The Ideal Companion for Laser-Cut Parts: Sanding Machines

However, achieving a flawless final product requires more than just cutting—surface finishing is critical. This is where sanding machines shine as the ideal companion for laser-cut parts.

Table of Contents

Why Surface Treatment Matters for Laser-Cut Parts

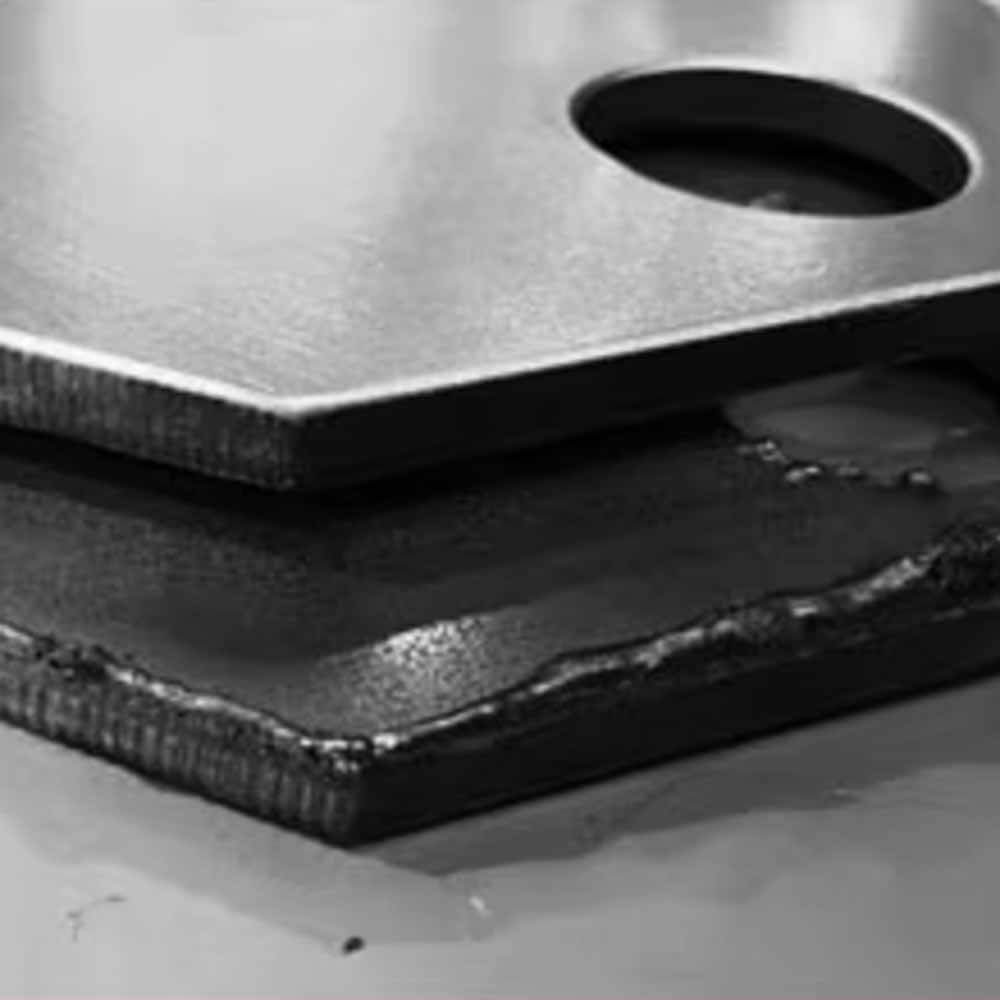

Laser cutting often leaves imperfections such as burrs, rough edges, or oxide layers on metal surfaces. These issues can compromise the aesthetic appeal, structural integrity, and compatibility with subsequent processes like coating or welding. Effective surface treatment not only enhances the product’s quality but also boosts its market competitiveness.

Advantages of Sanding Machines in Laser-Cut Surface Finishing

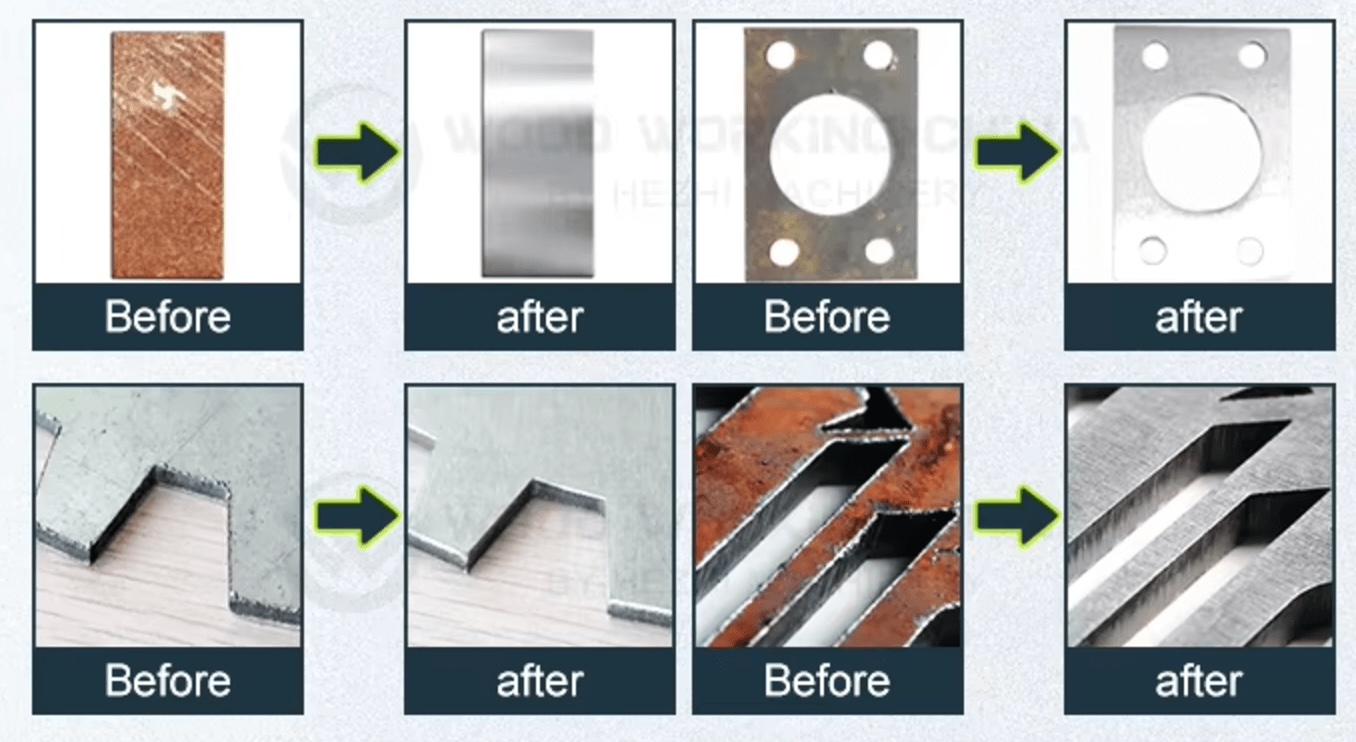

- Efficient Burr Removal: Sanding machines quickly and effectively remove burrs, ensuring a smooth edge finish.

- Oxide Layer Elimination: They clean off oxide layers from cut edges, preventing potential corrosion and improving the surface for further processing.

- Polishing Excellence: Sanding machines create a uniform and polished surface, elevating the aesthetic appeal of the final product.

- Versatility: Suitable for various metals, including stainless steel, aluminum, brass, and carbon steel.

- Consistency and Precision: Unlike manual processes, sanding machines deliver consistent results across large batches, reducing the risk of human error.

Applications Across Industries

Sanding machines are indispensable in industries such as automotive, aerospace, construction, and consumer electronics, where precise surface quality is paramount. Products with smooth and refined finishes command higher value and ensure customer satisfaction.

Conclusion

Sanding machines are the perfect partner for laser-cut parts, bridging the gap between precision cutting and impeccable surface quality. By integrating sanding machines into your production line, you can achieve superior results, improve productivity, and strengthen your competitive edge in the market.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao