Stainless Steel Flat Polishing Grinding Machine – Flat Bar Belt Surface Deburring & Polishing Solution

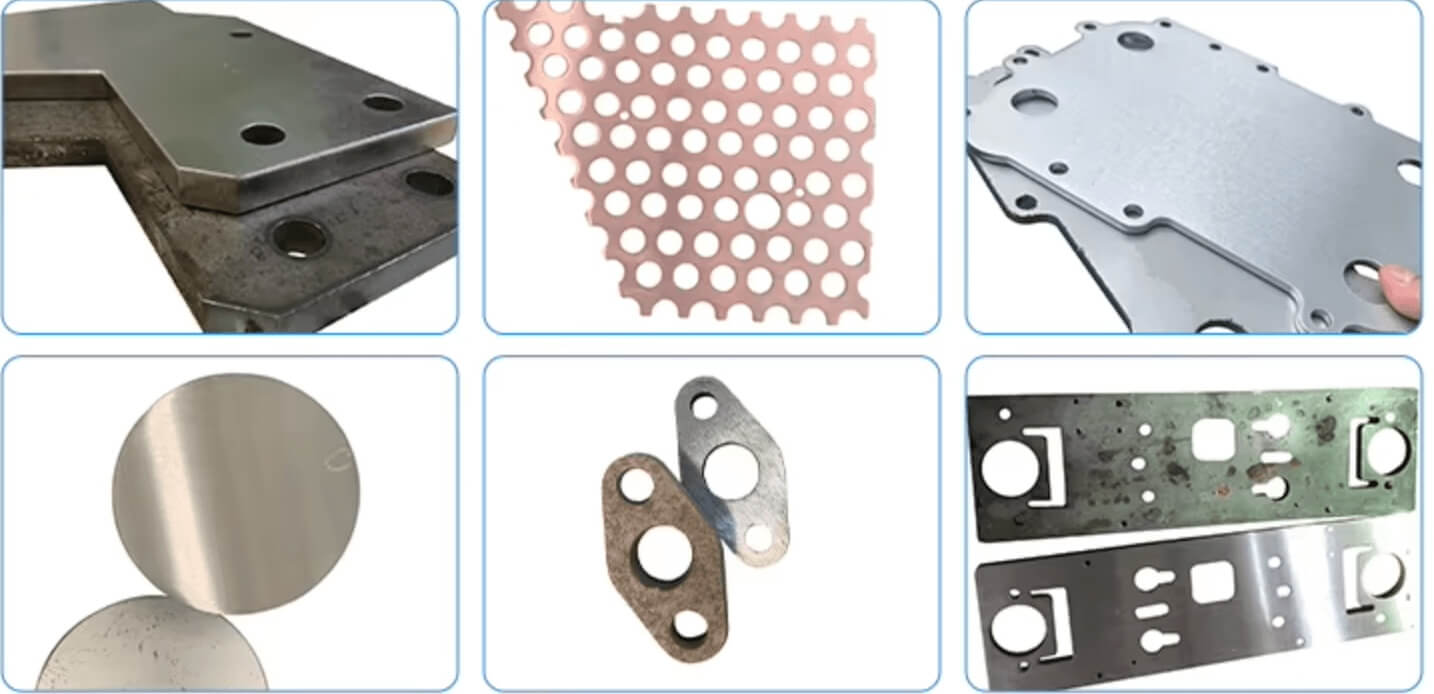

Ideal for processing flat bars, square tubes, or sheet metal parts, this stainless steel flat polishing machine delivers consistent surface finishes, eliminates burrs, and improves product quality. It is widely used in metal fabrication, architectural decoration, elevator manufacturing, and kitchenware production.

Table of Contents

Key Features of the Stainless Steel Flat Polishing Grinding Machine

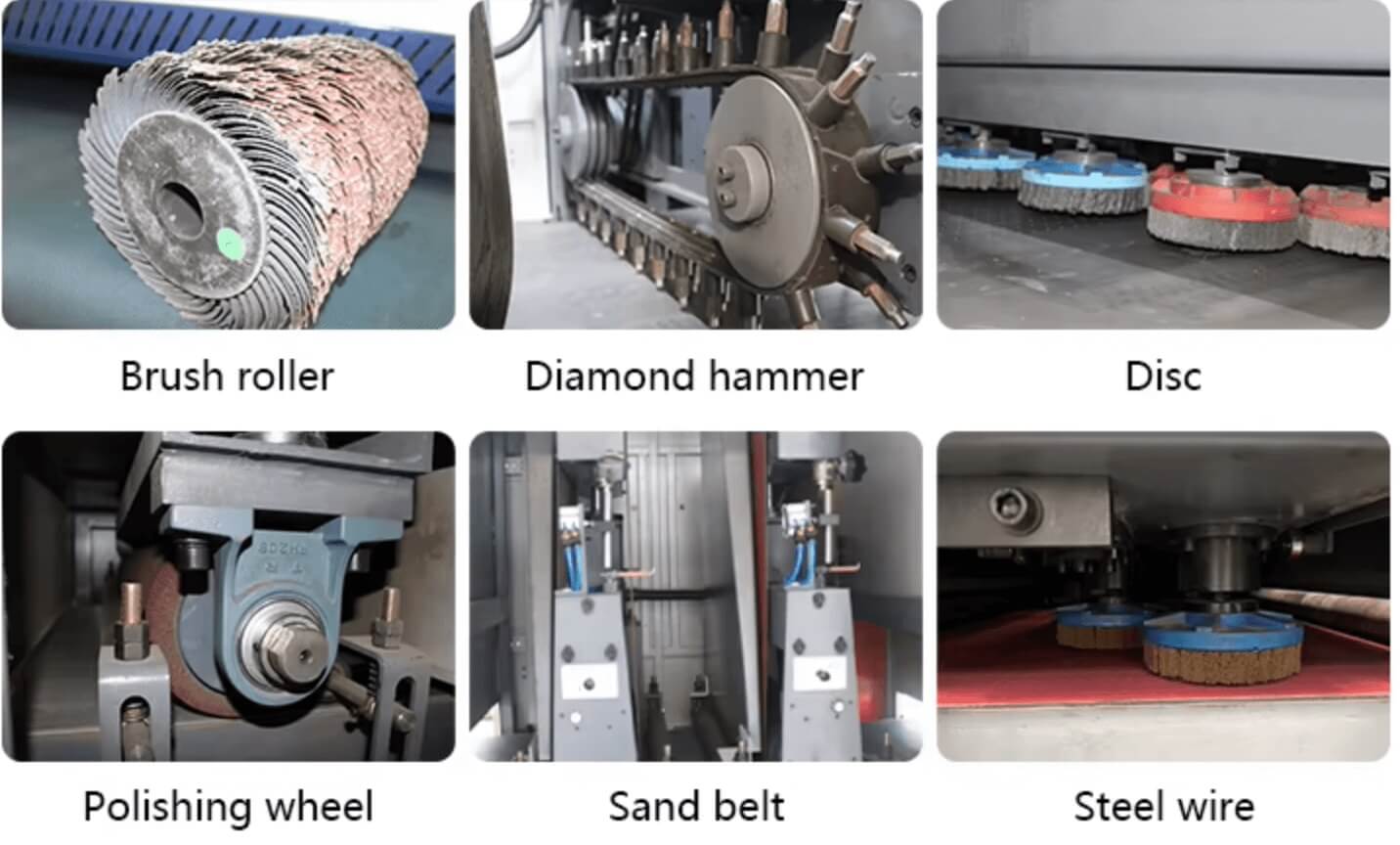

- Heavy-Duty Flat Belt Grinding System

Equipped with a high-torque abrasive belt, the flat bar belt surface sheet metal deburring polishing grinding machine handles a wide range of materials and thicknesses with ease, delivering uniform results across the entire surface. - High-Precision Surface Polishing

The stainless steel flat polishing machine delivers mirror or satin finishes based on the abrasive type and polishing configuration. Ideal for decorative stainless steel panels or components. - Efficient Deburring Function

Designed as a flat bar belt surface deburring machine, it removes sharp edges, laser slag, and oxide skin after cutting or welding processes, improving safety and downstream assembly. - Adjustable Pressure & Speed Control

The operator can fine-tune belt pressure, feeding speed, and polishing direction via the user-friendly control panel, ensuring optimal surface treatment results for each workpiece. - Versatile Worktable Design

The machine accommodates a wide range of flat materials including stainless steel flat bars, aluminum sheets, and copper strips. Magnetic or vacuum fixtures are available for thin part stabilization. - Low Noise & Dust Collection System

Built-in dust ports and noise-reducing enclosures make this metal polishing machine suitable for clean and quiet production environments.

Applications

This stainless steel flat polishing machine is suitable for:

Stainless steel sheet polishing for elevators, panels, and cabinets

Flat bar and strip polishing in kitchenware or architectural industries

Deburring and oxide removal from plasma or laser-cut aluminum and stainless parts

Its multifunctional capabilities make it an ideal flat bar belt surface sheet metal deburring polishing grinding machine for high-precision industrial use.

Technical Specifications

| Parameter | Value |

|---|---|

| Working Width | 100–600 mm |

| Workpiece Thickness | 0.8–100 mm |

| Abrasive Belt Size | 1900 × 100 mm |

| Main Motor Power | 7.5 kW / 11 kW / optional |

| Feeding Speed | 1–15 m/min (adjustable) |

| Control System | Touch screen / PLC optional |

| Dust Collection Ports | 2 × 100 mm diameter |

| Machine Dimensions | 2200 × 1400 × 1700 mm |

| Machine Weight | ~1500 kg |

Why Choose This Industrial Metal Sander?

- Enhanced Efficiency & Surface Quality

Achieve consistent results on flat stainless steel parts, improving appearance and reducing manual polishing costs. - Wide Material Compatibility

Process stainless steel, aluminum, and copper with one machine—no need to switch equipment for different materials. - Customizable Configuration

Available with multiple polishing heads, automatic feeding tables, and optional wet grinding features. - High Return on Investment

Reduce rework, labor costs, and downtime while maintaining premium finish standards for demanding industries.

Conclusion

Whether you’re working with flat stainless steel panels, aluminum plates, or copper strips, the stainless steel flat polishing grinding machine is the ultimate solution for surface finishing, deburring, and polishing. Its high-performance belt grinding system and precise controls make it a valuable asset for manufacturers seeking efficiency, quality, and versatility.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao