The Core Role of Metal Sanding Machines in Industrial Manufacturing

They not only enhance the surface quality of products but also lay a solid foundation for subsequent processing steps. This article explores the core value of metal sanding machines from three perspectives: functional characteristics, application areas, and technical advantages.

Table of Contents

Functional Characteristics

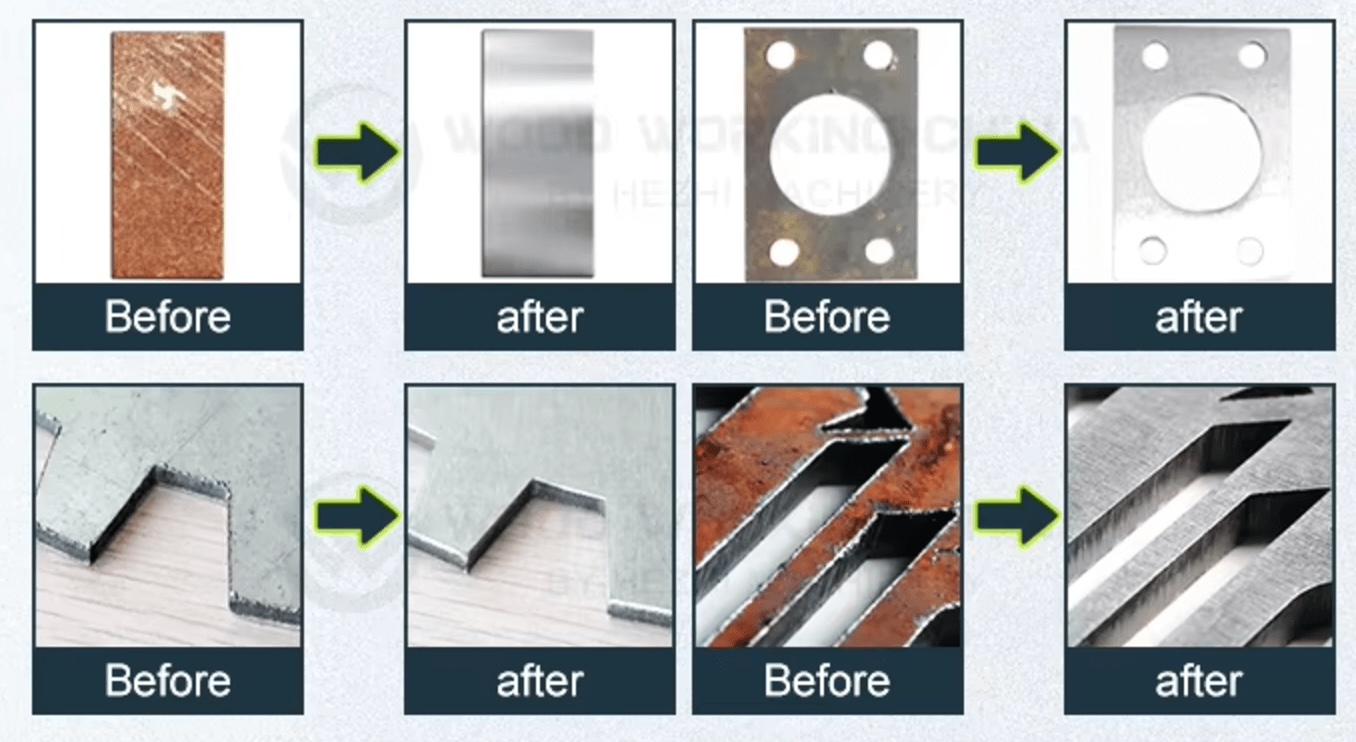

The primary function of a metal sanding machine is to perform precise grinding and polishing of metal surfaces through efficient mechanical operations. Key tasks include removing burrs, oxidation layers, and improving surface smoothness and gloss. Depending on processing needs, sanding machines are generally categorized into dry sanding machines and wet sanding machines, making them suitable for materials such as stainless steel, aluminum alloys, and carbon steel.

Application Areas

Automotive Manufacturing Metal sanding machines are used in the automotive industry for surface grinding and polishing of car body components, ensuring consistent paint quality and appearance.

Home Appliance Industry For metal casings of appliances such as refrigerators and washing machines, sanding enhances surface texture and aesthetics.

Metal Products High-precision metal products like cookware and window frames benefit from sanding treatments that provide smoother edges and superior product quality.

Technical Advantages

High Production Efficiency: Compared to traditional manual grinding, metal sanding machines significantly improve processing speed and shorten production cycles.

Consistent Quality: With precise automation control, these machines ensure high consistency in surface quality, minimizing human error.

Versatile Processing: They can be configured with different specifications of sanding belts, wheels, or heads to achieve various surface treatment effects.

Wide Compatibility: Suitable for a variety of metal materials and workpiece thicknesses, meeting diverse industrial production demands.

Conclusion

Metal sanding machines are highly valued in industrial manufacturing for their efficiency, reliability, and versatility. They not only enhance the efficiency of surface treatments but also provide strong support for precision manufacturing across various industries. As technology continues to evolve, the application scope and processing capabilities of metal sanding machines are expected to expand further, injecting new vitality into industrial manufacturing.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao