De juiste ontbraammachine kiezen voor hoogwaardige metalen onderdelen

Deze machines garanderen veiligheid, verbeteren de functionaliteit en verfraaien het uiterlijk van metalen componenten, waardoor ze essentieel zijn in sectoren zoals de auto-industrie, de lucht- en ruimtevaart en de maakindustrie. Dit artikel onderzoekt de soorten ontbraammachines, de voordelen ervan en hoe u de juiste kiest voor uw behoeften.

Inhoudsopgave

Soorten ontbraammachines

Schuurbandontbraammachines

Schuurbandmachines Gebruik roterende schuurbanden om bramen van metalen onderdelen te verwijderen. Ideaal voor productie in grote volumes, ze kunnen diverse metalen verwerken en zorgen voor een consistente afwerking.

Roterende ontbraammachines

Roterende machines gebruiken roterende borstels of wielen om bramen te verwijderen. Ze zijn geschikt voor delicate onderdelen die een fijne afwerking vereisen.

Trommel-ontbraammachines

Trommelmachines gebruiken een trillende trommel en schuurmiddelen om kleine tot middelgrote metalen onderdelen te ontbramen en af te werken. Perfect voor bulkverwerking.

Robotische ontbraamsystemen

Geautomatiseerde robotsystemen zorgen voor nauwkeurig ontbramen van complexe onderdelen. Deze systemen garanderen herhaalbaarheid en zijn geschikt voor precisie-industrieën.

Natte ontbraammachines

Natte ontbraammachines gebruiken schurende materialen in combinatie met koelmiddel om bramen te verwijderen en oververhitting te voorkomen. Ideaal voor warmtegevoelige materialen.

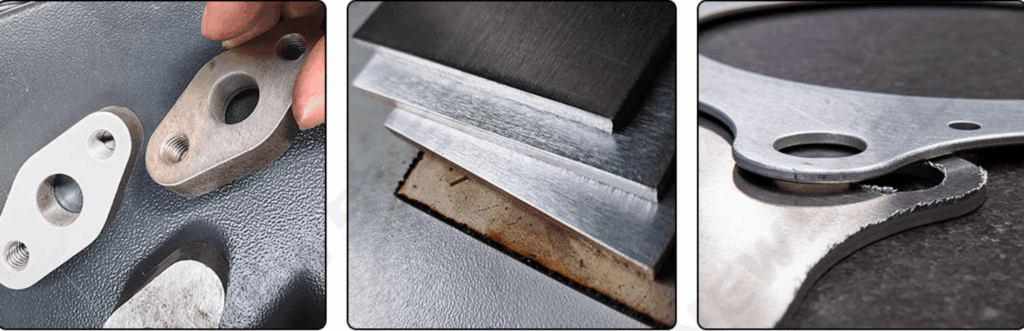

Voordelen van ontbraammachines

Verbeterde veiligheid en efficiëntie

Ontbraammachines Verwijder scherpe randen, verminder het risico op letsel en verhoog de veiligheid van werknemers. Geautomatiseerde systemen verbeteren bovendien de verwerkingssnelheid en -consistentie.

Verbeterde onderdeelkwaliteit

Ontbraammachines verwijderen bramen en onvolkomenheden en zorgen ervoor dat metalen onderdelen goed passen en functioneren. Zo worden problemen tijdens de montage voorkomen.

Verhoogde productiviteit

Geautomatiseerde ontbraamsystemen verlagen de arbeidskosten en verwerkingstijden, waardoor ze ideaal zijn voor de productie van grote volumes.

Kosteneffectief

Door te investeren in een ontbraammachine vermindert u de handmatige arbeid, minimaliseert u herbewerking en verbetert u de productiecapaciteit. Dit leidt tot kostenbesparingen op de lange termijn.

Hoe kiest u de juiste ontbraammachine?

Houd rekening met het type metaal en het volume

Kies de machine op basis van het materiaal waarmee u werkt (bijvoorbeeld aluminium, staal) en het productievolume (kleine batches vs. grootschalige bewerkingen).

Bepaal de gewenste afwerking

Voor een gepolijste afwerking zijn roterende of natte ontbraammachines het beste. Voor snel, grof ontbramen zijn schuurbandmachines efficiënter.

Automatisering versus handmatig

Geautomatiseerde robotsystemen bieden een hogere precisie voor complexe onderdelen, terwijl handmatige machines geschikter zijn voor eenvoudigere taken en kleinere batches.

Conclusie

Ontbraammachines spelen een cruciale rol bij het verbeteren van de kwaliteit, veiligheid en efficiëntie van metalen onderdelen in industrieën zoals de auto-industrie en de lucht- en ruimtevaart. Of u nu een oplossing voor grote volumes nodig hebt of een nauwkeurig ontbraamsysteem voor complexe componenten, de juiste machine selecteren kan de productie stroomlijnen en consistente resultaten garanderen. Investeer in de juiste apparatuur om uw productieproces te verbeteren en superieure afwerkingen te bereiken.

Producten Categorieën

Recent nieuws

Waarom voor ons kiezen

- 16 jaar expertise in de productie van CNC-apparatuur.

- Meer dan 22 jaar ervaring van ons deskundige technische team.

- Vertrouwd in meer dan 100 landen met 800+ installaties wereldwijd.

- 10.000 vierkante meter productiefaciliteit, uitgerust voor grootschalige productie.

- Een toegewijd team van meer dan 20 internationale salesvertegenwoordigers.

- 24/7 ondersteuning met 24/7 after-sales service.

- Een streng kwaliteitsborgingssysteem om producten van topkwaliteit te garanderen.

- Een collaboratieve aanpak het bevorderen van succes voor partners, klanten en personeel.

- Omvattende kant-en-klare oplossingen integratie van productie, service en verkoop.

- Ontworpen om alle soorten metalen werkstukken te hanteren, die tegemoetkomen aan de uiteenlopende behoeften van de industrie.

Neem contact met ons op

- Telefoon: 86-531-88804531

- Telefoon: 86 15562582965

- E-mailadres: [email protected]

- Adres: Wangtai Gongye Industrie, Qingdao