What is Metal Sanders Machine

By utilizing abrasive belts, polishing wheels, and specialized tools, these machines achieve precision sanding, polishing, and edge finishing, ensuring a high-quality surface for diverse applications. Metal sanders are essential in various industries, improving productivity, aesthetics, and product functionality.

Table of Contents

Features of a Metal Sanders Machine

- Versatile Sanding Options: Equipped with multiple sanding belts to handle tasks from rough surface removal to fine finishing.

- Integrated Polishing and Deburring: Combines sanding, polishing, and deburring in one machine for streamlined processing.

- Customizable Configurations: Machines can be tailored to different operations, such as multi-stage sanding, adjustable pressure settings, and interchangeable tools.

- High Efficiency: Designed for continuous operation, reducing manual labor and increasing production speed.

- Precision Engineering: Features adjustable speeds and angles for precise surface treatments and edge detailing.

- Material Flexibility: Compatible with a wide range of metals, including stainless steel, aluminum, carbon steel, and more.

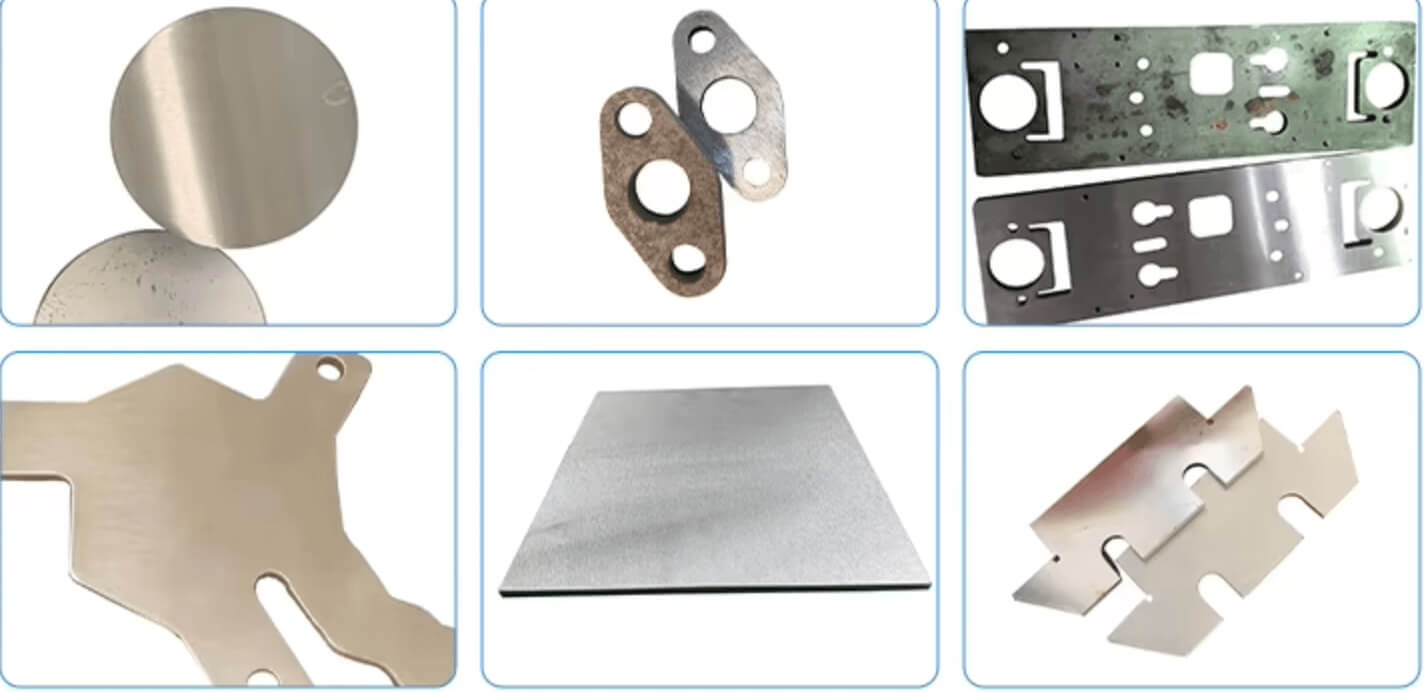

Applications of Metal Sanders Machines

- Surface Finishing: Achieving smooth, uniform surfaces for decorative or functional purposes.

- Deburring: Removing sharp edges, burrs, and welding marks for enhanced safety and aesthetics.

- Polishing: Creating high-gloss finishes or specialized textures, such as brushed or satin effects.

- Edge Finishing: Rounding or beveling edges for safety and a professional look.

Industries Using Metal Sanders Machines

Metal sanders are indispensable across industries that demand precision and high-quality finishes, including:

Automotive: Preparing parts like panels, frames, and exhaust components.

Construction: Smoothing metal sheets and beams for architectural projects.

Appliances: Finishing stainless steel components for refrigerators, ovens, and kitchenware.

Metalworking: General surface preparation and polishing for diverse metal products.

Elevators and Escalators: Producing polished panels with brushed textures.

Materials Compatible with Metal Sanders Machines

Metal sanders are designed to work with a variety of metals, including:

Stainless Steel: Ideal for creating brushed finishes and mirror-like surfaces.

Aluminum: Smooths and polishes lightweight metals used in construction and transportation.

Carbon Steel: Removes imperfections and prepares for coating or assembly.

Copper and Brass: Enhances decorative and functional elements.

Titanium: Prepares high-strength materials for aerospace and medical applications.

Why Choose a Metal Sanders Machine?

Investing in a metal sanders machine improves product quality, reduces labor intensity, and ensures consistent results. The ability to customize machines based on your industry, materials, and application needs makes them an essential tool for modern manufacturing.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao