Used Flat Metal Deburring Machines – Your Cost-Effective Finishing Solution

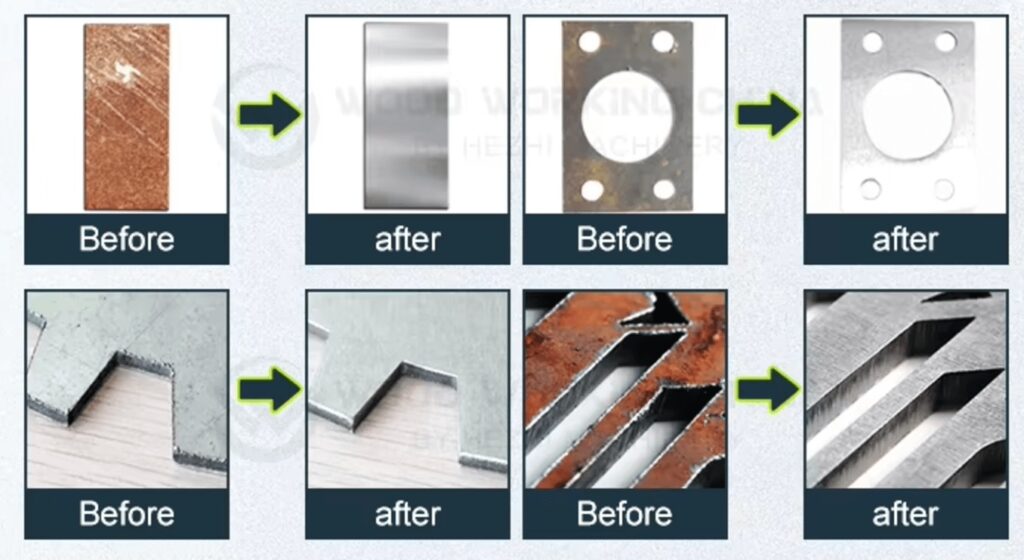

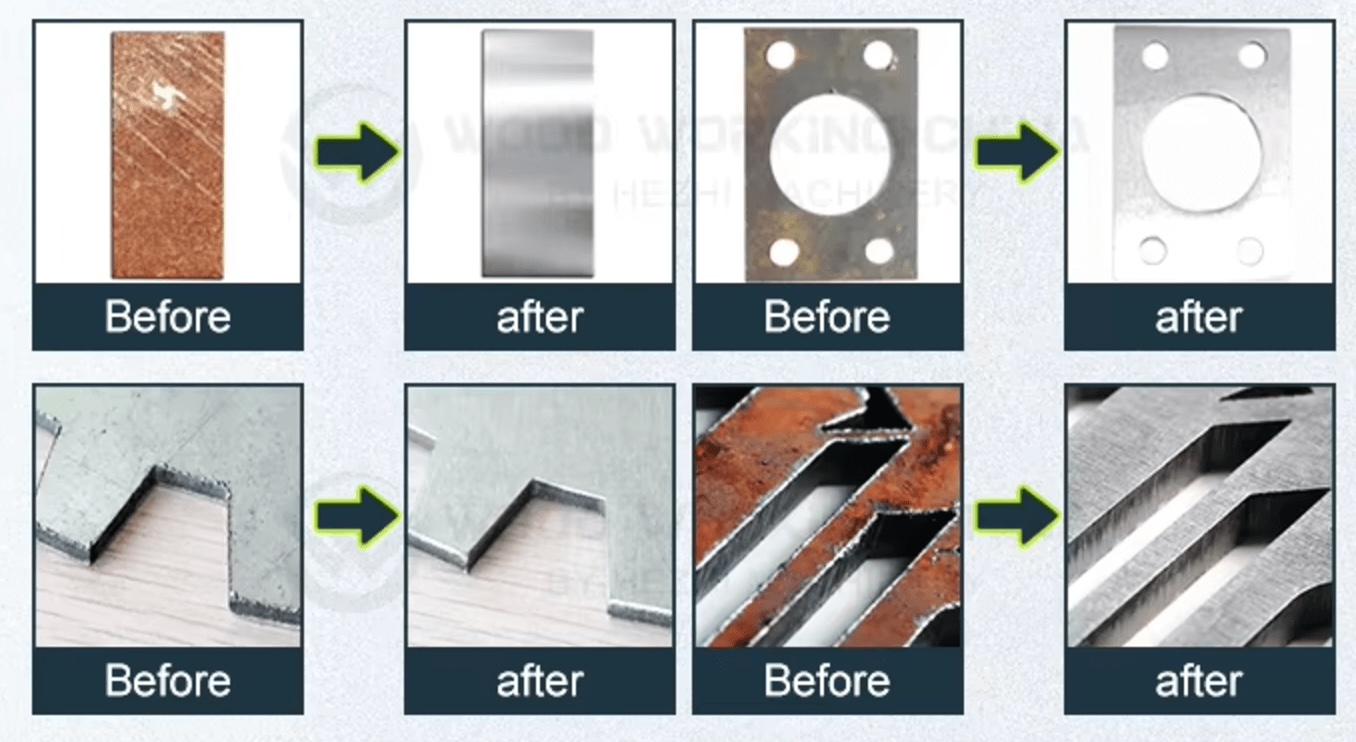

One of the most efficient ways to achieve this is by using a flat metal deburring machine. For many workshops and factories, investing in a used metal deburring machine can offer the perfect balance between performance and affordability.

Table of Contents

Why Buy a Used Flat Metal Deburring Machine?

A used flat metal deburring machine can provide the same level of precision and reliability as a brand-new model—at a significantly reduced cost. Many of these machines come from facilities that upgrade equipment regularly, meaning you can find high-quality units in excellent condition.

Advantages of buying used include:

- Lower Investment: Reduce capital expenses without sacrificing quality.

- Proven Performance: Many machines have a strong track record and come with a maintenance history.

- Faster Return on Investment: Less upfront cost means you start seeing profits sooner.

Types of Used Sheet Metal Deburring Machines

When exploring options for a used sheet metal deburring machine, understanding the available types will help you make the right choice:

- Dry Deburring Machines – Great for general burr removal and edge rounding without water cooling.

- Wet Deburring Machines – Use water to cool, clean, and reduce dust during processing.

- Automated Conveyor Deburring Systems – Ideal for high-volume production lines with continuous operation.

Key Factors to Consider Before Purchase

Before committing to a used sheet metal deburring machine for sale, inspect and evaluate:

- Condition & Maintenance History: Look for well-maintained units with minimal wear.

- Brand & Model: Choose reputable manufacturers known for long-lasting performance.

- Capacity & Compatibility: Ensure the machine handles your sheet metal size, thickness, and materials.

- Parts Availability: Confirm that replacement parts are easy to source locally or online.

RR1000 Wet Wide-Belt Sander / Deburring Machine

| Specification | Value |

|---|---|

| Working Width (Max) | 1,000 mm |

| Working Thickness | 0.8 – 80 mm |

| Minimum Part Size | 50 × 50 mm |

| Conveyor Speed | 0.5 – 6 m/min (adjustable) |

| Abrasive Belt Size | 1,910 × 1,000 mm |

| Main Motor Power | 15–22 kW |

| Total Installed Power | Approximately 30–35 kW |

| Sanding Heads | Single or dual belt heads option |

| Cooling Method | Water-based (wet) |

| Machine Weight | Approximately 2,500–3,000 kg |

Conclusion

Investing in a used flat metal deburring machine is a smart move for businesses looking to improve production quality while controlling costs. With careful selection, you can secure a machine that delivers reliable performance for years. Whether you need a used sheet metal deburring machine for small-batch work or large-scale production, the market offers excellent options to suit different needs and budgets.

For the best results, always buy from trusted suppliers who provide transparent condition reports and after-sales support. This ensures your purchase is not only cost-effective but also a long-term asset to your workshop.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao