Metal Sanders: Best Surface Treatment for Steel, Iron, Aluminum

Using metal sanders (also known as metal grinding machines, metal polishing machines, or metal surface finishing equipment), you can easily achieve smooth and visually appealing metal surfaces. This article explores surface treatment methods for stainless steel, iron, aluminum, and brass and how to choose the right metal sanding equipment to optimize your work efficiency.

Table of Contents

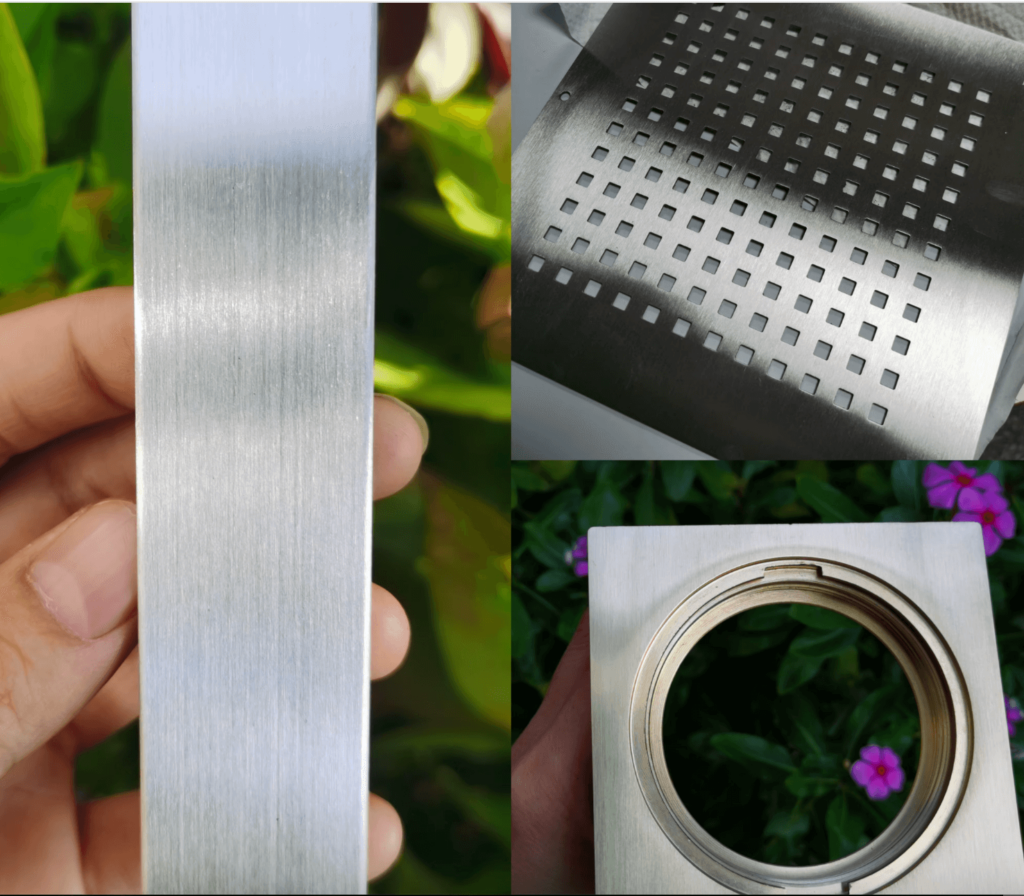

Surface Treatment Methods for Stainless Steel

Characteristics of Stainless Steel

Stainless steel is known for its corrosion resistance and high strength, but its surface treatment requires extra care to avoid scratches and uneven finishes.

Treatment Methods

- Deburring: Use a belt sander or wide-belt sander to remove burrs from stainless steel sheets or tubes.

- Uniform Sanding: With the help of a cylindrical sander (also referred to as a stainless steel tube grinder), you can achieve consistent surface smoothness.

- Mirror Polishing: Specialized polishing belt sanders can create a high-gloss mirror finish.

Tips

It is recommended to use industrial-grade metal sanding machines designed specifically for stainless steel to prevent scratches or overheating that may cause discoloration.

Surface Treatment Methods for Iron

Characteristics of Iron

Iron surfaces are prone to rust, making smoothness and pre-coating preparation especially important during processing.

Treatment Methods

- Rough Grinding: Use an industrial belt grinder to remove scale and surface impurities.

- Fine Sanding: A flat surface sander or double-head belt sander improves surface smoothness for subsequent coating applications.

- Anti-Rust Coating: Immediately apply anti-rust paint after sanding to extend the product’s lifespan.

Tips

Avoid excessive grinding on iron surfaces to maintain strength. Choose sanding belts suitable for iron materials.

Surface Treatment Methods for Aluminum

Characteristics of Aluminum

Aluminum is lightweight and has excellent thermal conductivity, but it is softer and more prone to scratches.

Treatment Methods

- Initial Sanding: Use a high-speed metal sander or aluminum-specific grinder to remove burrs and oxide layers.

- Fine Finishing: A vibrating sander (ideal for thin aluminum sheets) can achieve a delicate matte finish.

- Oxidation Treatment: Post-sanding, aluminum is often anodized to enhance corrosion resistance and aesthetics.

Tips

Use sanding belts or discs designed for soft metals like aluminum to avoid over-sanding or scratches.

Surface Treatment Methods for Brass

Characteristics of Brass

Brass is visually appealing and often used for decorative components but is susceptible to oxidation and discoloration.

Treatment Methods

- Cleaning and Deoxidizing: Use a rotary sander (also called a disc grinder) to effectively remove oxidation from brass surfaces.

- High-Gloss Polishing: Achieve a shiny finish using a metal polishing machine.

- Protective Coating: Apply a transparent protective lacquer after polishing to prevent oxidation.

Tips

Choose softer sander attachments to avoid damaging the brass surface.

Choosing the Right Metal Sander

Different metals require specific sanding equipment. Below are some common metal surface finishing machines to consider:

- Flat Surface Sanders

- Industrial Belt Grinders

- Stainless Steel-Specific Sanders

- Vibrating Sanding Machines

- Automatic Metal Polishers

Pro Tip: For workshops needing versatile solutions, consider a multi-functional metal sander with adjustable speeds and interchangeable heads to handle a wide range of applications.

Conclusion

Whether for industrial production or small-scale processing, selecting the right metal sanding machine (such as a metal grinder, metal polishing machine, or metal surface finishing equipment) is key to enhancing work efficiency and product quality. Using the methods outlined above, you can achieve effective surface treatment tailored to each metal type.

If you’re looking for professional metal sanding equipment, we offer a wide range of models suitable for surface treatment of stainless steel, iron, aluminum, brass, and more. Feel free to contact us for more details!

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao