Stainless Steel Deburring Machine: Efficient Edge Finishing for Metals

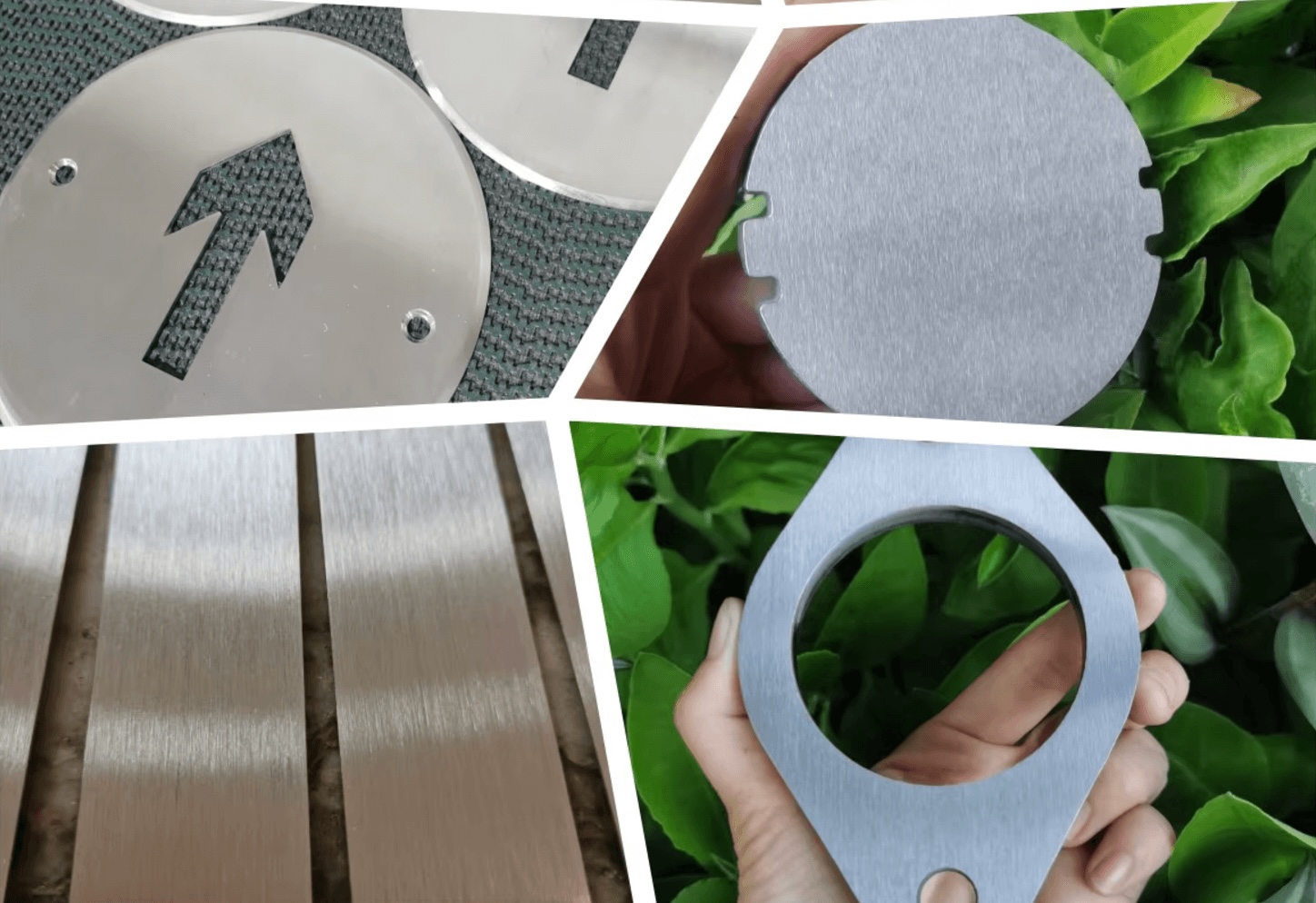

Machines like the stainless steel deburring machine, metal edge rounding machine, and metal chamfering deburring machine provide industrial solutions to automate edge finishing. They reduce labor costs, improve efficiency, and deliver consistent results across stainless steel, aluminum, brass, and other metals.

Table of Contents

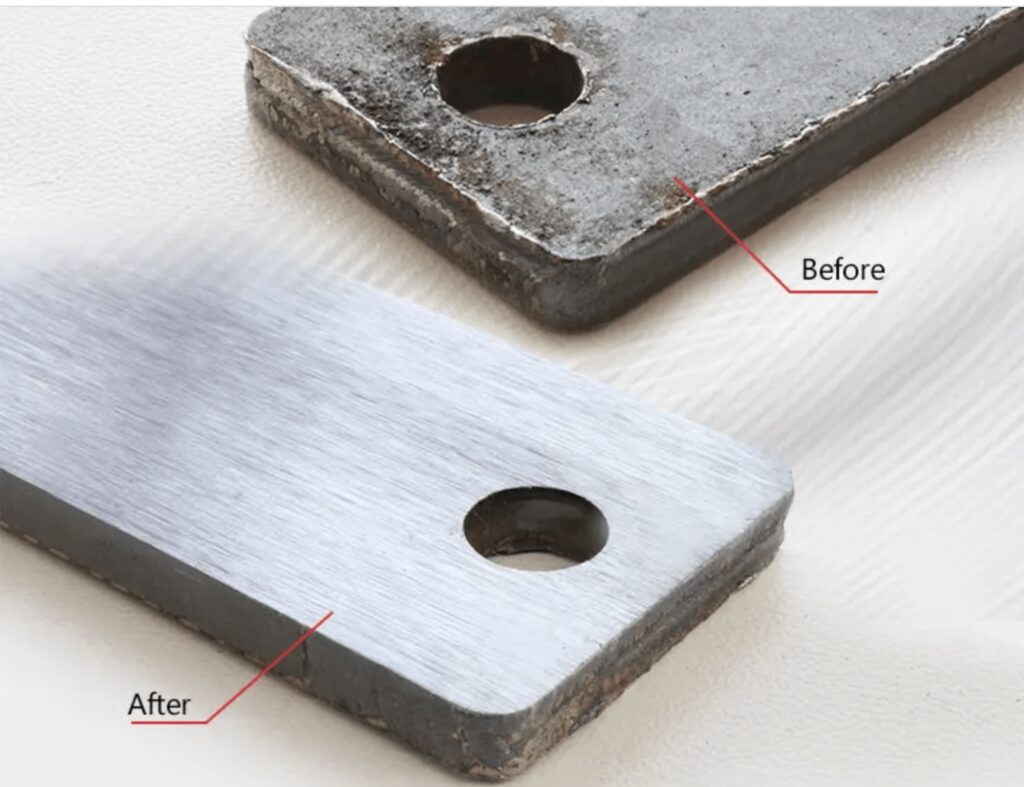

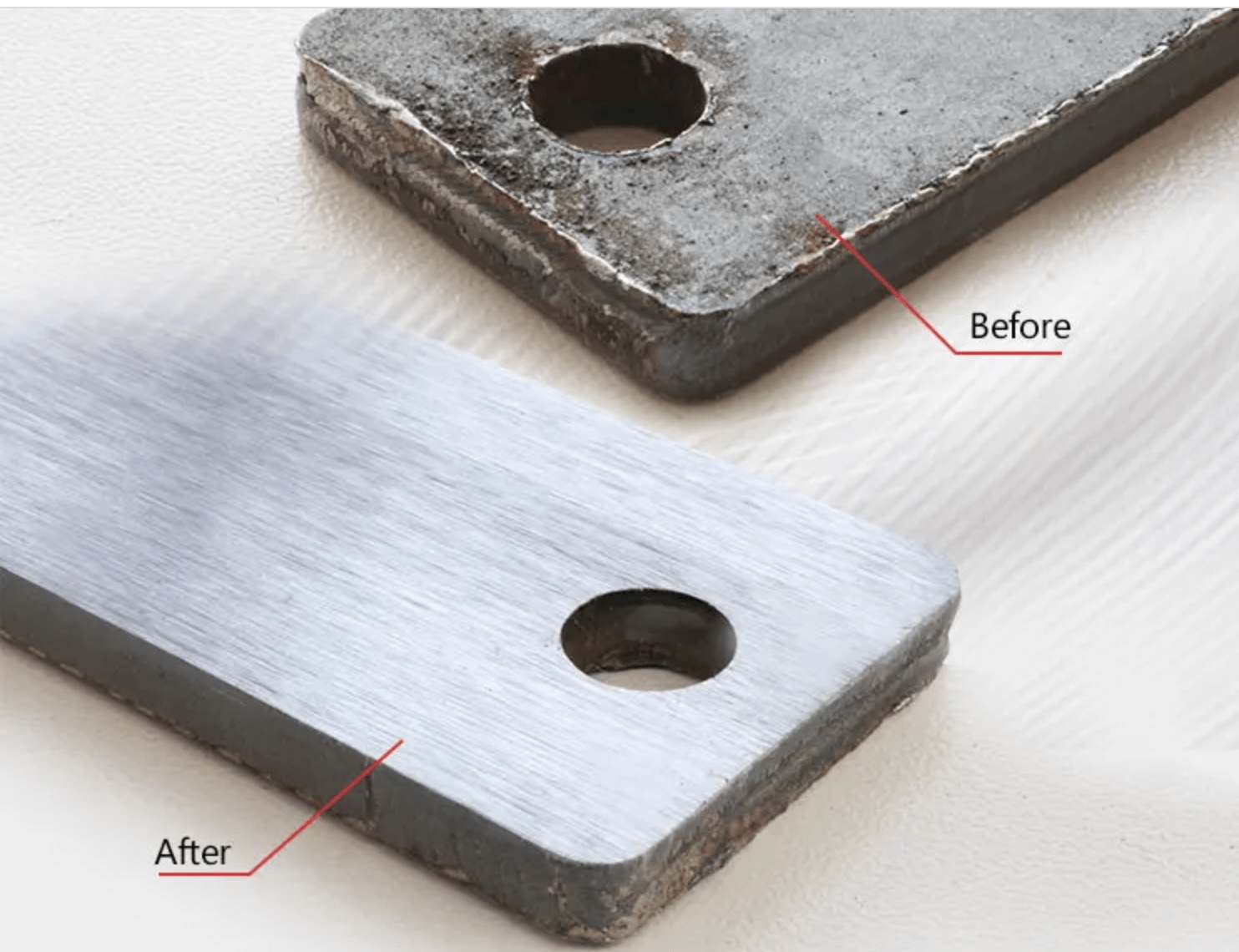

What Is a Stainless Steel Deburring Machine?

A stainless steel deburring machine is designed to remove burrs, sharp edges, and surface imperfections from stainless steel parts. It replaces labor-intensive manual finishing and ensures consistent high-quality results.

Key Features:

- High-speed rotating brushes or abrasive belts for efficient deburring

- Adjustable speed and pressure to suit different materials and thicknesses

- Robust stainless steel construction for durability and corrosion resistance

- Easy-to-use control panel for fast operation

Technical Specifications

| Parameter | Specification |

|---|---|

| Power | 3-7.5 kW |

| Motor Type | AC Motor / Spindle Motor |

| Voltage | 380V / 50Hz |

| Max Workpiece Thickness | 0-30mm |

| Belt/Brush Speed | 1000-3000 RPM |

| Working Width | 100-500mm |

| Machine Weight | 600-1200 kg |

Metal Edge Rounding Machine: Smooth and Safe Edges

The metal edge rounding machine focuses on rounding sharp metal edges, enhancing safety and aesthetics. It ensures uniform edge finishes for production-scale operations.

Advantages:

- Creates consistent rounded edges across all parts

- Improves operator safety by removing sharp corners

- Compatible with stainless steel, aluminum, brass, and other metals

- Suitable for high-volume production lines

Metal Chamfering Deburring Machine: Precision Chamfering and Polishing

A metal chamfering deburring machine removes sharp corners and creates chamfers on metal parts, preparing them for further processing like welding, coating, or assembly.

Benefits:

- Produces uniform chamfers for improved assembly and fit

- Reduces manual labor and increases production efficiency

- Works with various metals and thicknesses

- Ideal for high-precision applications

Advantages of Edge Finishing Machines

- Safety: Eliminates sharp edges and reduces the risk of injuries.

- Efficiency: Automates deburring, rounding, and chamfering processes.

- Consistency: Delivers uniform finishes for every part.

- Material Flexibility: Works on stainless steel, aluminum, brass, and other metals.

- Cost Savings: Reduces labor costs and increases production throughput.

Conclusion

For modern metalworking, investing in a stainless steel deburring machine, metal edge rounding machine, or metal chamfering deburring machine is essential. These machines improve efficiency, precision, and safety while reducing labor costs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao