Metal Sanders Machine: Choosing the Right Tool for the Job

However, selecting the right metal sander machine can be challenging, especially when working on new projects or unfamiliar applications. Safety and efficiency are key when working with abrasives to remove material. The ideal machine for your shop will depend on the size of your workpiece, the volume of material to be removed, and the desired processing speed.

Table of Contents

Wide Belt Sanders

Wide belt sanders are designed for high-volume operations and are ideal for processing large metal sheets or plates. These machines, available in widths ranging from 25” to 52”, utilize sanding belts to refine the top surface of the material. Equipped with a conveyor system, they guide the workpiece through the machine, where a drum and sanding belt ensure consistent sanding. Many models feature oscillating drums to deliver an even finish and minimize surface scratches.

Applications of Wide Belt Sanders:

Deburring large, flat metal pieces

Removing slag and dross after plasma cutting

Adjusting material thickness slightly

Preparing surfaces for welding or finishing

Surface Grinders

Surface grinders are renowned for their precision and versatility. Operating with three-axis movement—two for the table and one for the cutting arm—they offer exceptional control for detailed work. Available in manual or CNC configurations, surface grinders are essential for precise machining tasks.

Common Uses for Surface Grinders:

- Reducing material thickness efficiently

- Crafting tooling such as punches and dies

- Sharpening and repairing tools

- Precision grooving, shaping, and squaring

- Producing smooth, finished surfaces

Industrial Belt Sanders

Industrial belt sanders are versatile machines, ranging from 1 HP to 20 HP, with belt widths up to 14”. These machines are often configured in vertical or horizontal orientations and are essential for heavy-duty sanding. Wet belt sanders are an excellent option for reducing airborne dust and preventing excessive heating of the workpiece.

Benefits of Industrial Belt Sanders:

- Freehand shaping and sanding of edges

- Deburring small to medium components

- Smoothing sharp corners

- High-volume sanding tasks

- Surface finishing and buffing

Note: Belt sanders are not suitable for removing large amounts of material. For heavy-duty removal, consider grinders, saws, or plasma cutting tools.

Belt Grinders and Bench Grinders

Belt grinders, similar to belt sanders, use tougher abrasives such as aluminum oxide, silicon carbide, or ceramic. They are commonly found as benchtop machines but also come in handheld models. Bench grinders are often paired with belt grinders, combining the two functionalities into a single machine for added versatility.

Key Uses for Belt and Bench Grinders:

- Grinding curved or concave surfaces

- Refining small components

- Sharpening tools and blades

- Rapid material removal

- Deburring and edge finishing

Brush Sanders

Brush sanders function like wide belt sanders but use brushes instead of abrasive belts. These brushes can be easily interchanged to suit different material types, making them highly adaptable.

Applications of Brush Sanders:

- Polishing and refining surfaces

- Creating directional graining patterns

- Removing minor defects or oxidation

- Light deburring tasks

Specialized Sanding and Grinding Machines

For niche applications, specialized metal sander machines are available. These tools are tailored to specific tasks, offering unmatched efficiency in their designated roles.

Examples of Specialized Machines:

- Weld Shavers: Perfect for grinding weld beads flush with the material, ensuring a smooth finish. Available for flat and angled welds.

- Bevel Mills and Shape Bevelers: Ideal for deburring and beveling straight edges, interior curves, and pipe interiors with precision.

Choosing the Right Metal Sanders Machine

The key to selecting the best metal sander machine lies in understanding your specific requirements, including material type, workpiece size, and desired finish. From wide belt sanders for flat surfaces to belt grinders for small components, each machine type offers unique advantages to meet your metalworking needs. With the right equipment, you can streamline operations, improve efficiency, and achieve exceptional results.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

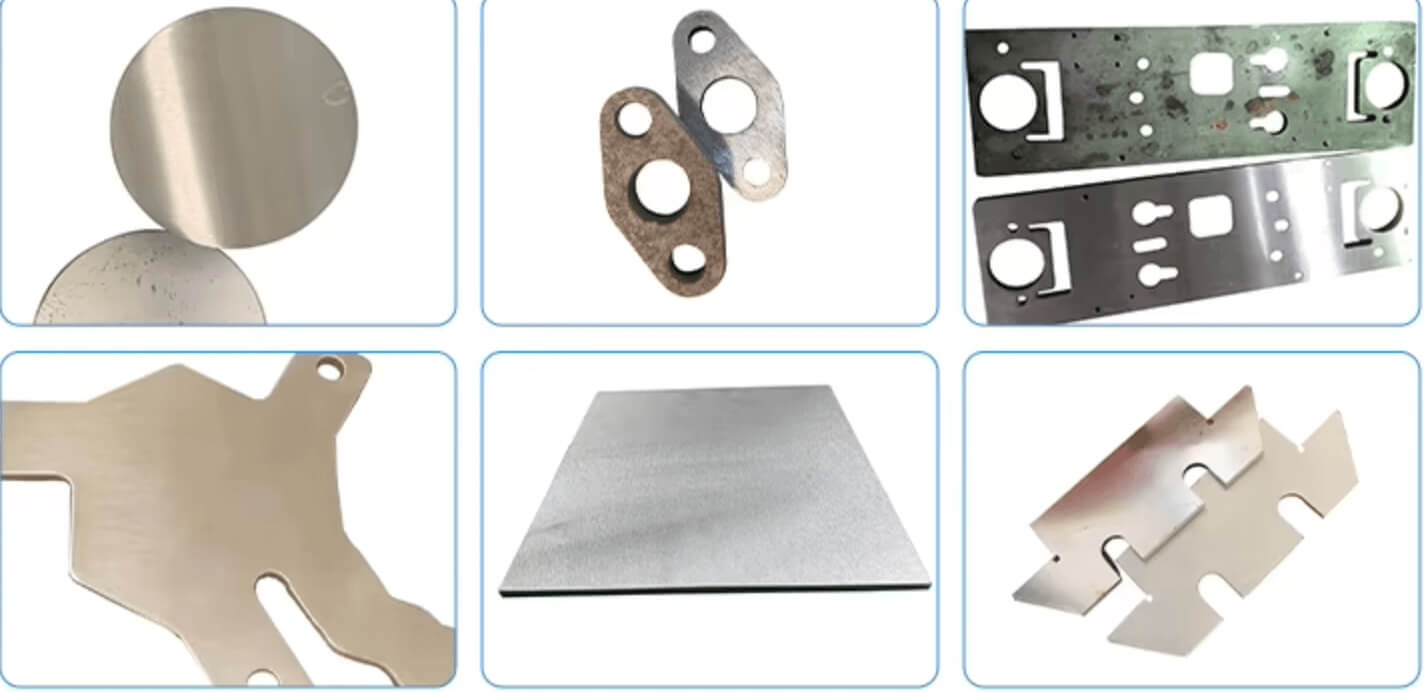

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao