Choosing the Right Metal Polishing Equipment for Superior Finishes

Metal polishing equipment is specifically designed to refine and enhance the appearance of metal surfaces, making them smoother, shinier, and more resistant to corrosion. Whether for automotive parts, jewelry, industrial ma

Inhoudsopgave

What is Metal Polishing Equipment?

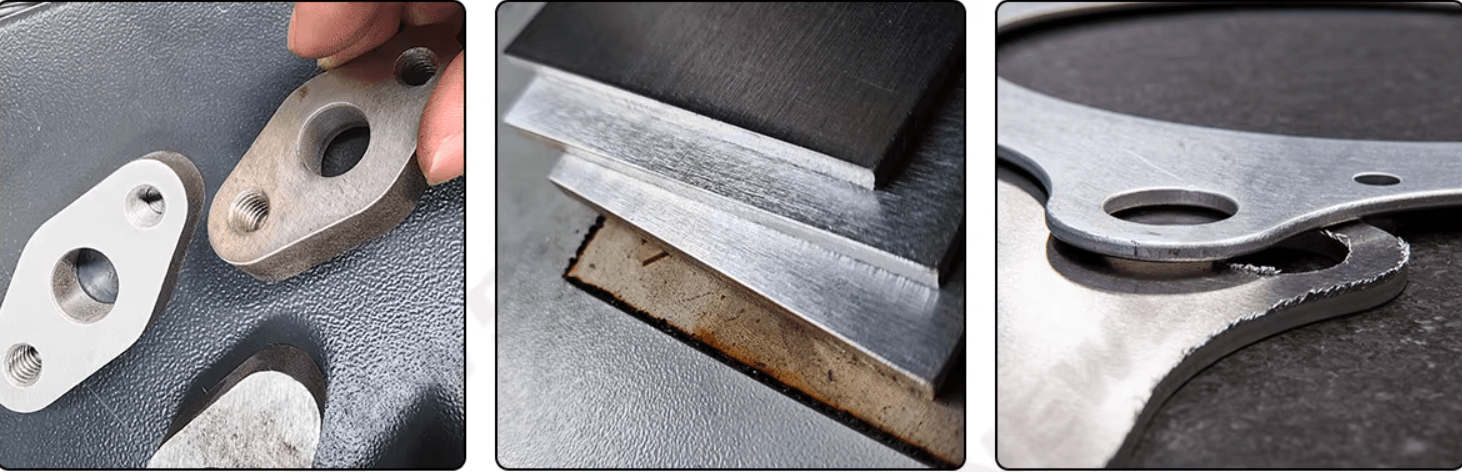

Metal polishing equipment includes a variety of tools and machines used to smooth, refine, and brighten metal surfaces. Polishing machines typically employ abrasives such as polishing wheels, belts, or pads, combined with specific compounds to achieve the desired finish. These machines are widely used in various industries such as automotive, aerospace, manufacturing, and even in artistic applications like jewelry making.

The key function of polishing equipment is to improve the surface quality of metal parts by removing imperfections, oxidation, and scratches, thereby increasing the visual appeal and longevity of the material. Metal polishing is often followed by other finishing processes such as coating, buffing, or sealing to provide additional protection against wear and corrosion.

Types of Metal Polishing Equipment

1. Rotary Polishing Machines

Rotary polishing machines are widely used for polishing flat or curved surfaces. They operate by rotating a polishing wheel at high speed, allowing for the even application of polishing compounds. These machines are suitable for high-volume operations where consistency and efficiency are critical.

Related Keywords:

Rotary polishing systems

Surface finishing machines

2. Belt Polishing Machines

Belt polishing machines use abrasive belts to polish metal surfaces. The belts can be swapped out depending on the desired finish, making them versatile for different applications, from rough polishing to achieving a mirror-like shine. Belt polishing is ideal for processing large flat metal surfaces or cylindrical parts.

Related Keywords:

Abrasive belt sanders

Industrial belt polishing equipment

3. Buffing Machines

Buffing machines use soft, fluffy buffing wheels combined with polishing compounds to bring out the shine on metal surfaces. These machines are best suited for smaller-scale polishing tasks, particularly when a high-gloss finish is required. Buffing machines are commonly used in industries like jewelry making and automotive detailing.

Related Keywords:

Buffing systems

Gloss finish machines

4. Centrifugal Polishing Machines

Centrifugal polishing machines use a high-speed rotating bowl or drum to polish metal parts. These machines are typically used for polishing small, delicate components such as fasteners, small metal pieces, or parts that require intricate finishing. The centrifugal force helps in ensuring uniform polishing.

Related Keywords:

Centrifugal finishing machines

Vibratory finishing systems

5. Vibratory Polishing Machines

Vibratory polishing involves placing parts in a vibrating bowl along with abrasives and polishing compounds. The vibration causes the media to move, polishing the surface of the metal parts. This method is ideal for polishing small to medium-sized parts in bulk.

Related Keywords:

Vibratory deburring machines

Tumbling polishing systems

Benefits of Using Metal Polishing Equipment

1. Verbeterde esthetische aantrekkingskracht

One of the primary reasons metal polishing is essential is the enhancement of visual appearance. Polished metals shine, making them more visually appealing in consumer products, art, or architectural applications. For instance, polished automotive parts or jewelry pieces have a higher value and attractiveness.

2. Verhoogde duurzaamheid

Polishing not only improves the aesthetics of metal but also enhances its durability. A smooth, polished surface is less likely to accumulate dirt, rust, or other contaminants, which helps in maintaining the longevity of the product.

3. Enhanced Performance

Polished metals often experience less friction due to the smoother surface, which can improve the performance of mechanical parts. This is particularly relevant in industries like aerospace, automotive, and manufacturing, where components need to operate smoothly under high stresses.

4. Corrosion Resistance

By removing surface oxidation and applying protective coatings after polishing, metal polishing equipment helps to reduce the risk of corrosion. This is especially important for metals exposed to harsh environmental conditions, such as marine equipment or industrial machinery.

5. Versatility Across Industries

Metal polishing equipment can be customized to meet the needs of various industries, from manufacturing to jewelry making. The ability to polish different types of metals, including stainless steel, aluminum, brass, and copper, makes these machines highly versatile.

Choosing the Right Metal Polishing Equipment

When selecting the right metal polishing equipment for your business, there are several factors to consider:

1. Size and Scale of Operation

Determine whether you require a high-volume, industrial-grade machine or a smaller-scale system for custom or artisanal applications. Larger operations might benefit from automated polishing systems, while smaller operations may prefer manual or semi-automated machines.

2. Type of Metal Being Polished

Different metals require different types of polishing processes. For instance, stainless steel might need a different abrasive compound than aluminum or brass. Ensure that the equipment you choose is suitable for the types of metals you work with.

3. Desired Finish

The level of finish you desire—whether matte, satin, or mirror-like—will dictate the type of polishing equipment you need. Machines designed for heavy-duty deburring and surface preparation are often not ideal for achieving a high-gloss finish.

4. Automation vs. Manual Operation

Consider whether you need automated systems for high-efficiency and consistency or if manual operation is sufficient for smaller batch runs or customized finishing.

Conclusie

Metal polishing equipment plays an essential role in various industries where the aesthetic, performance, and durability of metal products are critical. Whether for industrial manufacturing, automotive detailing, or fine art, polishing machines are designed to refine metal surfaces, improve corrosion resistance, and enhance overall quality.

By choosing the right metal polishing equipment based on factors such as the type of metal, finish requirements, and scale of operation, businesses can significantly enhance the quality of their products and improve their production efficiency. Investing in high-quality polishing equipment ensures that metal components not only meet aesthetic standards but also offer improved performance and longer-lasting durability.

Producten Categorieën

Recent nieuws

Waarom voor ons kiezen

- 16 jaar expertise in de productie van CNC-apparatuur.

- Meer dan 22 jaar ervaring van ons deskundige technische team.

- Vertrouwd in meer dan 100 landen met 800+ installaties wereldwijd.

- 10.000 vierkante meter productiefaciliteit, uitgerust voor grootschalige productie.

- Een toegewijd team van meer dan 20 internationale salesvertegenwoordigers.

- 24/7 ondersteuning met 24/7 after-sales service.

- Een streng kwaliteitsborgingssysteem om producten van topkwaliteit te garanderen.

- Een collaboratieve aanpak het bevorderen van succes voor partners, klanten en personeel.

- Omvattende kant-en-klare oplossingen integratie van productie, service en verkoop.

- Ontworpen om alle soorten metalen werkstukken te hanteren, die tegemoetkomen aan de uiteenlopende behoeften van de industrie.

Neem contact met ons op

- Telefoon: 86-531-88804531

- Telefoon: 86 15562582965

- E-mailadres: [email protected]

- Adres: Wangtai Gongye Industrie, Qingdao