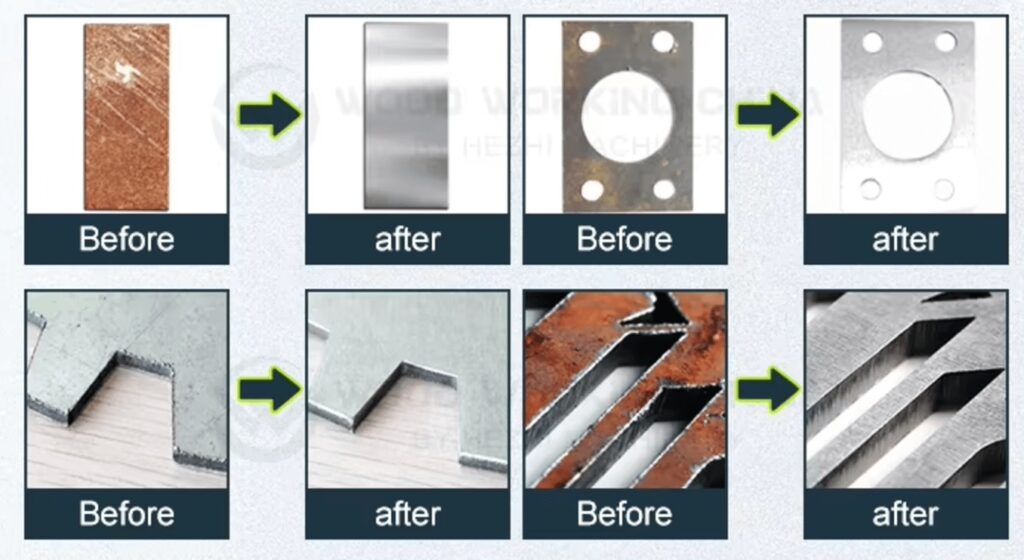

Versatility of Metal Sanders Machines Across Materials

Whether working with stainless steel, aluminum, or brass, these machines ensure surfaces are smooth, defect-free, and ready for further processing. Their adaptability to different materials makes them a must-have for industries requiring high-quality finishes and productivity.

Table of Contents

Processing Stainless Steel

Metal sanders machines are highly effective in processing stainless steel, a material often used in industries like construction and kitchenware. These machines remove burrs, weld marks, and oxidation, ensuring a polished and refined finish. The precision of metal sanders machines helps maintain the integrity of stainless steel, a critical factor in applications requiring corrosion resistance and durability.

Sanding Aluminum with Precision

Aluminum, being softer and more heat-sensitive than steel, requires a gentle yet efficient approach. Metal sanders machines are equipped with adjustable speed and pressure controls to accommodate this. By fine-tuning these settings, operators can effectively remove imperfections while preventing overheating or surface damage, ensuring a smooth and even finish.

Enhancing Brass Surface Quality

Brass, prized for its aesthetic appeal and conductivity, benefits from the precise capabilities of metal sanders machines. These machines effortlessly remove oxidation and surface flaws, delivering a brilliant and polished appearance suitable for decorative and functional applications.

Industry Applications of Metal Sanders Machines

Metal sanders machines find applications across a wide array of industries, thanks to their versatility:

- Automotive Industry: For refining parts and achieving smooth finishes on components.

- Construction: Used for preparing metal surfaces and finishing architectural elements.

- Manufacturing: Ensuring high-quality finishes on metal products for enhanced durability and appearance.

Conclusion

Metal sanders machines stand out as versatile and reliable tools capable of handling diverse metals with ease. Their adjustable settings and precision engineering make them ideal for improving productivity and quality across industries. Whether it’s stainless steel, aluminum, or brass, these machines ensure consistent, high-quality results that meet the demands of today’s metalworking standards.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao