Sheet Metal & Tube Deburring Machines | Rollei BE5 Automatic

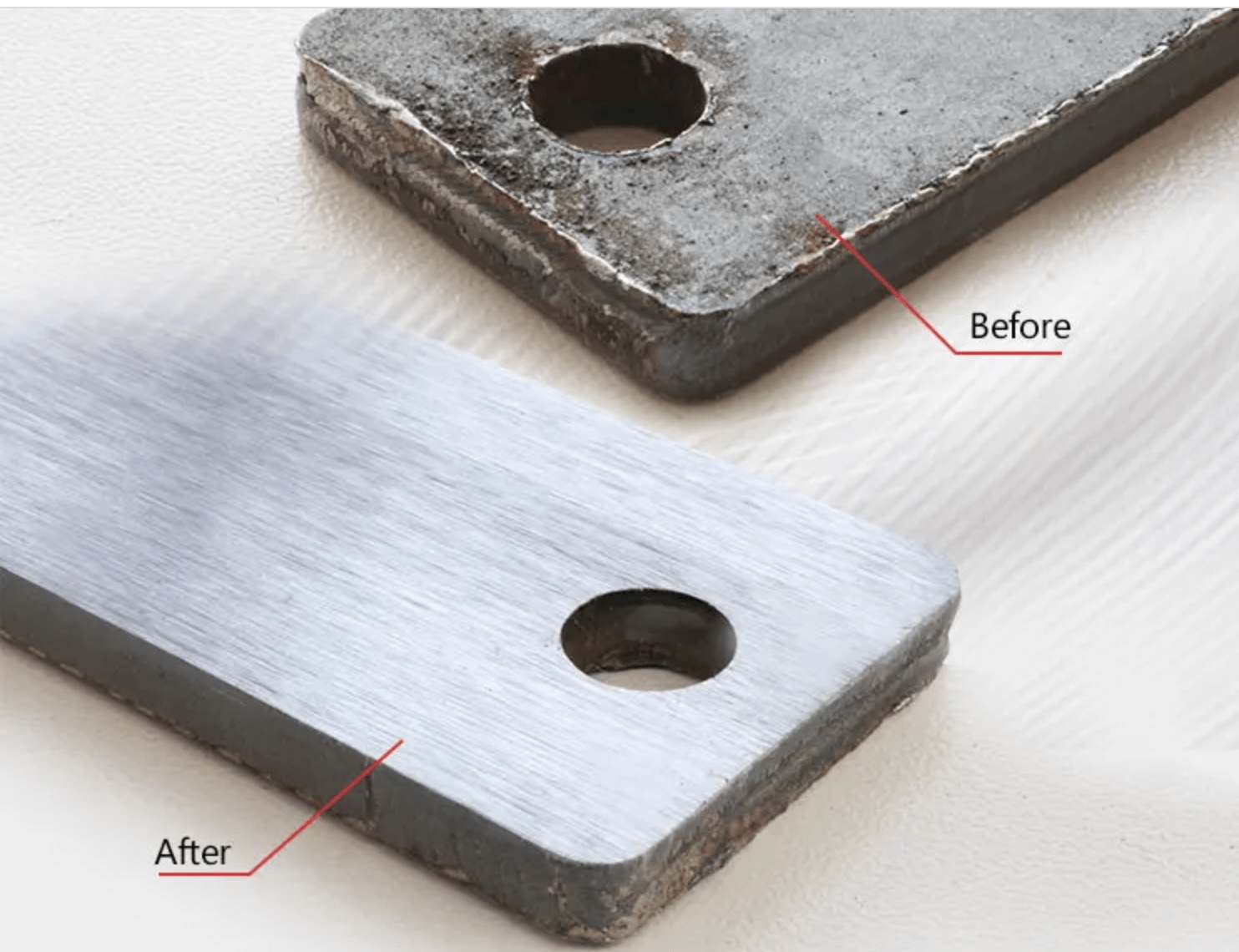

Whether you’re working with pipes, profiles, or flat sheets, burrs left behind from cutting or punching operations can compromise both appearance and function. That’s where advanced solutions like the metal tube deburring machine and the Rollei BE5 sheet metal deburring machine come into play.

Table of Contents

What is a Metal Tube Deburring Machine?

A metal tube deburring machine is specifically engineered to remove burrs, sharp edges, and surface imperfections from the ends and edges of metal tubes. It helps ensure accurate fitting, better welding results, and improved safety in handling. These machines are ideal for use in industries such as automotive, aerospace, furniture, and construction.

Key features of high-quality tube deburring machines include:

- Rotary brush or belt-based deburring heads

- Adjustable pressure and speed settings

- Compatibility with various tube diameters and materials

- Efficient dust collection systems

Rollei BE5 Sheet Metal Deburring Machine

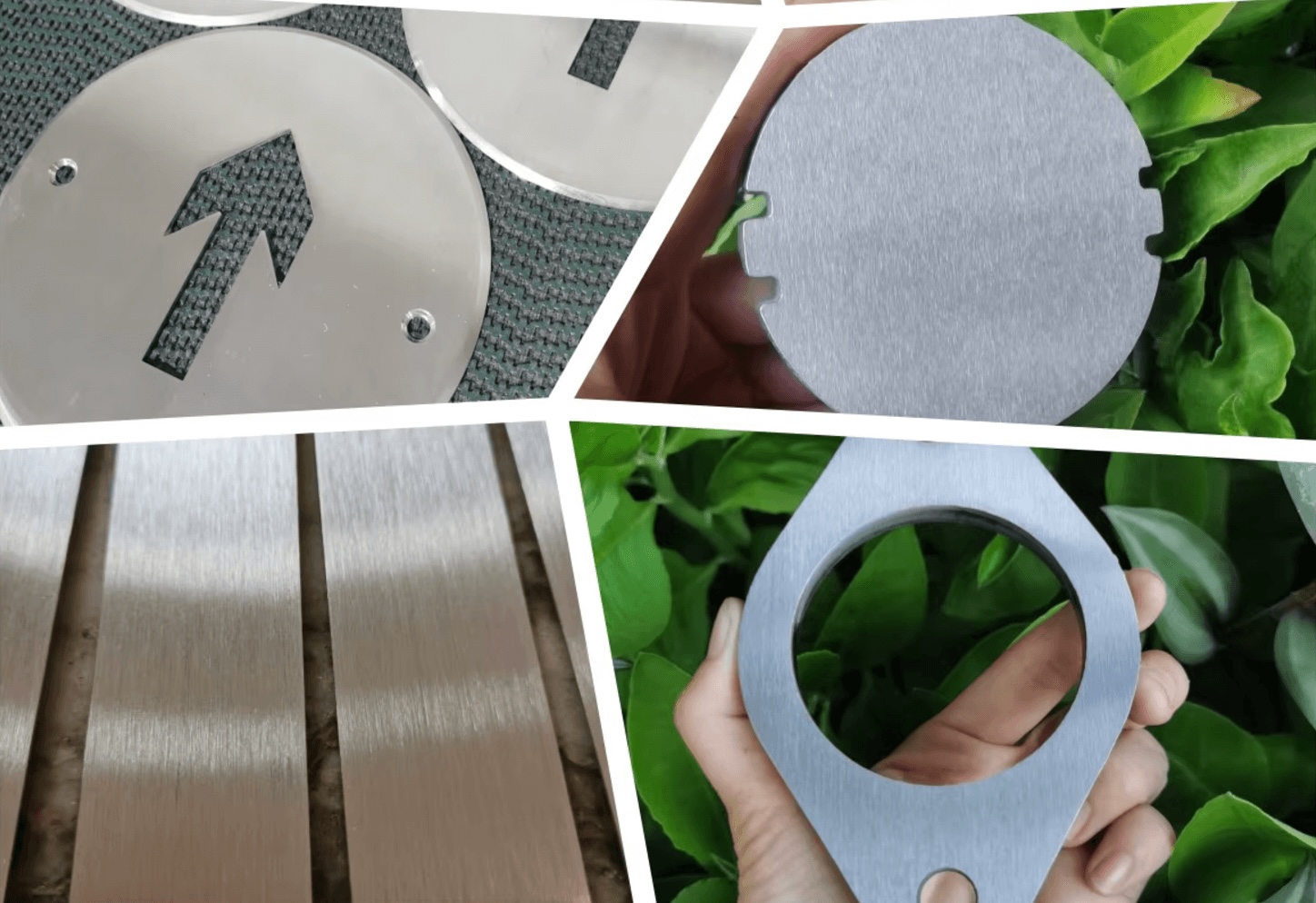

The Rollei BE5 sheet metal deburring machine is one of the most efficient systems available for flat metal sheet deburring. Designed for automatic operations, it uses a combination of sanding belts and rotating brushes to clean the edges and surfaces of metal sheets with precision and consistency.

Features of the Rollei BE5 Include:

- Dual-side processing for simultaneous top and bottom deburring

- Easy-to-use control interface for customizing settings

- Support for different material thicknesses and types (steel, stainless steel, aluminum)

- Consistent edge rounding and oxide removal

This machine is often referred to as the rolei be 5 sheet metal deburring machine or rollei be5 sheet metal deburring machine and is widely praised for its efficiency in large-scale production environments.

Sheet Metal Automatic Deburring Machine: Benefits

Investing in a sheet metal automatic deburring machine offers several advantages for manufacturers:

- Improved Productivity: Automating the deburring process reduces labor costs and increases throughput.

- Higher Quality Finish: Uniform edge rounding and surface cleaning enhance the appearance and performance of parts.

- Enhanced Safety: Smooth edges prevent injuries during handling or assembly.

- Material Versatility: Suitable for steel, aluminum, copper, and other metal sheets or profiles.

Technical Specifications

| Item | Specification |

|---|---|

| Model | R-RB1000 METAL DEBURRING MACHINE |

| Applicable Material | Carbon Steel, Stainless Steel, Aluminum |

| Processing Type | Tube End Deburring, Sheet Edge Deburring, Surface Finishing |

| Tube Deburring Diameter Range | Ø10 mm – Ø120 mm |

| Max Sheet Width | 1300 mm |

| Sheet Thickness Range | 0.5 mm – 20 mm |

| Deburring Method | Rotary Brush + Sanding Belt |

| Conveyor Speed | 0.5 – 5 m/min (Adjustable) |

| Brush Diameter | Ø350 mm (for tube & sheet edge rounding) |

| Brush Material | Abrasive Nylon / Scotch-Brite |

| Belt Grit Options | P80 / P120 / P180 / Customizable |

| Control System | Touchscreen PLC Interface |

| Operation Mode | Fully Automatic / Manual Assist |

| Dust Collection Port | Ø100 mm x 2 (Compatible with industrial vacuum) |

| Power Supply | 380V / 50Hz / 3 Phase (Optional: 220V) |

| Total Installed Power | 8.5 kW |

| Machine Dimensions (L×W×H) | 2200 × 1800 × 1800 mm |

| Weight | Approx. 1800 kg |

| Optional Features | Wet Deburring System, Oxide Removal Head, Double-sided Processing |

| Certifications | CE, ISO9001 |

Conclusion

Whether you need to finish pipes, profiles, or sheets, a reliable metal tube deburring machine or a high-performance Rollei BE5 sheet metal deburring machine can dramatically enhance your production line. These sheet metal automatic deburring machines are indispensable tools for any workshop focused on quality, efficiency, and safety.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao