Unlock Precision Surface Finishing with a Metal Sander Machine

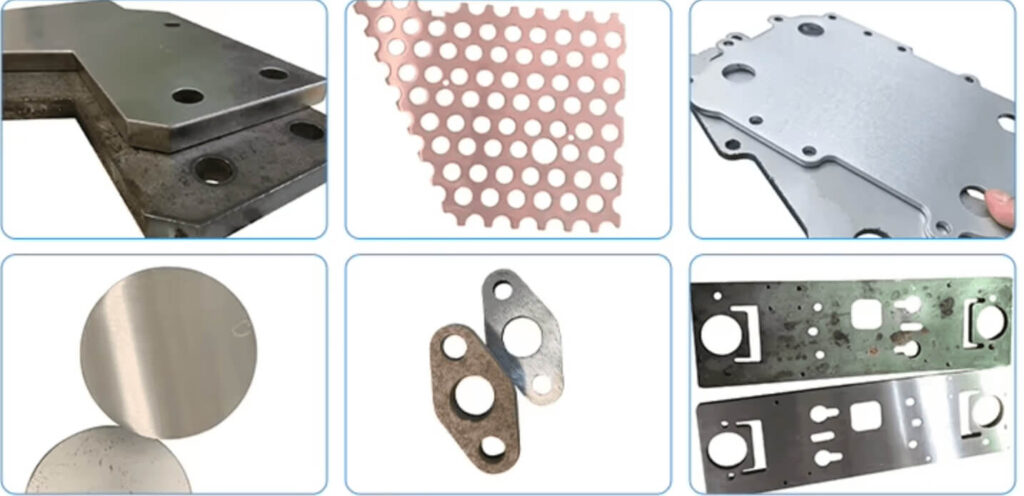

Whether you’re processing stainless steel panels, aluminum sheets, or mild steel parts, investing in the right metal sander machine can significantly enhance your workflow and final product quality.

Table of Contents

What Is a Metal Sander Machine?

A metal sander machine is an industrial-grade device designed to remove surface imperfections, rust, burrs, welding slag, and oxidation from metal parts. It utilizes sanding belts, abrasive brushes, or grinding wheels to achieve smooth, even finishes on flat, curved, or contoured metal surfaces.

These machines are commonly used in:

Metal fabrication workshops

Sheet metal production lines

Automotive and aerospace parts processing

Appliance and kitchenware manufacturing

Welding and laser cutting post-processing

Key Advantages of a Metal Sander Machine

1. Enhanced Surface Quality

Delivers consistent surface texture and gloss, whether you’re aiming for a satin finish, brushed effect, or mirror polish.

2. Time and Labor Saving

Automated sanding reduces manual labor intensity and increases throughput — perfect for batch production.

3. Material Versatility

Capable of handling stainless steel, aluminum, brass, copper, carbon steel, and even titanium.

4. Modular Configuration

Available in various working widths (e.g., 600mm, 1000mm, 1300mm) and head types (belt, brush, roller) to suit different production needs.

5. Improved Workplace Safety

Equipped with dust collection or water grinding systems to minimize airborne particles and improve environmental health.

Typical Applications

Pre-paint surface preparation

Post-laser or plasma cut edge deburring

Weld seam leveling

Sheet metal polishing

Brushed or satin surface finishing

Specifications of a Standard Metal Sander Machine

| Feature | Specification |

|---|---|

| Working Width | 1000 mm (customizable up to 1300 mm) |

| Max Sheet Thickness | 0.5 – 10 mm |

| Abrasive Type | Wide sanding belt, abrasive brush |

| Belt Speed | 5 – 20 m/min (adjustable) |

| Conveyor Speed | 0 – 15 m/min |

| Motor Power | 7.5 kW – 22 kW (depending on model) |

| Dust Collection | Integrated or external system available |

| Cooling | Optional water spray system for wet sanding |

| Control System | PLC with touch screen interface |

| Voltage | 380V / 50Hz (customizable for export) |

Conclusion

If you’re looking to upgrade your metal surface finishing process, a metal sander machine is a smart and essential investment. From deburring to polishing, this versatile machine brings consistency, speed, and professionalism to every piece of metal you process.

Contact us now for a customized quote and professional guidance on choosing the best metal sander machine for your needs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao