Metal Sanders Machines Important for Laser Cutting Workpieces

These machines play a pivotal role in post-processing laser-cut parts, ensuring superior surface finishes and overall product quality.

Table of Contents

The Need for Sanding

Fiber laser cutting, while precise, often leaves behind burrs, heat-affected zones, and oxide layers on the cut edges. These imperfections can compromise the functionality and aesthetics of the final product. Metal sanding effectively addresses these issues by:

- Removing burrs: Sharp edges and burrs are eliminated, improving part safety and reducing the risk of injuries during handling.

- Cleaning surfaces: Removing oxides, scale, and other contaminants to prepare surfaces for subsequent processes such as painting, coating, or welding.

- Improving surface finish: Providing a smooth and consistent surface finish, enhancing the appearance of the finished product.

- Enhancing adhesion: Creating a micro-rough surface that promotes better adhesion of coatings and adhesives.

How Sanding Works

Metal sanding involves propelling abrasive media, such as sand, glass beads, or metal shot, at high velocity onto the workpiece surface. The impact of the abrasive particles removes surface material, creating a desired finish.

Applications of Sanding in Fiber Laser Cutting

- Stainless Steel: Removing oxides and improving the corrosion resistance of stainless steel components.

- Automotive Parts: Preparing surfaces for painting and improving the appearance of automotive body panels.

- Aerospace Components: Achieving precise surface finishes and removing burrs from critical aerospace parts.

- Mold Making: Creating smooth and precise mold surfaces for high-quality castings.

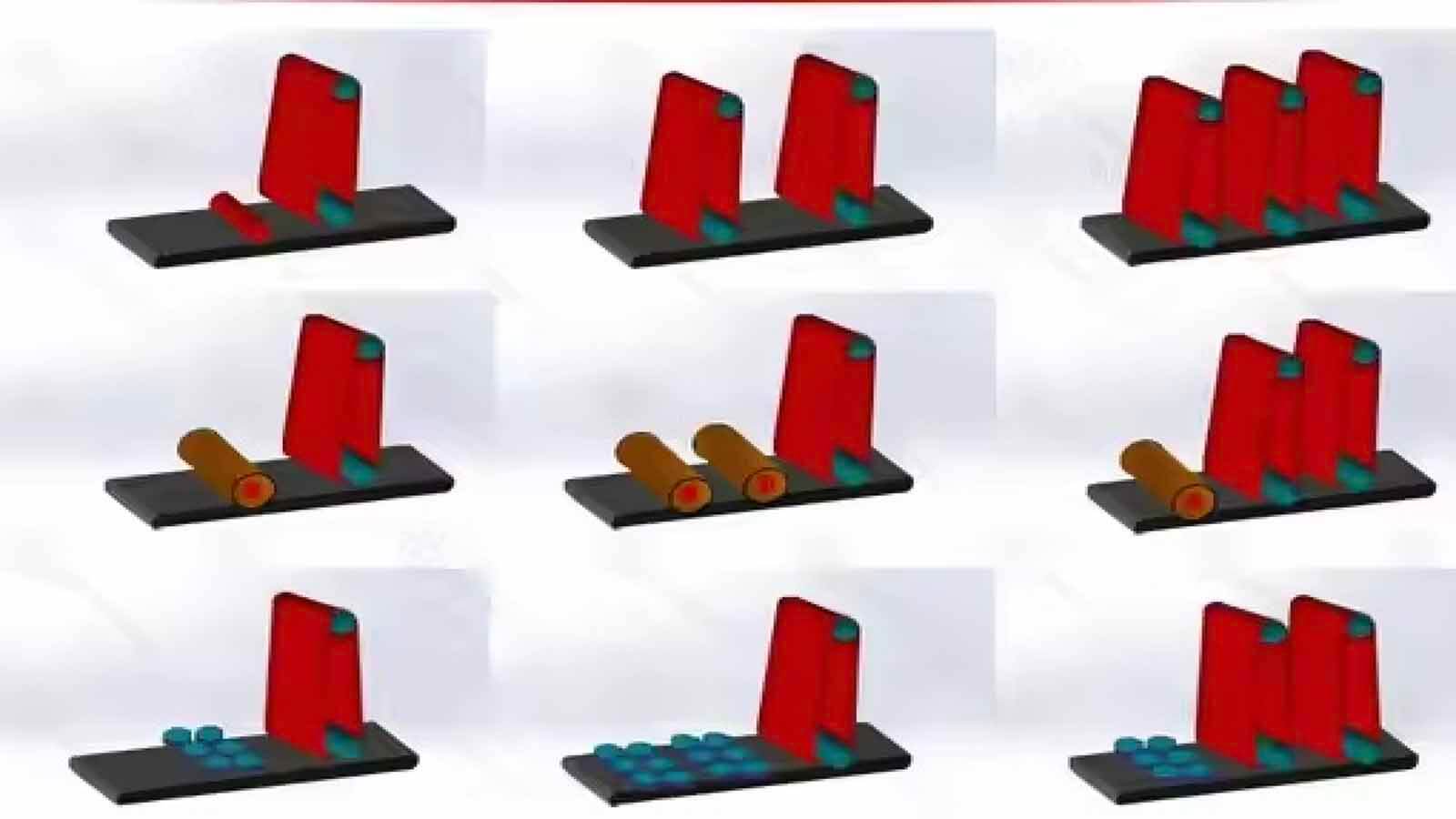

Types of Sanding Machines

- Dry Sanding: Uses compressed air to propel abrasive media onto the workpiece.

- Wet Sanding: Employs a water-based slurry of abrasive media, providing a cleaner and more controlled process.

- Robot Sanding: Offers high precision and repeatability for complex part geometries.

Conclusion

Metal sanding has become an integral part of the metal fabrication process, complementing the capabilities of fiber laser cutting machines. By addressing surface imperfections and enhancing the overall quality of parts, sanding plays a vital role in meeting the demanding requirements of modern manufacturing.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao