Metal Sanding: Choosing the Right Machine for Optimal Results

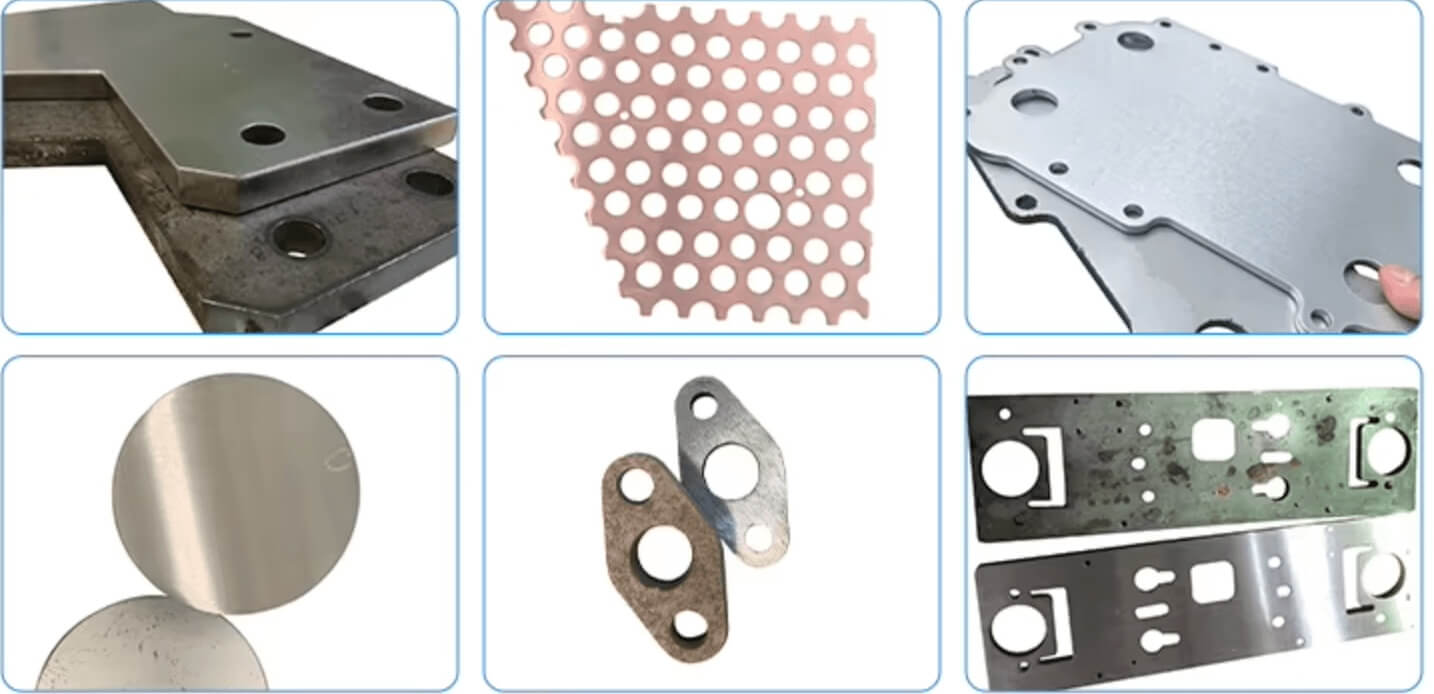

Different metals have unique characteristics and respond differently to the sanding process, so it’s essential to choose the right machine to achieve the desired finish. Sanding is commonly used in the intermediate stages of metal processing, preparing surfaces for further treatments. It smoothens the metal, removes imperfections, and enhances both the functional and aesthetic qualities of the material. The result is a consistent, refined surface with a semi-gloss or matte finish, and varying levels of roughness, depending on the industrial needs.

Table of Contents

Selecting the Ideal Metal Sanding Machine

To achieve the best sanding results, it’s important to match the machine with the type of metal being processed. The right metal sander can make all the difference, whether you’re working with delicate materials like aluminum or more robust metals such as brass and steel. Depending on the metal, the sanding process can alter the surface roughness, remove scratches, and ensure smoothness for subsequent treatments, such as coating, welding, or polishing.

When sanding different types of metals, using the proper equipment tailored for each material is key. For instance, machines that can effectively handle soft metals like brass without leaving marks or damaging the surface are essential. Additionally, if you’re working with a combination of metals in one project, such as brass and nickel, a versatile sanding machine with easy adjustments for different materials will save time and enhance efficiency.

Types of Metal Sanding Machines

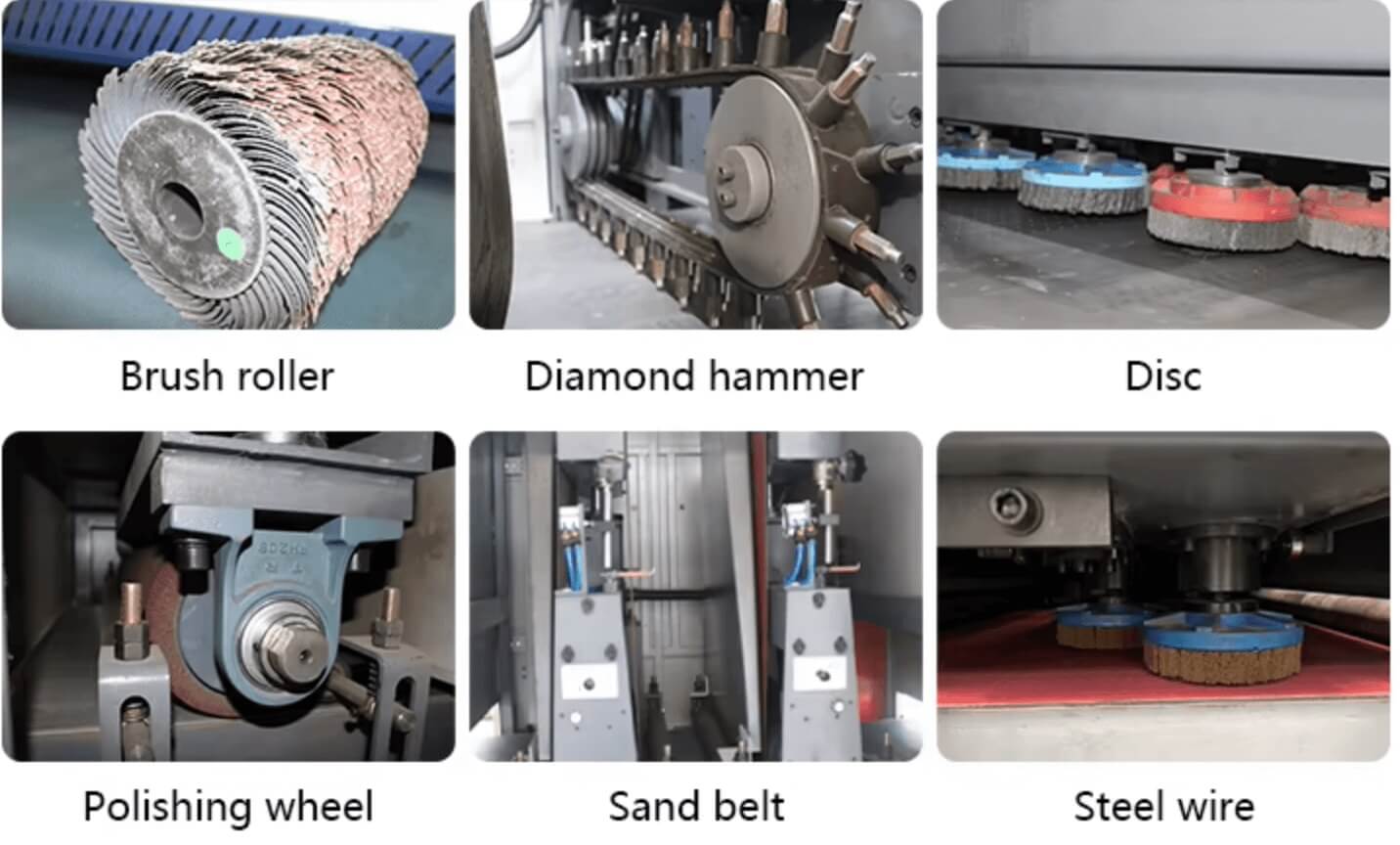

Metal sanders are engineered with cutting-edge technology to provide high precision and superior results. These machines cater to a wide range of industrial applications, whether for small workshops or large-scale production environments. From artisans and small manufacturers to medium-sized businesses and large factories, metal sanding machines offer tailored solutions to improve product quality, streamline production, and boost efficiency.

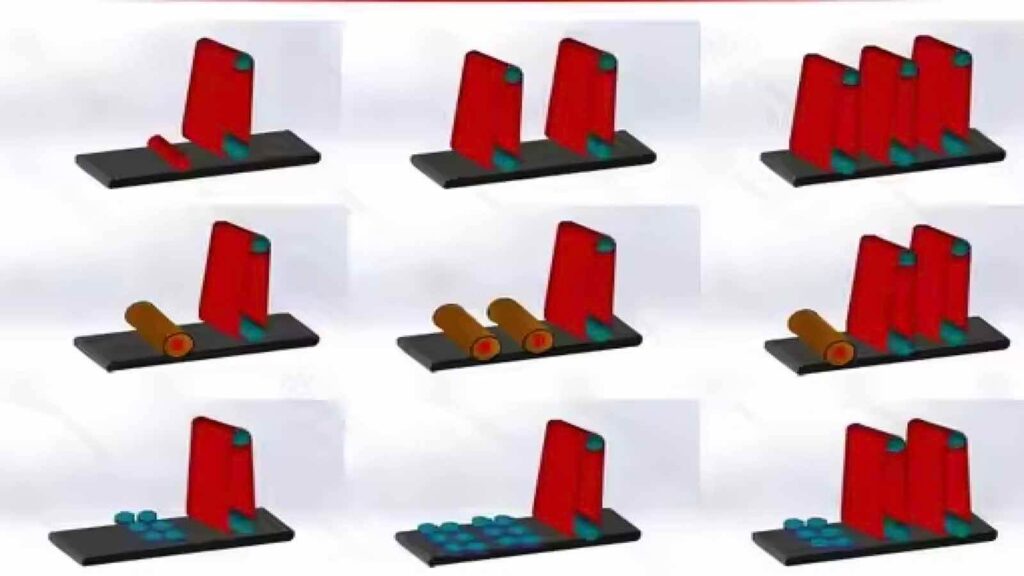

The versatility of modern metal sanding machines is one of their standout features. With customizable configurations, users can adjust abrasive belts, wheels, and cutters to meet specific project requirements. Whether you’re looking to refine metal surfaces, deburr edges, or prepare materials for coatings, these machines can do it all. Additionally, complete sanding and finishing systems are available, allowing businesses to process a variety of materials simultaneously, increasing throughput.

Customization for Specific Needs

In addition to standard sanding solutions, many manufacturers offer bespoke metal sander designs to cater to the unique needs of individual businesses. Whether you require a machine that can handle high production volumes or a specialized design for a specific material, a custom solution is often the best choice. Companies that offer custom machines can also provide testing with your own materials to ensure the machine meets performance expectations before it’s delivered.

Conclusion

Choosing the right metal sander is essential for achieving quality results in metalworking projects. Whether you’re a small workshop or a large industrial facility, investing in the right machine for the job will improve both the efficiency and quality of your sanding process. With versatile options, customization capabilities, and the ability to handle a wide range of materials, metal sanders are an indispensable tool for any metalworking operation, ensuring consistent, professional results with every project.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao