What Is a Sheet Metal Edge Deburring Machine?

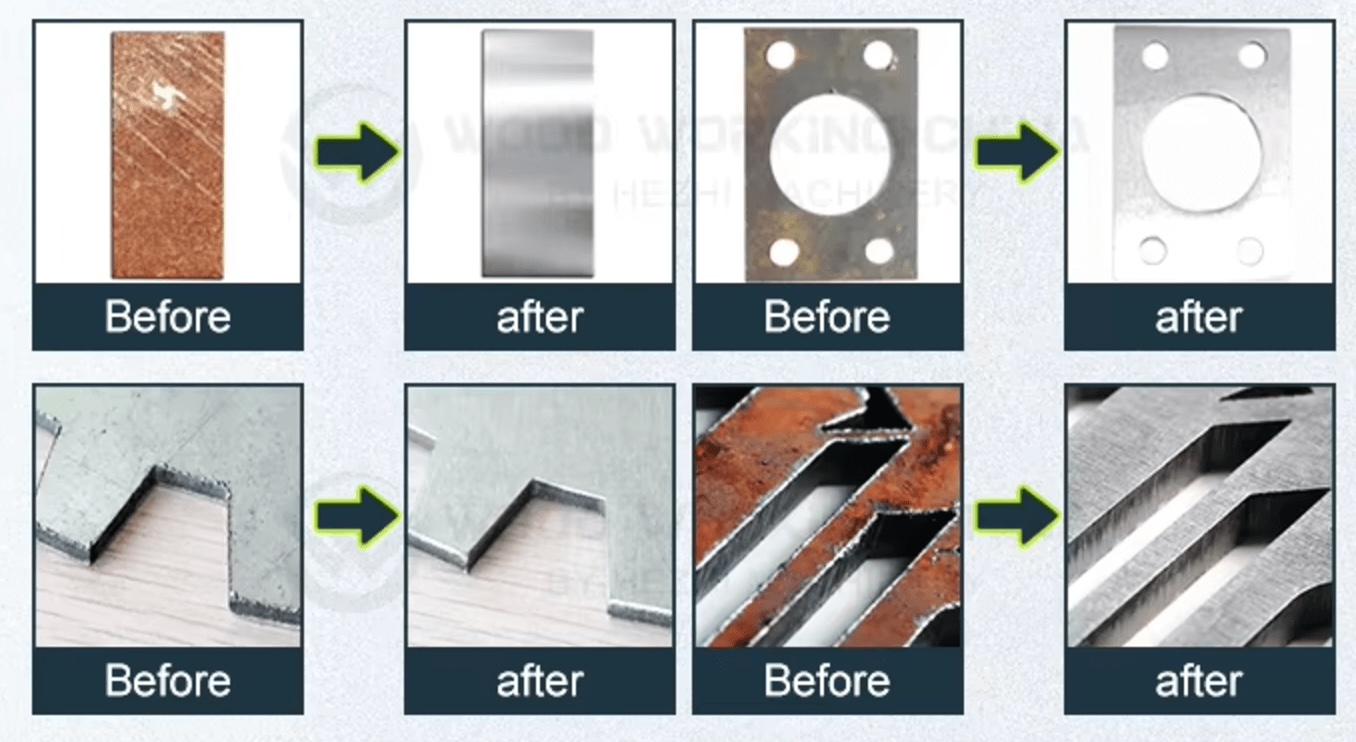

After cutting or stamping, sheet metal often has sharp edges and burrs that can cause injury, interfere with assembly, or affect the product’s performance. Manually removing these imperfections can be time-consuming and inconsistent. That’s why many manufacturers rely on a sheet metal edge deburring machine—a specialized solution designed to quickly and efficiently smooth and finish metal edges, ensuring higher quality and safer handling.

Table of Contents

What Is a Sheet Metal Edge Deburring Machine?

In the metal fabrication industry, the finishing process is just as important as the initial cutting and shaping of metal parts. One key step in finishing sheet metal components is deburring — the removal of unwanted sharp edges, burrs, and rough surfaces left behind after cutting, stamping, or machining. This is where a sheet metal edge deburring machine comes into play.

Understanding Sheet Metal Edge Deburring Machines

A sheet metal edge deburring machine is a specialized piece of equipment designed to efficiently remove burrs and sharp edges from flat metal sheets and components. Burrs are small, often jagged projections of metal that can form during various manufacturing processes. They not only affect the aesthetic quality of the product but can also pose safety hazards to workers handling the parts.

The machine works by using abrasive belts, brushes, or wheels to grind down and smooth the edges of sheet metal pieces. This automated process is much faster, more consistent, and safer compared to manual deburring methods like hand filing or sanding.

Key Features of Sheet Metal Edge Deburring Machines

- High Precision: These machines provide uniform edge finishing, ensuring every part meets quality standards.

- Adjustable Settings: Operators can control speed, pressure, and abrasive type to match different metal thicknesses and materials.

- Versatile Applications: Suitable for steel, aluminum, stainless steel, copper, and other metals commonly used in fabrication.

- Automation: Many models include conveyors and automatic feeding systems for continuous processing, boosting productivity.

- Safety Improvements: Reducing manual handling of sharp edges minimizes the risk of injuries in the workshop.

Metal Sander Machine Specification Table

| Model | MS-1000 / MS-1300 / MS-1600 (customizable) |

|---|---|

| Working Width | 1000mm / 1300mm / 1600mm |

| Max. Workpiece Thickness | 0.5mm – 100mm |

| Minimum Workpiece Size | 50mm x 50mm |

| Abrasive Belt Size | 1900mm x 1030mm (can be customized) |

| Brush Head Type | Rotary + Oscillating |

| Deburring Method | Wide Belt Sanding + Edge Rounding Brushes |

| Processing Speed | 0.5 – 8 m/min (adjustable) |

| Brush Diameter | 150mm – 200mm (depending on model) |

| Conveyor Type | Vacuum / Magnetic Table (optional) |

| Control System | PLC Touch Screen (Siemens/Delta) |

| Dust Collection Port | 4 x Ø 125mm |

| Power Supply | 380V, 50Hz, 3 Phase (custom voltage optional) |

| Main Motor Power | 15kW – 30kW (based on configuration) |

| Brush Motor Power | 3kW – 7.5kW (per head) |

| Total Power | 20kW – 45kW (depends on model) |

| Machine Dimensions (L×W×H) | Approx. 2800mm x 1800mm x 2200mm |

| Machine Weight | Approx. 2500kg – 4000kg |

| Applications | Deburring, Edge Rounding, Surface Polishing of flat sheet metal (SS, CS, Aluminum) |

| Optional Features | Water Spray for Cooling, Automatic Thickness Detection, Dust Collector |

Types of Sheet Metal Edge Deburring Machines

- Belt Deburring Machines: Use abrasive belts that rotate to smooth and round off edges. Ideal for removing burrs quickly from flat sheets.

- Brush Deburring Machines: Utilize rotary brushes that polish edges and remove light burrs, often used for finishing softer metals or delicate parts.

- Combination Machines: Some systems combine belts and brushes for more comprehensive edge finishing in a single pass.

Why Use a Sheet Metal Edge Deburring Machine?

- Improved Product Quality: Burr-free edges improve the appearance and functionality of metal parts, making them ready for assembly or painting.

- Worker Safety: Sharp edges are a common cause of cuts and injuries; deburring eliminates this hazard.

- Process Efficiency: Automating deburring reduces labor time and costs, while increasing throughput.

- Compliance: Many industries require parts to meet strict edge quality standards to ensure safety and reliability.

Choosing the Right Sheet Metal Edge Deburring Machine

When selecting a deburring machine, consider factors such as the size and thickness of your sheet metal, production volume, and material type. It’s also important to choose a machine that offers adjustable settings and easy maintenance.

Conclusion

A sheet metal edge deburring machine is an essential tool in modern metal fabrication, helping manufacturers deliver smooth, safe, and high-quality metal components efficiently. Whether for small workshops or large industrial operations, investing in the right deburring equipment can enhance productivity, reduce costs, and improve overall product quality.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao