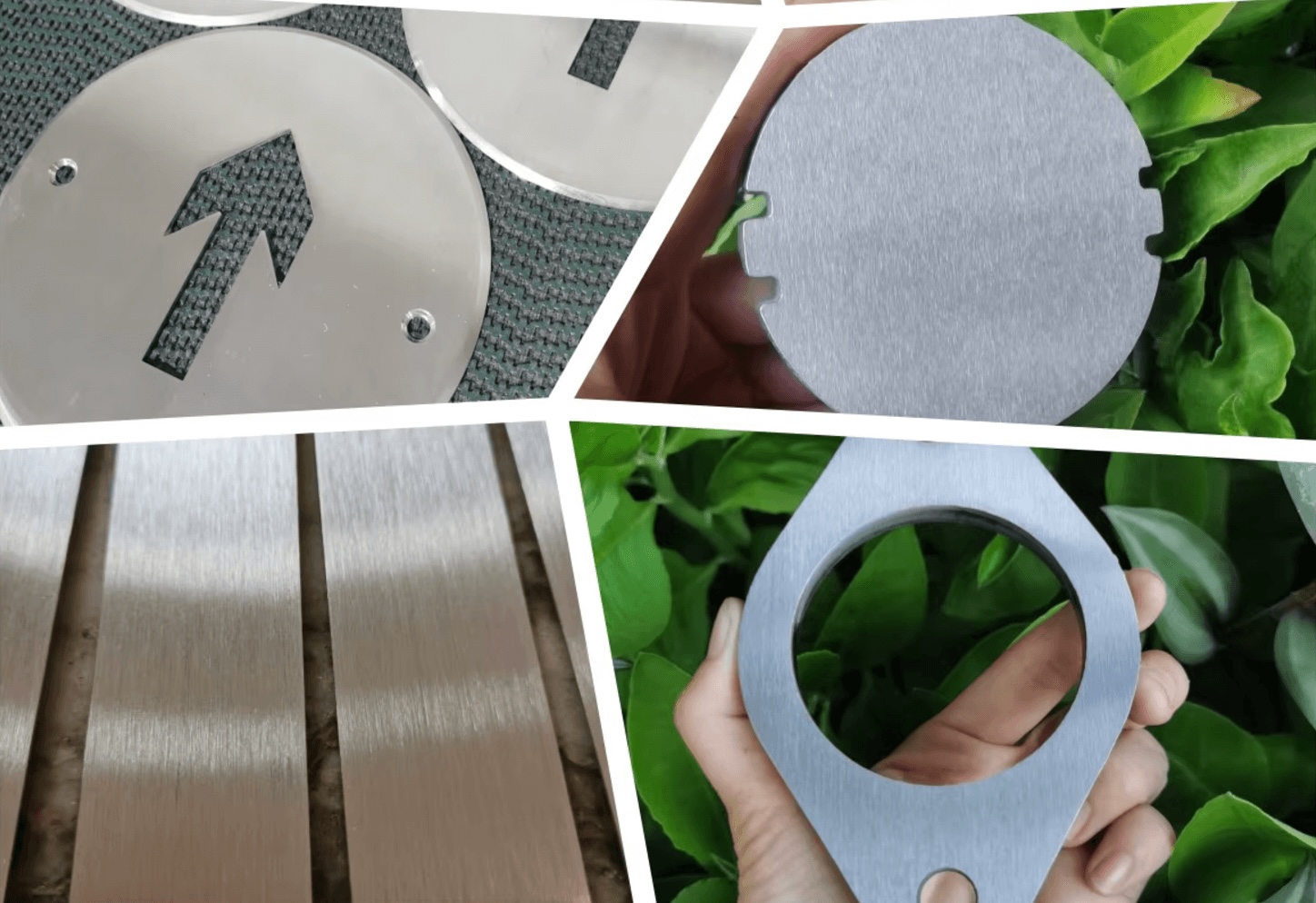

- Versatile Application: Works on stainless steel, aluminum, brass, and other metals

How Does It Work?

The machine operates by passing metal parts under or through a series of high-speed rotating brushes. These brushes are made of abrasive or nylon bristles, which remove burrs without damaging the main surface.

Steps:

- Load the metal sheets, rods, or components onto the conveyor.

- Adjust brush speed and pressure based on material and thickness.

- Activate the machine—rotating brushes polish and deburr in one pass.

- Unload the finished parts, which now have smooth, burr-free edges.

Benefits of Using a Metal Rolling Brush Deburring Machine

- Improved Safety: Eliminates sharp edges that can cause injuries.

- Higher Efficiency: Processes large volumes of parts faster than manual methods.

- Consistent Finish: Ensures uniform deburring and polishing across all parts.

- Material Flexibility: Works with stainless steel, aluminum, brass, and more.

- Reduced Labor Costs: Minimizes manual effort while increasing output.

Applications

- Sheet Metal Fabrication: Removes burrs after laser cutting, punching, or shearing.

- Automotive Industry: Polishes metal components before assembly or coating.

- Furniture Manufacturing: Smooths metal frames and decorative parts.

- Metal Parts Production: Prepares components for further machining or finishing.

Conclusion

A metal rolling brush deburring machine is an essential investment for modern metalworking. It improves efficiency, ensures safety, and delivers high-quality, burr-free finishes for a variety of industrial applications.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao