Stainless Steel Sausage Linker & Metal Deburring Sanding Machines

Whether you are in the food processing industry or metalworking, choosing the right equipment can dramatically improve productivity. Among essential machines are the Stainless Steel Sausage Linker Machine, the Hot Selling Flat Sheet Metal Deburring Machine, and the Heavy Duty Wide Belt Sanding Machine. These machines are designed to enhance performance, reduce labor costs, and ensure high-quality output.

Table of Contents

Stainless Steel Sausage Linker Machine

A stainless steel sausage linker machine is an essential piece of equipment for meat processing facilities. It automates the linking of sausages, improving speed and consistency compared to manual operations.

Key Features:

- Made from high-quality stainless steel for durability and hygiene

- Adjustable linking length for various sausage sizes

- Efficient and fast operation for large-scale production

- Easy to clean and maintain

Applications: Sausage factories, butcher shops, and food processing plants that require reliable, high-speed sausage linking.

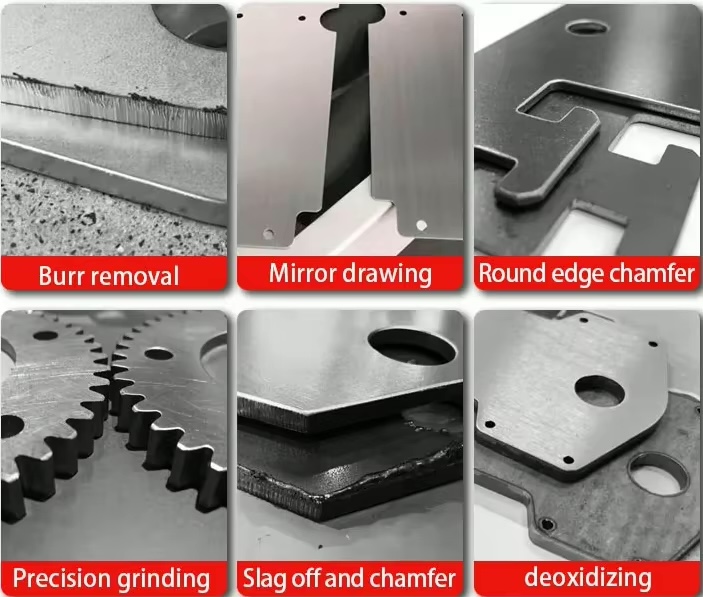

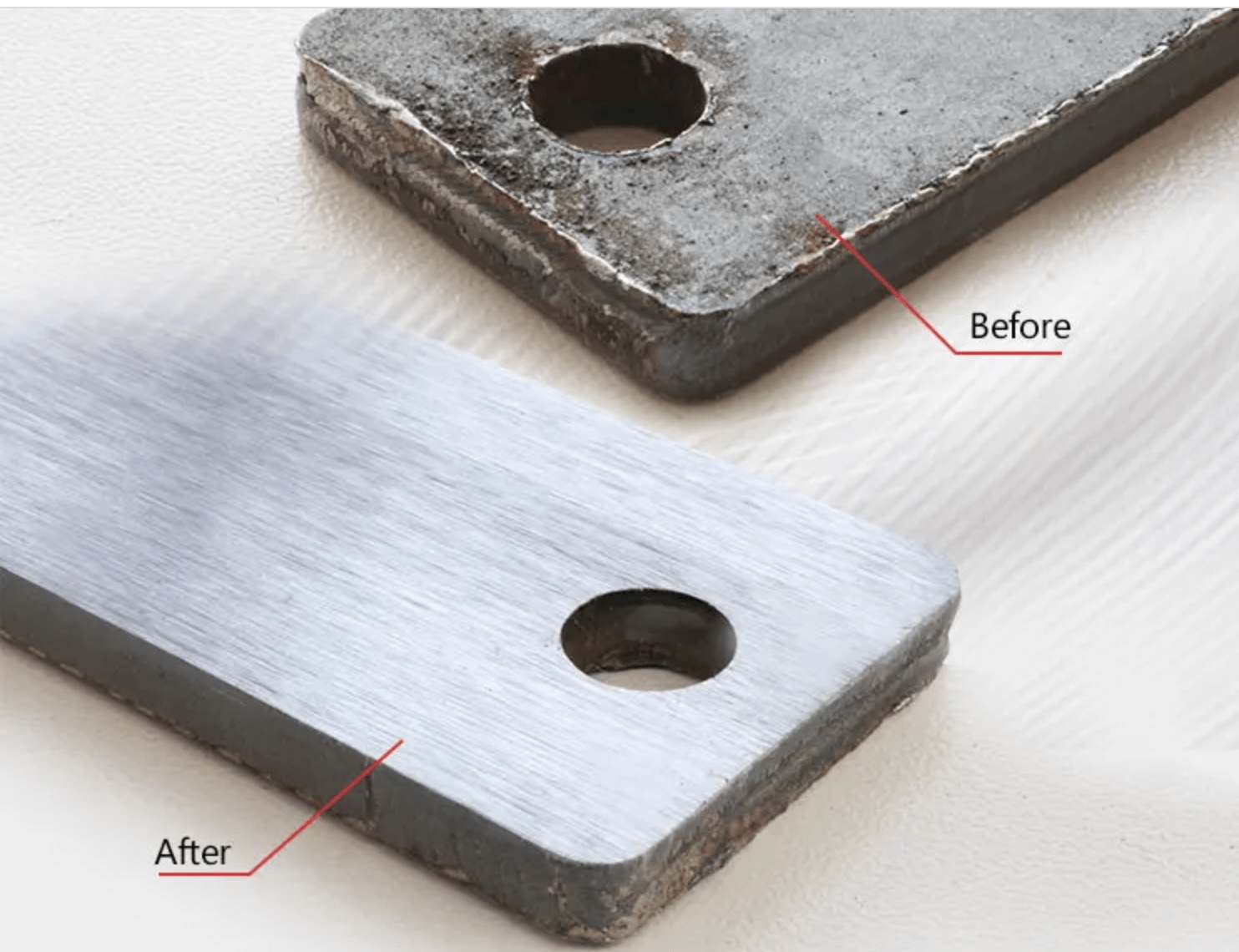

Hot Selling Flat Sheet Metal Deburring Machine

Metalworking requires precise finishing to ensure smooth edges and safe handling. The hot selling flat sheet metal deburring machine is designed for this purpose, providing a fast, efficient solution for removing burrs and sharp edges.

Advantages:

- Ideal for stainless steel, aluminum, and other sheet metals

- Reduces manual labor and improves production efficiency

- High-precision deburring ensures smooth, safe edges

- Compact and durable design for heavy-duty industrial use

Applications: Sheet metal fabrication, automotive parts production, and metal workshop finishing.

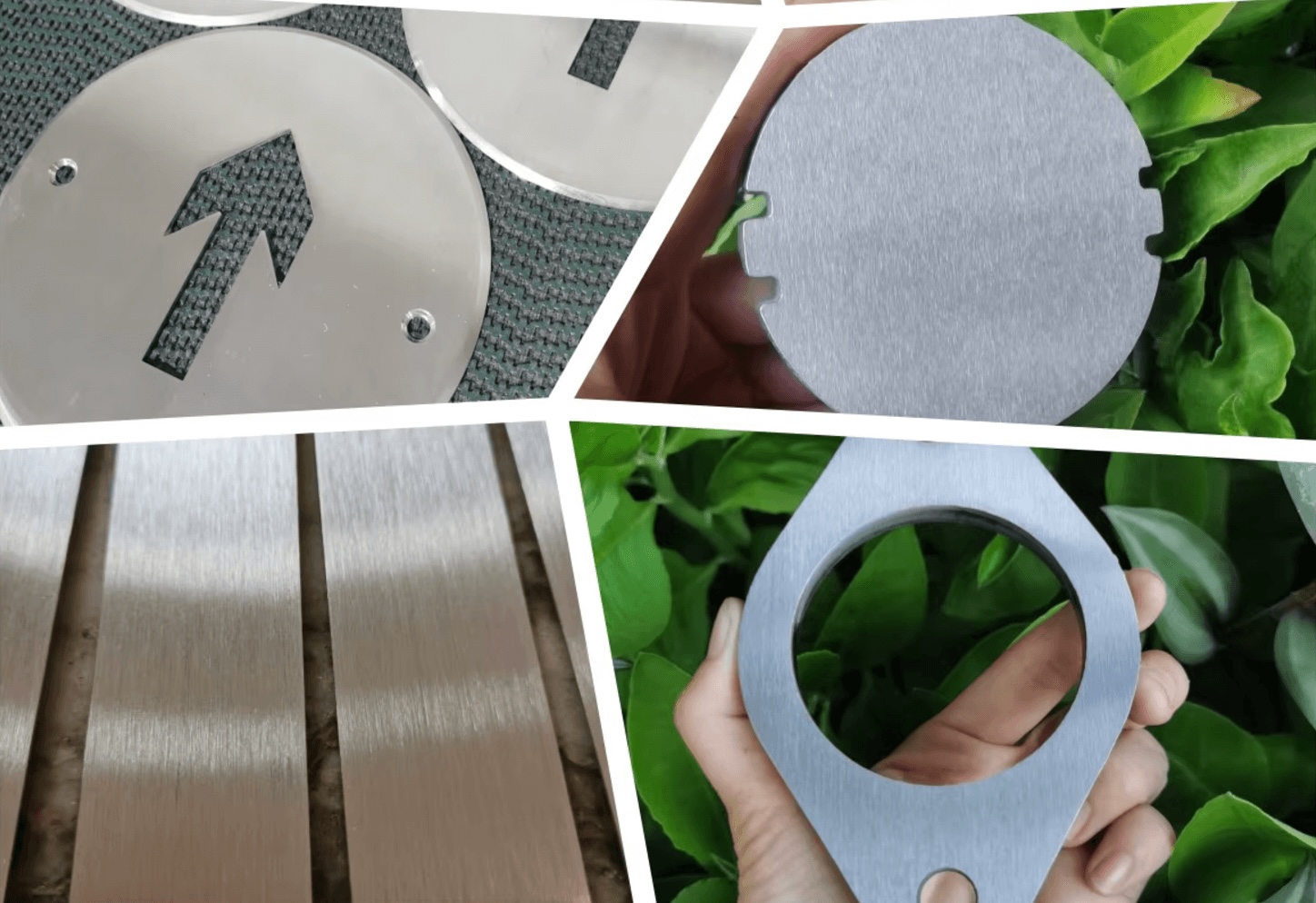

Heavy Duty Wide Belt Sanding Machine

The heavy duty wide belt sanding machine is designed to handle large surfaces and tough materials, ensuring smooth finishes for metal, wood, or composite sheets. Its robust construction allows for continuous, high-performance operation.

Key Features:

- Wide belt design for maximum coverage and efficiency

- Adjustable speed and sanding pressure for different materials

- Heavy-duty construction for long-term durability

- Suitable for large-scale industrial applications

Applications: Metal fabrication, woodworking factories, furniture manufacturing, and surface finishing workshops.

Metal Sander Machine Specification Table

| Parameter | Specification |

|---|---|

| Model | RR-R1300 |

| Working Width | 1300 mm |

| Working Thickness | 0.5 – 120 mm |

| Abrasive Belt Size | 1330 × 2200 mm |

| Feeding Speed | 5 – 30 m/min (adjustable) |

| Main Motor Power | 37 kW |

| Feeding Motor Power | 2.2 kW |

| Lift Motor Power | 0.55 kW |

| Vacuum Pump Power | 5.5 kW |

| Total Power | 45 kW |

| Abrasive Belt Type | Wide Belt + Rotary Brush |

| Control System | PLC with Touch Screen |

| Dust Collection Port | 150 mm × 3 |

| Machine Dimensions | 2620 × 2100 × 2100 mm |

| Machine Weight | 4800 kg |

Why Invest in High-Quality Industrial Machines?

- Efficiency: Automate time-consuming processes like sausage linking, deburring, and sanding

- Precision: Achieve consistent, high-quality results every time

- Durability: Built to handle continuous heavy-duty operation

- Cost Savings: Reduce labor costs and improve production speed

Conclusion

From food processing to metalworking, investing in the right machinery is key to productivity and quality. A stainless steel sausage linker machine ensures efficient food production, a hot selling flat sheet metal deburring machine provides precise finishing for metal sheets, and a heavy duty wide belt sanding machine delivers smooth surfaces for large industrial projects.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao