What Is the Metal Rolling Brush Deburring Machine?

Among various finishing tools, the metal rolling brush deburring machine stands out as an efficient and versatile solution. This machine uses rolling abrasive brushes to clean, polish, and smooth metal surfaces and edges, making it a favorite in many industrial applications.

Table of Contents

What Is a Metal Rolling Brush Deburring Machine?

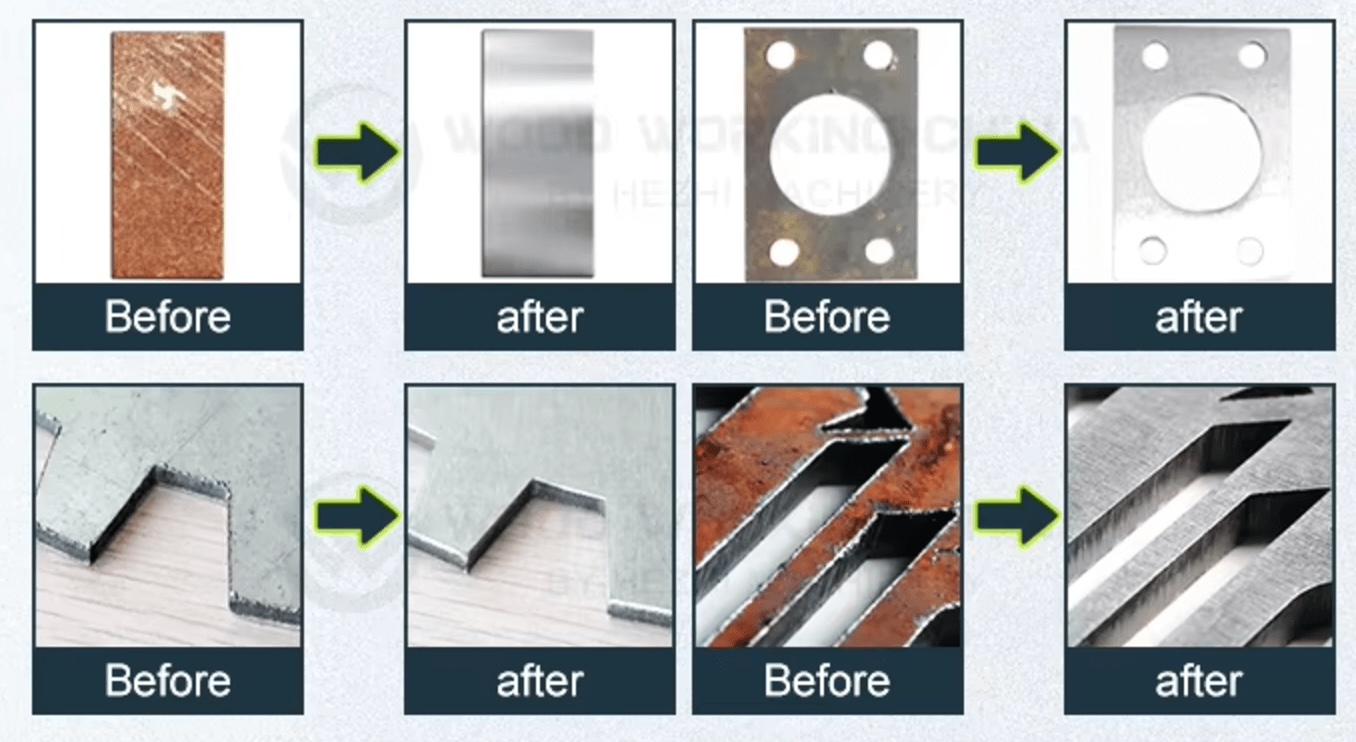

A metal rolling brush deburring machine is a type of finishing equipment that employs rotating brush wheels embedded with abrasive materials to remove burrs, rust, scale, and surface contaminants from metal parts. The brushes roll over the surface and edges of the workpiece, effectively smoothing rough areas and improving the overall finish.

Unlike other deburring methods that rely on belts or grinding wheels, rolling brushes provide a gentler and more uniform action. This makes them ideal for delicate parts or surfaces that require a consistent finish without damaging the base metal.

How Does It Work?

The machine operates by feeding metal parts through a series of rotating brushes. These brushes spin on axes perpendicular or parallel to the metal surface, depending on the machine design and application needs. As the parts pass through, the abrasive brushes “roll” over edges and surfaces, scraping away burrs and polishing the metal.

Many rolling brush deburring machines feature adjustable brush speed, pressure, and angles to accommodate different metal types, thicknesses, and burr sizes. This flexibility allows operators to fine-tune the process for optimal results.

Key Features of Metal Rolling Brush Deburring Machines

- Rotating Abrasive Brushes: Equipped with nylon or wire brushes embedded with abrasives such as silicon carbide or aluminum oxide for efficient burr removal.

- Adjustable Speed and Pressure: Operators can control brush rotation speed and contact pressure to suit various metals and surface conditions.

- Conveyor Feeding: Automated feeding systems ensure consistent throughput and uniform deburring.

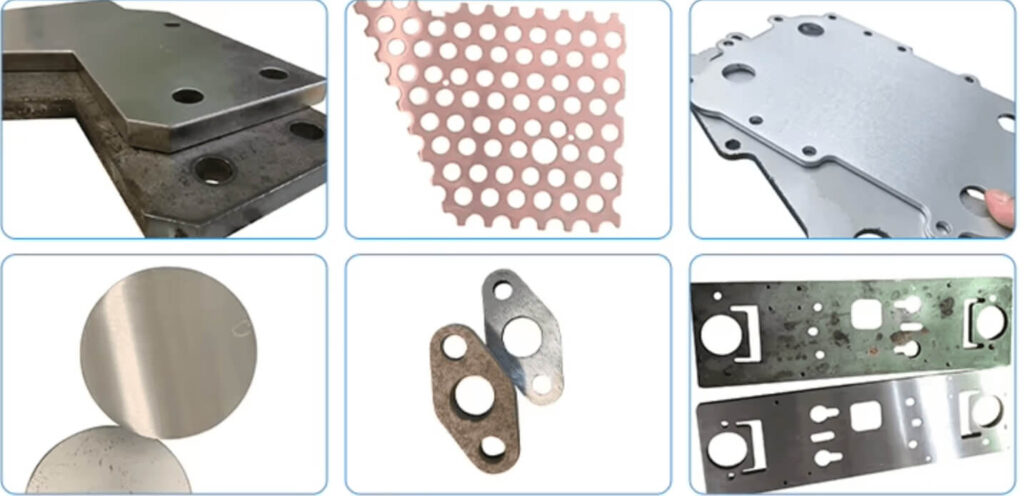

- Versatility: Suitable for steel, stainless steel, aluminum, brass, and other metals.

- Compact Footprint: Many models are designed for easy integration into production lines without taking up excessive space.

Metal Sander Machine Specification Table

| Model | MS-1000 / MS-1300 / MS-1600 (customizable) |

|---|---|

| Working Width | 1000mm / 1300mm / 1600mm |

| Max. Workpiece Thickness | 0.5mm – 100mm |

| Minimum Workpiece Size | 50mm x 50mm |

| Abrasive Belt Size | 1900mm x 1030mm (can be customized) |

| Brush Head Type | Rotary + Oscillating |

| Deburring Method | Wide Belt Sanding + Edge Rounding Brushes |

| Processing Speed | 0.5 – 8 m/min (adjustable) |

| Brush Diameter | 150mm – 200mm (depending on model) |

| Conveyor Type | Vacuum / Magnetic Table (optional) |

| Control System | PLC Touch Screen (Siemens/Delta) |

| Dust Collection Port | 4 x Ø 125mm |

| Power Supply | 380V, 50Hz, 3 Phase (custom voltage optional) |

| Main Motor Power | 15kW – 30kW (based on configuration) |

| Brush Motor Power | 3kW – 7.5kW (per head) |

| Total Power | 20kW – 45kW (depends on model) |

| Machine Dimensions (L×W×H) | Approx. 2800mm x 1800mm x 2200mm |

| Machine Weight | Approx. 2500kg – 4000kg |

| Applications | Deburring, Edge Rounding, Surface Polishing of flat sheet metal (SS, CS, Aluminum) |

| Optional Features | Water Spray for Cooling, Automatic Thickness Detection, Dust Collector |

Benefits of Using a Metal Rolling Brush Deburring Machine

- Improved Surface Quality: Produces smooth, burr-free surfaces ready for subsequent processes such as painting or assembly.

- Increased Productivity: Automates a labor-intensive process, reducing manual work and speeding up production.

- Enhanced Safety: Removes sharp edges, minimizing workplace injury risks.

- Cost-Effective: Durable brushes and low maintenance costs make it an economical choice.

- Environmentally Friendly: Unlike chemical deburring, it uses mechanical abrasion without harmful substances.

Improved Surface Quality: Produces smooth, burr-free surfaces ready for subsequent processes such as painting or assembly.

Increased Productivity: Automates a labor-intensive process, reducing manual work and speeding up production.

Enhanced Safety: Removes sharp edges, minimizing workplace injury risks.

Cost-Effective: Durable brushes and low maintenance costs make it an economical choice.

Environmentally Friendly: Unlike chemical deburring, it uses mechanical abrasion without harmful substances.

Common Applications

- Deburring and polishing flat metal sheets, tubes, and profiles

- Surface preparation before coating or painting

- Cleaning rust and scale from metal surfaces

- Edge rounding and finishing in automotive, aerospace, and appliance manufacturing

Conclusion

The metal rolling brush deburring machine is an essential tool for metal fabricators seeking efficient, safe, and high-quality deburring solutions. Its unique rolling brush mechanism offers gentle yet effective burr removal and polishing, suitable for a wide range of metals and industries. Investing in this machine can significantly improve product finish, increase throughput, and enhance workplace safety.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao