Metal Sheet Brush Surface Finishing Deburring Polishing Machine for Stainless Steel

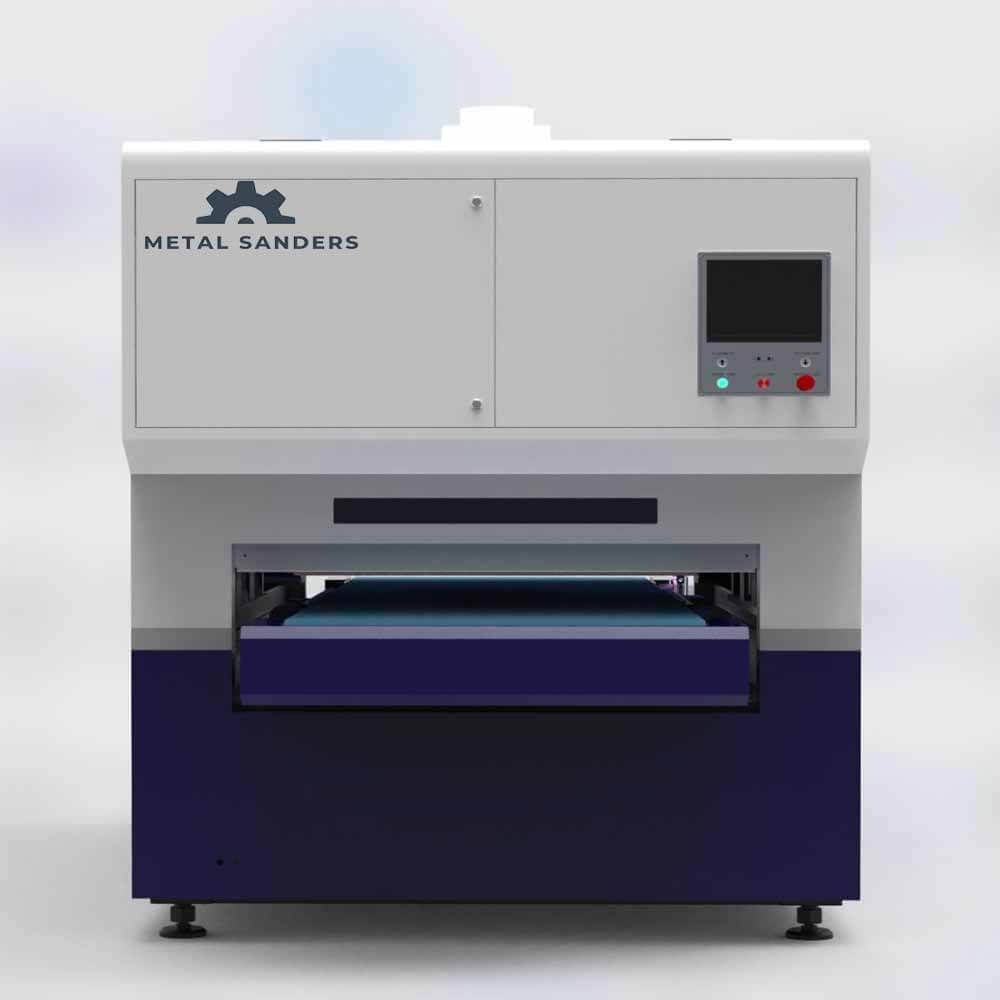

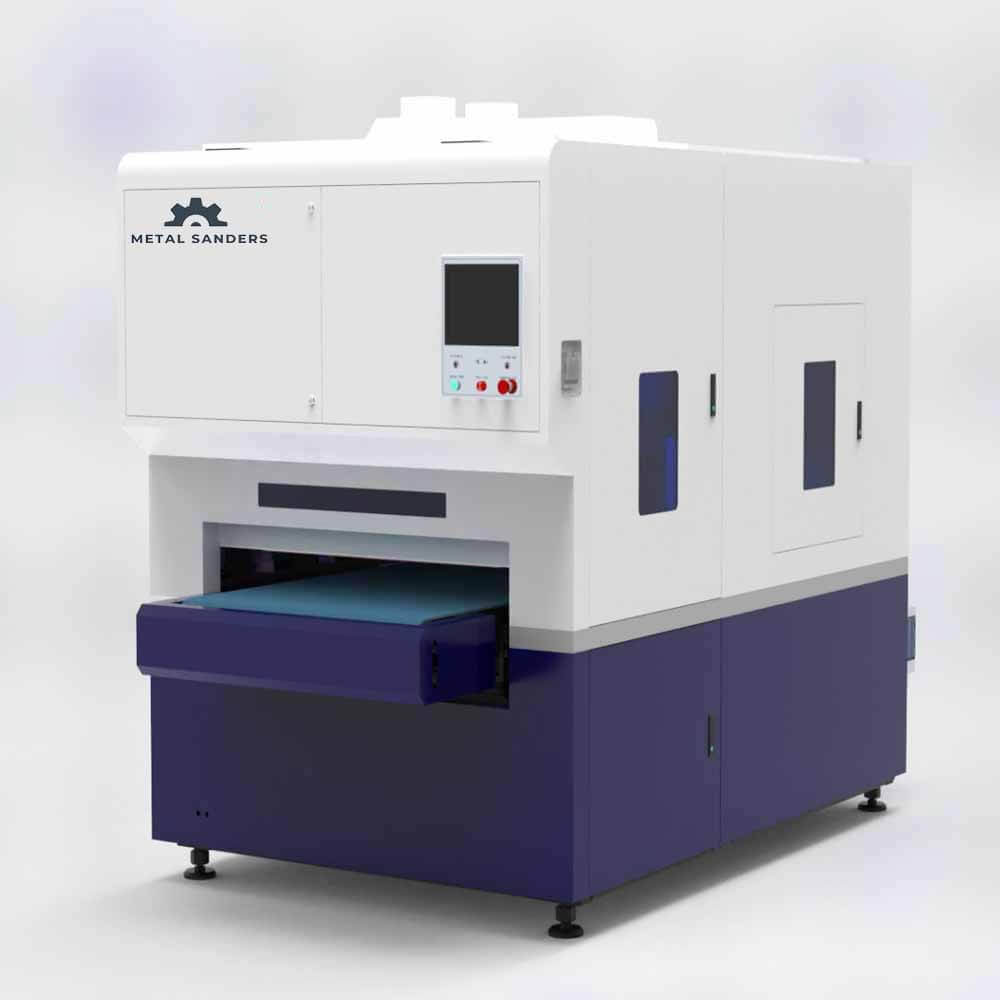

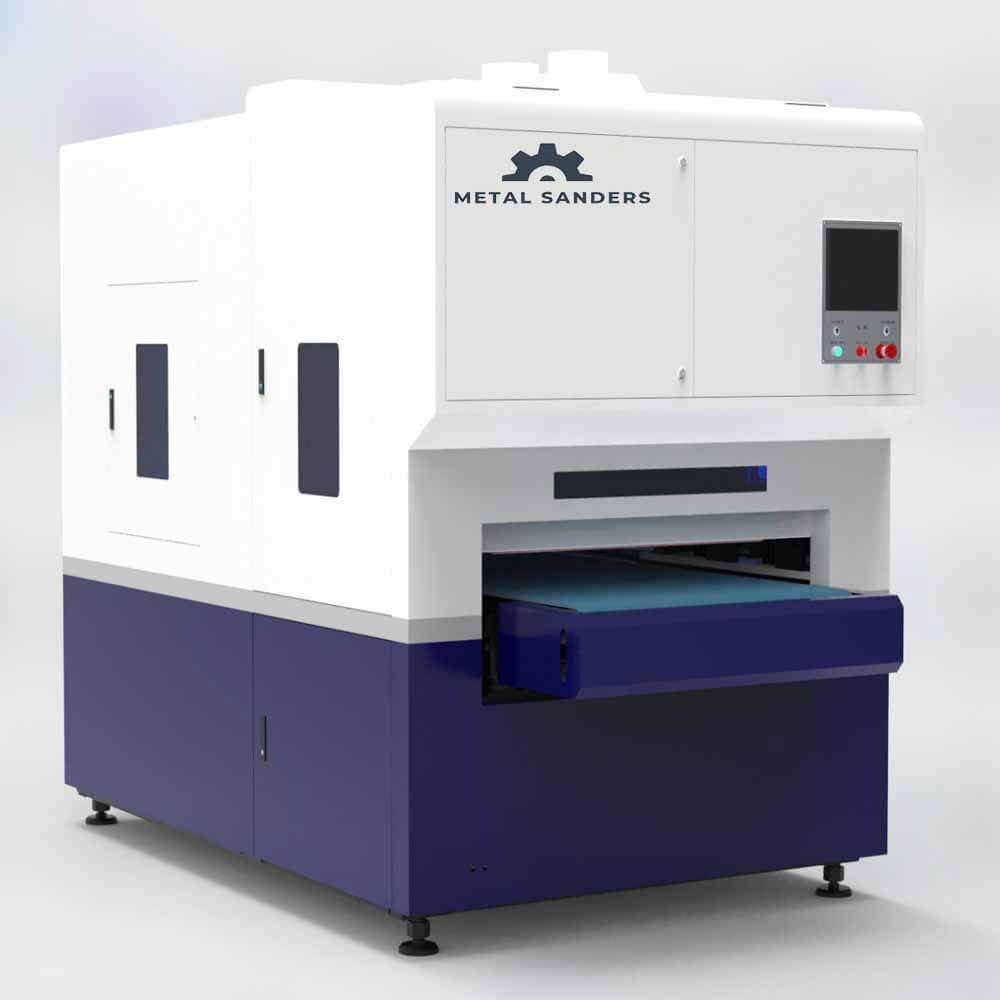

The Metal Sheet Brush Surface Finishing Deburring Polishing Machine for Stainless Steel is a cutting-edge solution designed to provide superior surface finishing and polishing for stainless steel and other metal sheets. This machine combines advanced brush and abrasive technologies, ensuring high-quality deburring, polishing, and surface preparation.

Table of Contents

What is a Metal Brush Sander Machine?

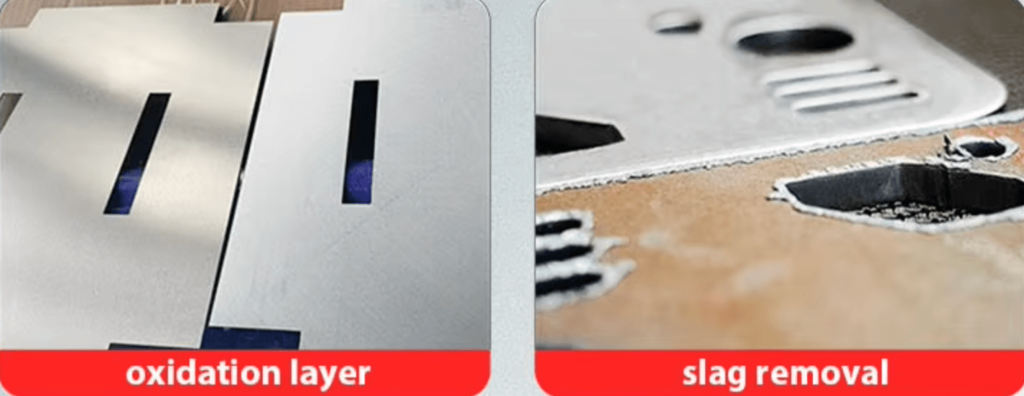

A Metal Brush Sander Machine is an advanced tool designed for surface finishing, deburring, and polishing metal sheets. It uses rotating brushes or abrasive belts to remove imperfections such as burrs, rust, oxidation, and scratches from the surface of the metal. The use of specialized brushes allows for gentle yet effective polishing, making it an ideal choice for stainless steel and other metals that require a smooth, high-quality finish.

By integrating the Metal Brush Sander Machine into your production line, manufacturers can significantly improve the surface quality of metal parts and sheets. This machine is highly effective for preparing metal for further processing or for producing finished components with an enhanced appearance.

How the Metal Sheet Brush Surface Finishing Deburring Polishing Machine Works

The Metal Sheet Brush Surface Finishing Deburring Polishing Machine for Stainless Steel utilizes a combination of abrasive brush systems and polishing belts to remove burrs, oxidation, and surface imperfections from stainless steel and other metal sheets. The process starts with the abrasive belt, which smooths out rough surfaces and removes heavy burrs. The finishing stage is carried out with the brushing system, which provides a polished, satin, or brushed finish based on the specific requirements.

This dual system ensures that the metal sheet is not only deburred but also given a professional finish, enhancing its visual appeal and preparing it for further manufacturing processes. The versatility of the machine allows for customization of the finishing process to meet industry standards for various applications.

Benefits of Sheet Metal Brushing and Polishing Machines

The Sheet Metal Brushing Machine Polishing Machine offers numerous benefits that make it an essential tool for metal surface treatment. Some of the key advantages include:

High Efficiency: The machine is designed to process large volumes of metal parts quickly, improving overall productivity. Its automated features reduce the need for manual labor, saving time and effort.

Superior Surface Finish: Whether you’re looking to create a brushed, satin, or polished finish, this machine delivers consistent and high-quality results every time.

Versatility: Capable of handling different metal materials, the Sheet Metal Brushing Machine Polishing Machine is adaptable to a variety of industries, from construction to electronics.

Cost-Effective: The combination of abrasive belts and brush systems allows for efficient material removal, reducing the cost of consumables and improving operational efficiency.

Environmental Friendliness: The machine’s efficient use of abrasive belts and low energy consumption helps minimize waste and supports sustainable manufacturing practices.

Conclusion

The Metal Sheet Brush Surface Finishing Deburring Polishing Machine for Stainless Steel is an indispensable tool for industries requiring high-quality metal surface treatments. Combining the benefits of a Metal Brush Sander Machine, Electric Abrasive Belt Finishing Machine, and Sheet Metal Brushing Machine Polishing Machine, this machine provides a reliable, efficient, and cost-effective solution for deburring, polishing, and finishing metal sheets.

By investing in this advanced technology, businesses can enhance product quality, improve production efficiency, and meet the high standards demanded in industries like automotive, aerospace, and general manufacturing. This machine not only ensures superior surface finishes but also supports sustainable and environmentally responsible manufacturing processes.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao