Top Benefits of Using a Sheet Metal Edge Deburring Machine

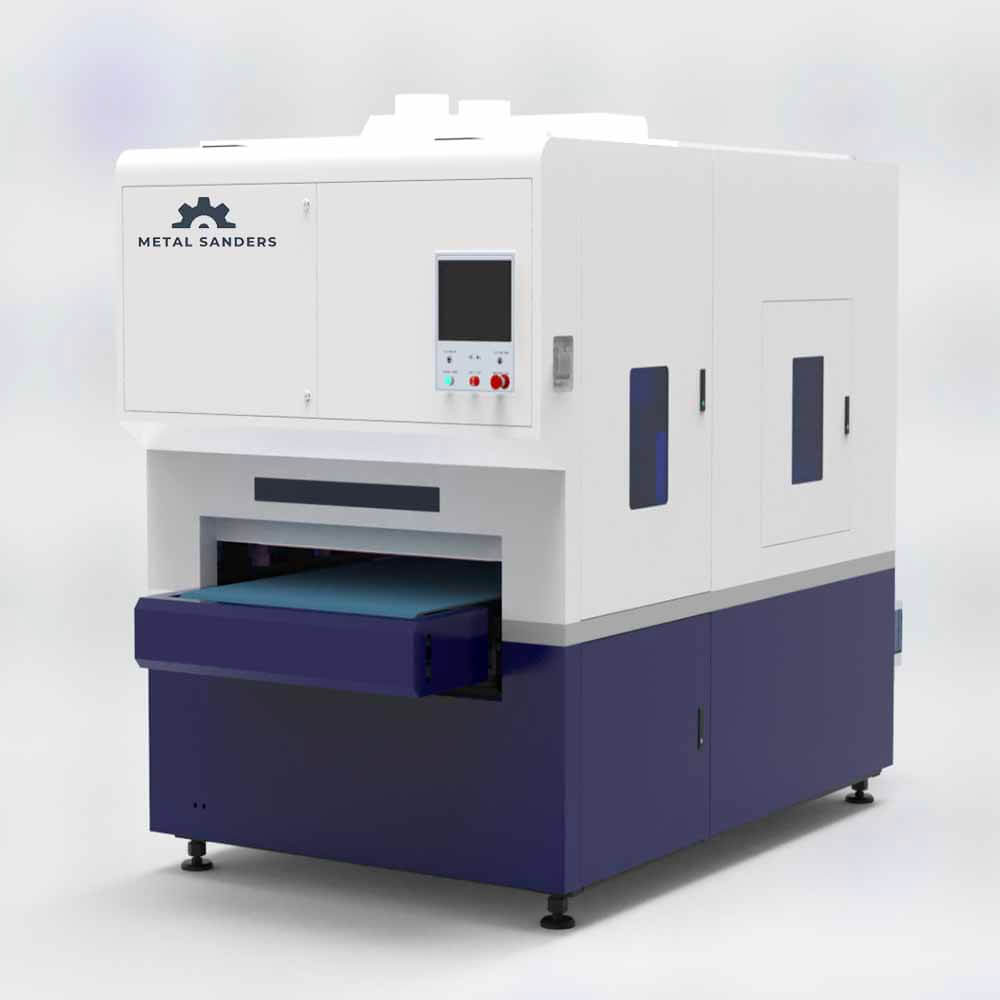

That’s where a sheet metal edge deburring machine comes into play. Investing in a deburring machine for metal sheets is a smart move that enhances quality, productivity, and workplace safety.

Table of Contents

Key Benefits of Using a Sheet Metal Edge Deburring Machine

1. Improved Edge Quality

One of the most immediate advantages of using a deburring machine for sheet metal parts is the superior edge finish it provides. It removes sharp burrs and uneven edges, creating smooth, clean lines suitable for painting, welding, or assembly.

2. Increased Workplace Safety

Sharp edges pose a significant risk to workers. A deburring machine for metal sheets eliminates these hazards, reducing the chances of cuts and injuries, and creating a safer working environment.

3. Enhanced Product Appearance

Clean, deburred edges improve the overall look of your finished products. Whether it’s for a visible panel or an internal component, the use of a sheet metal edge deburring machine ensures a professional finish that adds value.

4. Higher Efficiency and Consistency

Manual deburring is time-consuming and inconsistent. An automated deburring machine for sheet metal parts delivers uniform results across large batches, increasing productivity while maintaining consistent quality.

5. Extended Tool Life

Deburring sheet metal before moving on to machining or forming can extend the life of cutting tools and dies. Smooth surfaces reduce friction and wear, which helps minimize maintenance costs in the long term.

6. Compatibility with Automation

Modern sheet metal deburring machines are compatible with CNC lines and robotic systems. They can be integrated into your production flow, allowing for smart manufacturing and reduced labor demands.

Applications

These machines are widely used across several industries:

- Metal fabrication workshops

- Automotive component manufacturers

- HVAC ducting and enclosure producers

- Electronics and appliance panel fabrication

- Aerospace and precision engineering sectors

Conclusion

Investing in a deburring machine for sheet metal parts is not just about removing burrs—it’s about upgrading your entire production process. From safer workspaces and improved product quality to faster turnaround times and better tool preservation, the benefits of using a sheet metal edge deburring machine are both immediate and long-lasting. Whether you’re handling high volumes or focusing on high precision, this equipment is essential for modern sheet metal operations.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao