Metal Sanding: Key to Enhancing Laser Cut Surface Quality

However, despite its advantages, laser-cut metal parts often exhibit surface imperfections such as burrs, oxidation layers, and uneven textures, which can compromise the appearance and functionality of the final product. This is where metal sanding comes into play as an indispensable step in achieving the best surface quality for laser-cut parts.

Table of Contents

The Challenges of Laser Cut Parts

Burr Removal: Laser cutting generates high heat, causing the material edges to form small, sharp burrs. These burrs must be removed to avoid affecting the part’s assembly accuracy and to ensure safety during handling.

Oxidation Layer: The intense heat during laser cutting can cause oxidation, which forms a layer of discoloration on the surface. Not only does this reduce the aesthetic quality of the material, but it can also impact the adhesion of coatings and interfere with welding processes.

Uneven Texture: The surface of laser-cut parts must often meet specific smoothness standards to meet industry requirements and satisfy customer expectations. Uneven textures or rough edges can detract from the product’s overall quality.

The Importance of Sanding in Surface Treatment

Efficient Burr Removal: Sanding removes burrs effectively, smoothing out the edges and making the parts safer to handle and assemble. This improves the overall functionality of the part and ensures a clean finish.

Eliminating Oxidation: Sanding is effective in removing oxidation layers, revealing the metal’s natural shine. This is crucial for improving the appearance of the part and ensuring a clean surface for subsequent processes like coating or welding.

Enhancing Surface Uniformity: Sanding provides a smooth, even surface, enhancing the visual appeal of the product. A more uniform surface also ensures better performance in downstream operations like painting, plating, or assembly.

Choosing the Right Sanding Equipment

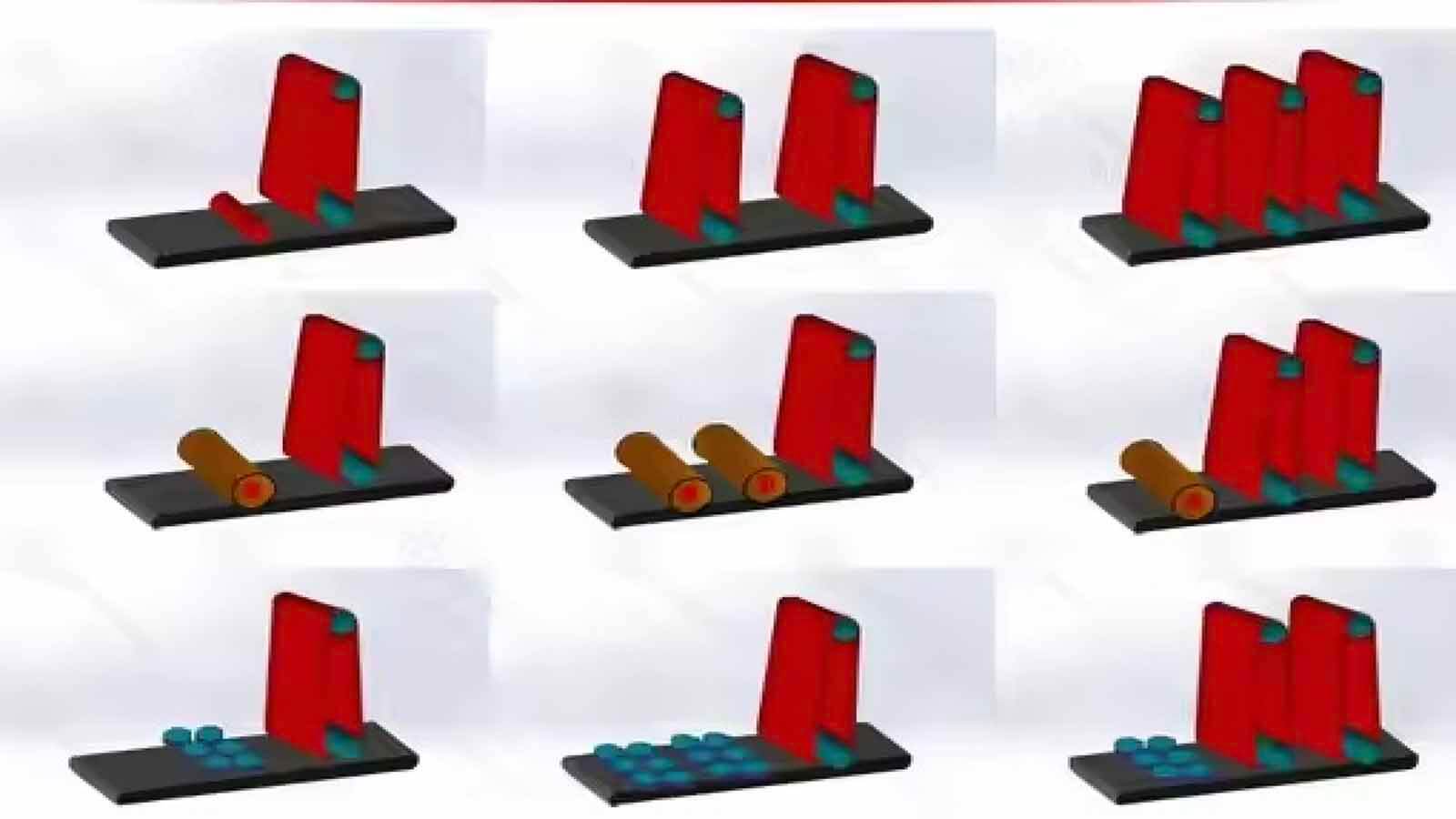

Selecting Based on Part Size: For large, flat metal sheets, wide-belt sanders are ideal. For more intricate, precision parts, handheld or tabletop sanders offer more control for detailed work.

Focusing on Performance: High-performance sanding equipment ensures stable operation and efficient processing speeds, making it suitable for high-volume production needs.

Environmental and Energy Efficiency: Advanced sanding equipment typically includes efficient dust removal systems that minimize environmental impact and conserve energy.

After-Sales Support: Excellent after-sales service is crucial for maintaining equipment longevity and minimizing downtime, ensuring the continuity of operations.

Conclusion

Metal sanding is an essential step in perfecting the surface quality of laser-cut parts. By effectively removing burrs, oxidation layers, and texture inconsistencies, sanding enhances both the appearance and functionality of the final product. As the demand for high-quality metal products increases, sanding is becoming an indispensable part of the laser cutting process. By selecting the right sanding equipment and optimizing the sanding process, businesses can significantly improve the quality of their laser-cut parts and gain a competitive advantage in the marketplace.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao