Sheet Metal Wet Sander | Automatic Belt Polishing Machine

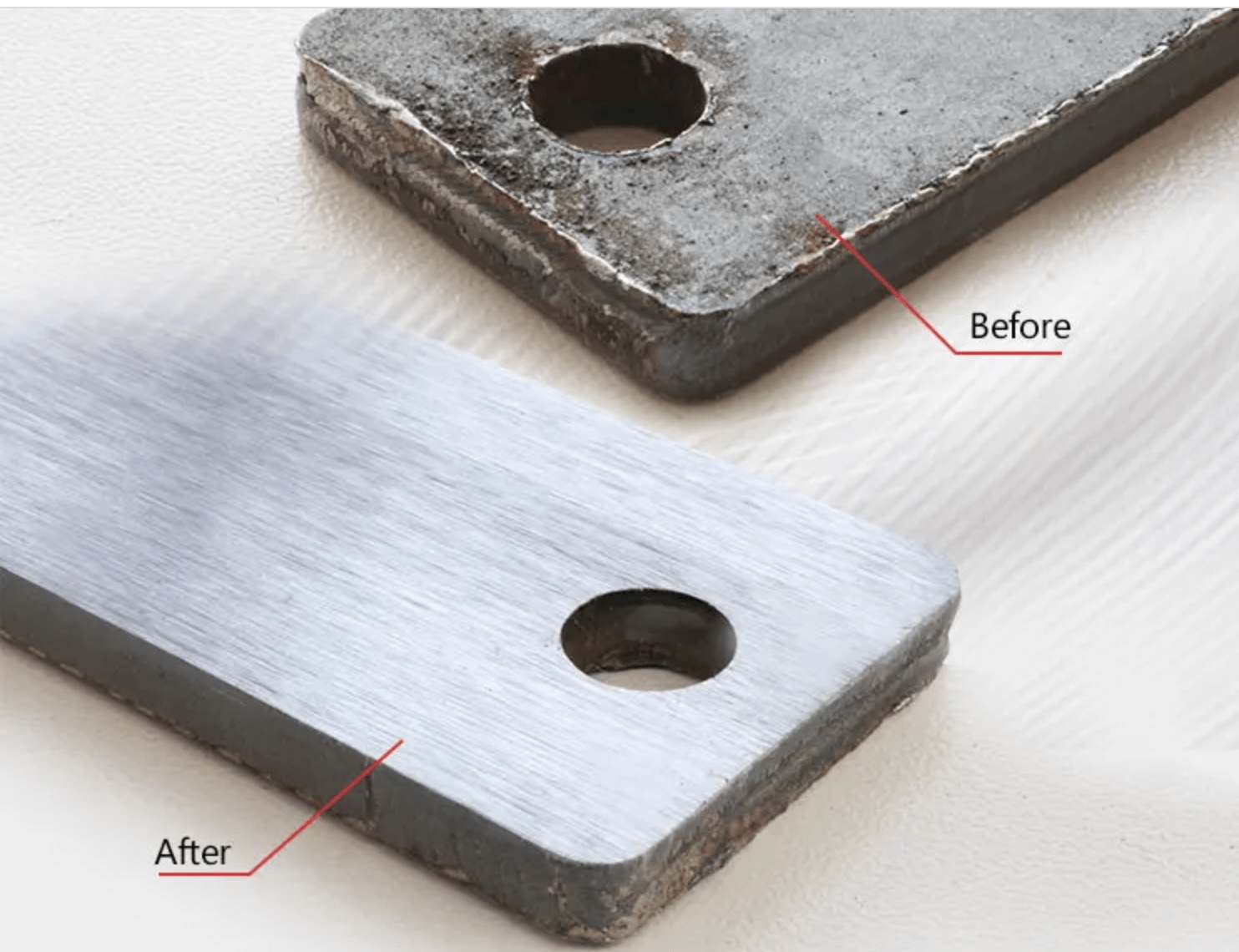

Our Automatic Wide Metal Water Wet Sander is specially engineered for industrial metal finishing applications. Whether you’re polishing stainless steel, deburring aluminum sheets, or finishing iron panels, this belt sanding and polishing machine offers consistent results with maximum efficiency.

With a built-in wet sanding system, it reduces dust and improves cooling, making it safer and more durable. It’s a must-have machine for sheet metal workshops, fabrication plants, and metal processing factories aiming for high-quality surface finishing.

Table of Contents

Key Features

- Automatic Water Wet Sanding System

Keeps the work surface cool, reduces dust, and extends belt life. - Wide Belt Design

Covers large sheet metal areas in one pass, improving efficiency. - Variable Speed Control

Allows precise control for different metal types and finishing needs. - Heavy-Duty Conveyor

Supports stable feeding of flat sheet metal with adjustable pressure rollers. - Stainless Steel Construction

Durable frame built for long-term industrial use and resistance to corrosion. - Simple Operation Panel

Easy-to-use control system with safety emergency stop.

Applications

India has become a competitive hub for engineering solutions, including sheet metal deburring machine manufacturers who deliver industrial-grade performance at affordable costs. These manufacturers offer both standard and customized solutions to match the production needs of various sectors such as aerospace, electronics, furniture, HVAC, and metal fabrication.

As a leading sheet metal deburring machine exporter, many Indian companies now supply equipment worldwide, gaining recognition for their innovation, reliability, and cost-efficiency.

Key Features to Look for in a Sheet Metal Deburring Machine

This automatic sanding and polishing machine is ideal for:

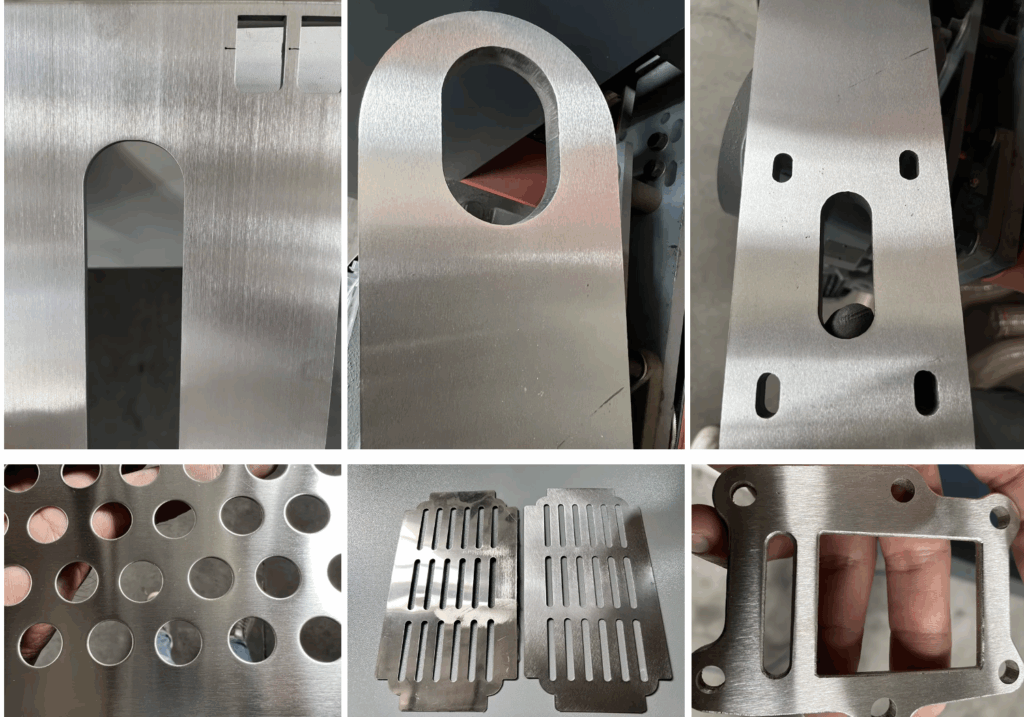

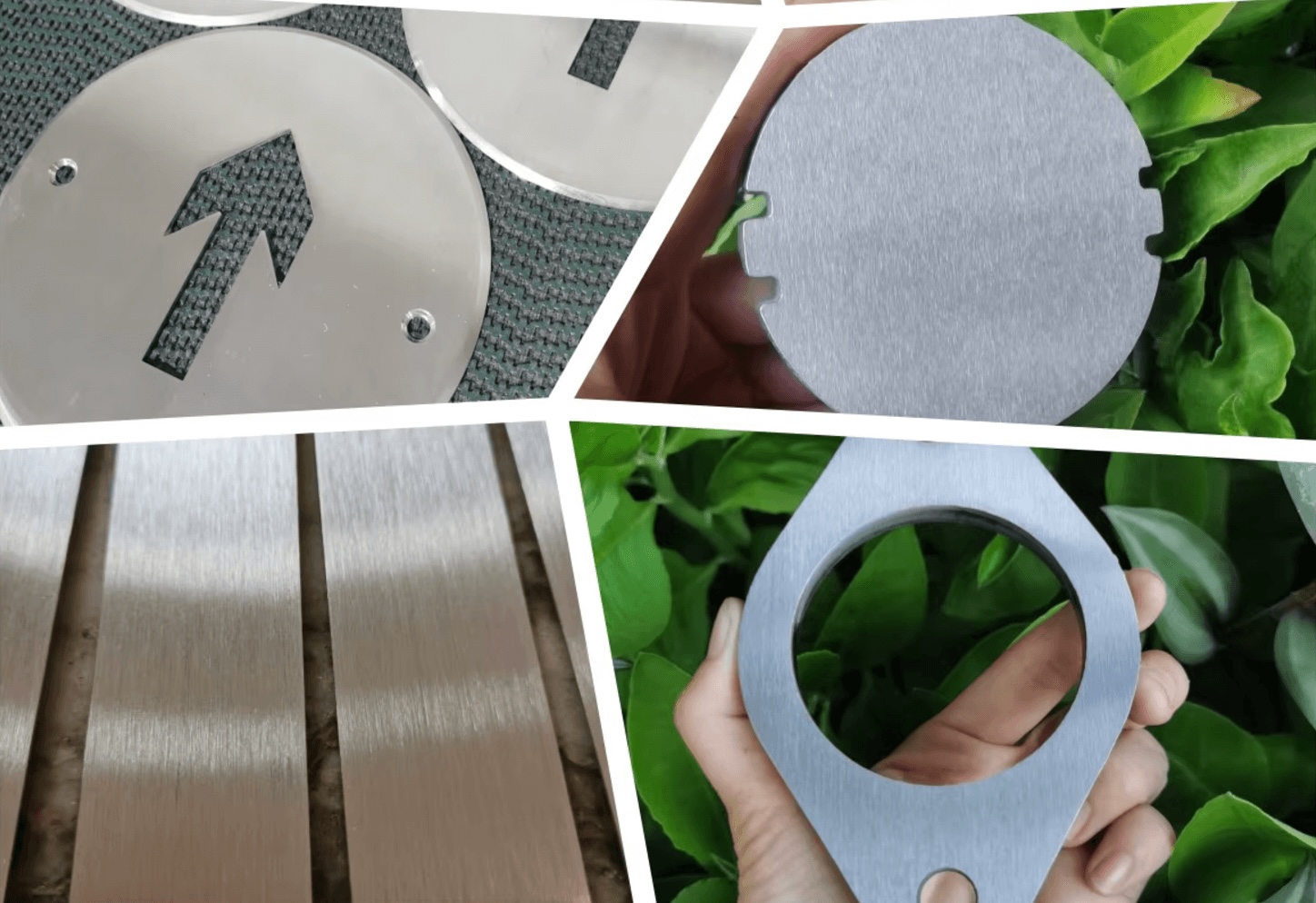

- Sheet metal deburring and polishing

- Stainless steel surface brushing

- Aluminum plate finishing

- Brass and copper sheet processing

- Laser cut, plasma cut, or punched parts

- Pre-coating surface preparation

Widely used in:

- Sheet metal workshops

- Elevator door and panel factories

- Metal furniture manufacturers

- Kitchen equipment factories

- Decorative metal processing plants

Technical Specifications

| Item | Specification |

|---|---|

| Model | MS-1300W |

| Working Width | 1300 mm (Customizable) |

| Working Thickness | 0.5 – 100 mm |

| Sanding Belt Size | 1350 x 2200 mm |

| Feeding Speed | 0.5 – 8 m/min (Adjustable) |

| Motor Power | 15 kW – 30 kW (Based on configuration) |

| Water Cooling System | Integrated with circulation pump |

| Conveyor Type | Rubber Belt with Vacuum or Roller Support |

| Control System | Touch Screen + Buttons (Optional PLC) |

| Dust Collection | Wet system with optional suction hood |

| Voltage | 380V / 50Hz / 3 Phase (Customizable) |

| Dimensions (LWH) | Approx. 2500 x 1800 x 2200 mm |

| Net Weight | About 2800 kg |

Conclusion: Your Complete Metal Finishing Solution

Looking for a reliable sheet metal sanding and polishing solution? Contact us today for a quote, machine video, or customized model. Our team is ready to help you choose the best automatic wide wet sander for your metal processing needs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao