Types of Metal Sanding Machines and Their Applications

Each type is suitable for different metal material processing tasks. Below are the details of several common types and their applicable scenarios:

Table of Contents

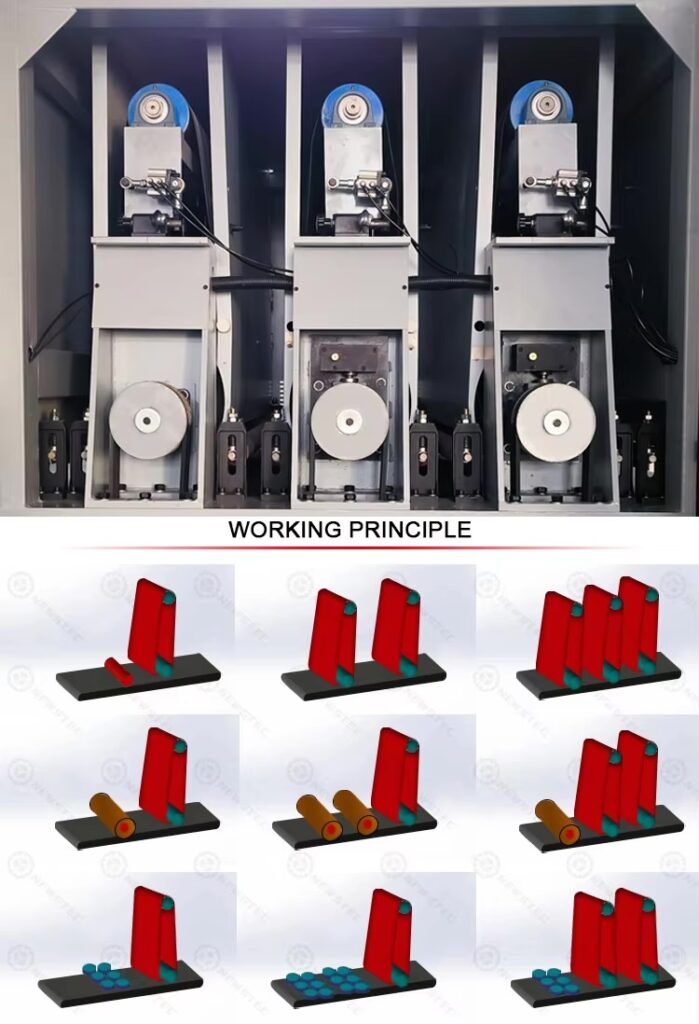

Flat Sanding Machine

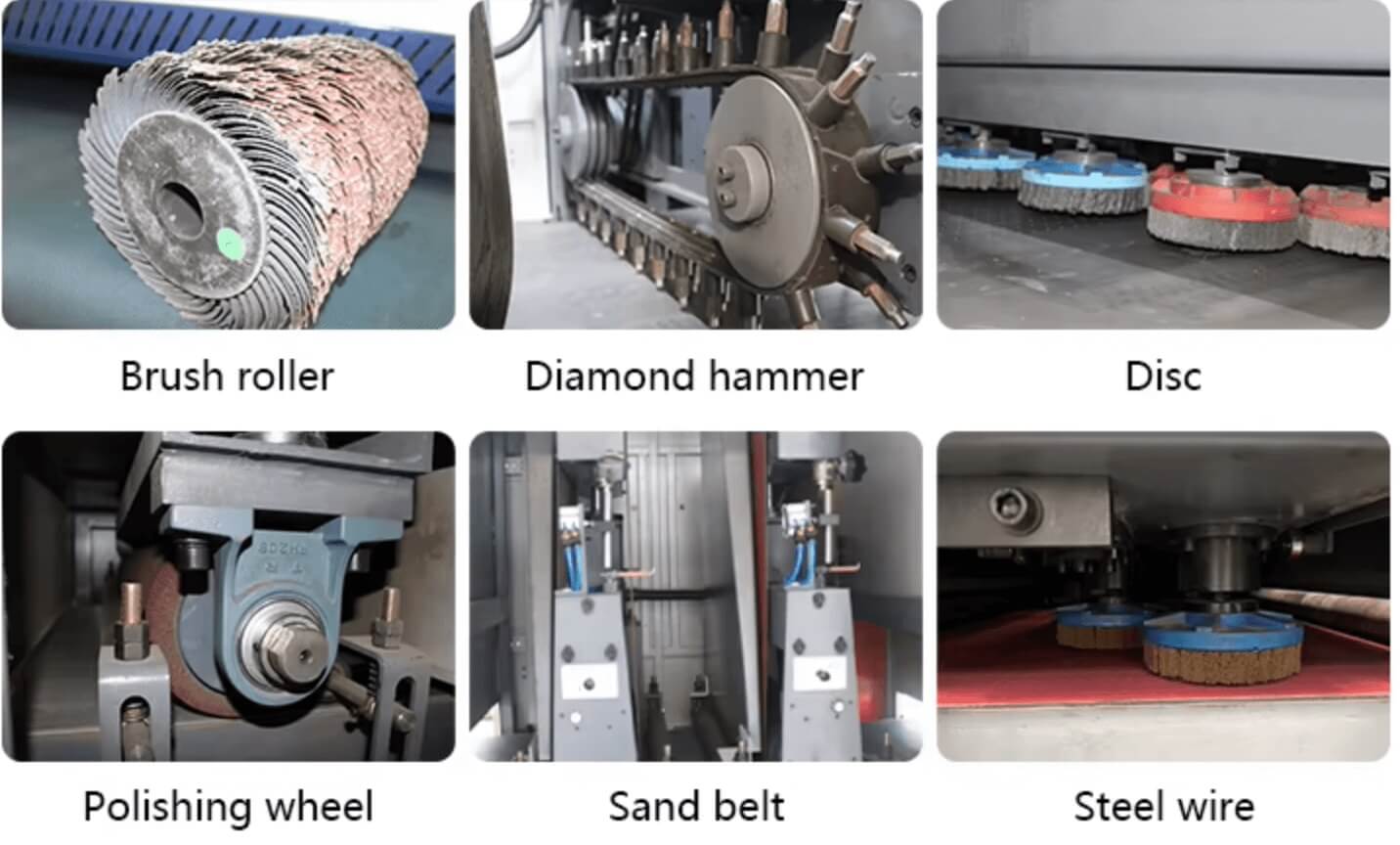

A flat sanding machine is commonly used for processing flat surfaces, efficiently removing burrs, rust, oxide layers, and irregularities on metal surfaces. It works by using sanding belts or discs for flat grinding.

- Applicable Scenarios:

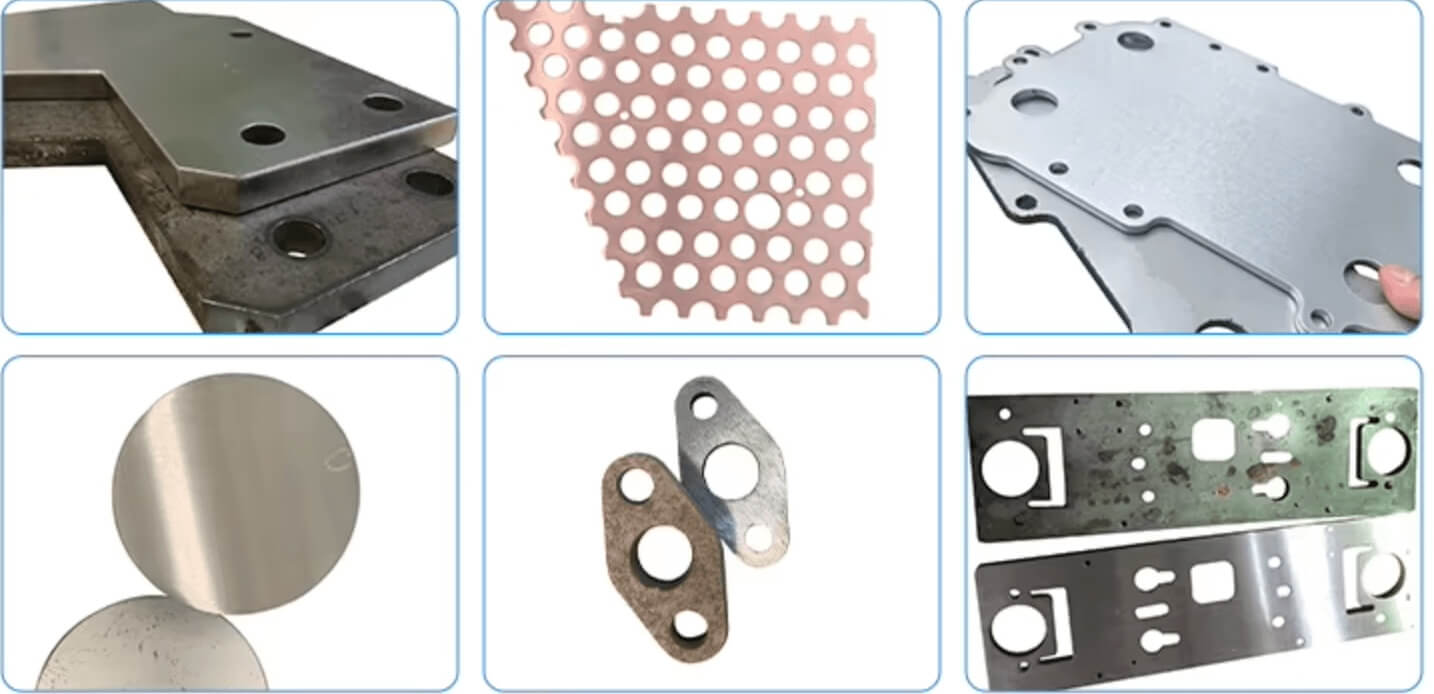

- Metal sheet processing: Such as surface treatment of stainless steel and aluminum plates, especially suitable for sanding large flat materials.

- Thin sheet metal grinding: Particularly suitable for deburring and polishing stainless steel, aluminum alloys, and other metal sheets.

- Fine grinding: For processing parts that require a high surface finish.

- Applicable Scenarios:

Belt Sanding Machine

A belt sanding machine uses a continuously running sanding belt for grinding. It is highly efficient and suitable for large-scale metal processing tasks, especially when continuous processing is required.

- Applicable Scenarios:

- Mass production: Particularly suitable for surface treatment of metal parts in large-scale production, such as automotive and home appliance components.

- Medium and large workpieces: Suitable for sanding larger-sized workpieces, improving production efficiency.

- Deburring and rust removal: Used for removing burrs and rust from metal surfaces, commonly found in metal processing workshops.

- Applicable Scenarios:

Cylindrical Sanding Machine

The sanding belt on a cylindrical sanding machine is wrapped around a cylindrical wheel, with the workpiece rotating against the belt. This type of sanding machine is generally used for more precise circular or curved processing of workpieces.

- Applicable Scenarios:

- Small metal workpiece processing: Such as deburring, polishing, and surface treatment of small metal parts.

- Processing complex-shaped parts: Suitable for processing irregularly shaped parts, such as pipes, bent pipes, or other curved metal pieces.

- High-precision polishing: Especially suited for surface finishing of metal parts that require high precision.

Conclusion

- Flat sanding machines are suitable for large-area grinding of flat surfaces, especially for metal sheet processing.

- Belt sanding machines are ideal for mass production of metal parts, offering high-efficiency surface grinding, particularly on production lines.

- Cylindrical sanding machines are suitable for small or complex-shaped metal workpieces, providing high-precision grinding for curves or detailed areas.

Choosing the appropriate type of metal sanding machine based on specific processing needs can improve production efficiency and processing quality.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao