Metal Sander Machine for Sheet Metal Sanding and Surface Finishing

Whether you’re in the business of manufacturing, fabrication, or industrial production, achieving a smooth and consistent finish on your workpieces is critical. That’s where a high-quality surface finishing machine comes into play.

Table of Contents

What Is a Metal Sander Machine?

A metal sander machine is specifically designed to sand, grind, and polish metal surfaces such as steel, aluminum, copper, and brass. These machines are used to remove scratches, rust, burrs, and oxidation from sheet metal surfaces. They provide a consistent, clean, and professional finish — critical for both aesthetic and functional purposes.

Applications of Sheet Metal Sanding

Sheet metal sanding is required in various industries including automotive, aerospace, appliance manufacturing, and stainless steel product fabrication. A wide belt sander or flat plate grinder is often used for this purpose. These machines handle large surface areas and deliver uniform finishes, making them ideal for sanding panels, plates, and large-scale parts.

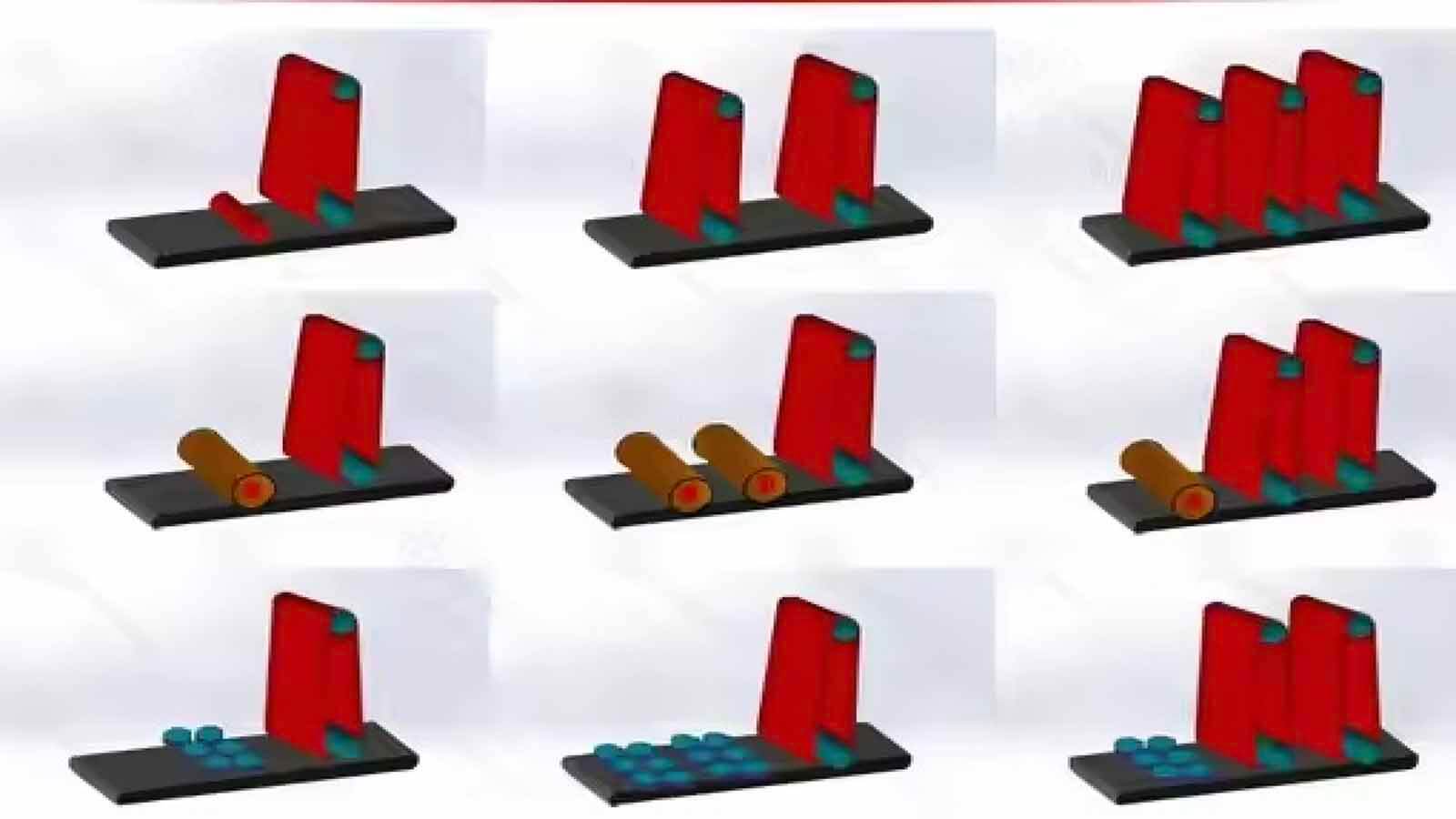

Deburring and Edge Rounding

After cutting or punching sheet metal, sharp edges and burrs are left behind, posing safety hazards and interfering with further processing. This is where deburring equipment becomes crucial. These machines efficiently round edges, clean up profiles, and improve the bonding surface for painting or welding.

Choosing the Right Surface Finishing Machine

When selecting a surface finishing machine, consider factors such as material type, desired finish, production volume, and automation needs. For high-volume operations, an industrial polisher or wide belt sander with multiple abrasive stations can deliver fast and consistent results. For more precise jobs, a flat plate grinder offers greater control.

Why Invest in Quality Metalworking Equipment?

Durable and efficient metalworking equipment increases productivity, reduces rework, and ensures a higher standard of quality. It also minimizes operator fatigue and enhances workplace safety. Modern metal sander machines are equipped with dust collection systems, digital controls, and automatic thickness detection to streamline operations and reduce manual errors.

RR-1300 Metal Sander Machine Specification Table

| Item | Specification |

|---|---|

| Model | RR-1300 |

| Working Width | 1300 mm |

| Working Thickness | 0.5 – 100 mm |

| Abrasive Belt Size | 1330 × 2200 mm |

| Main Motor Power | 30 kW (Optional: 37 kW) |

| Feeding Speed | 5–30 m/min (Variable Frequency Drive) |

| Feeding Motor Power | 2.2 kW |

| Lifting Motor Power | 0.55 kW |

| Dust Collection Ports | 3 × Ø150 mm |

| Machine Dimensions | 2500 × 2200 × 2100 mm |

| Net Weight | Approx. 3500 kg |

| Functions | Deburring, deslagging, oxide film removal, surface polishing |

| Suitable Materials | Stainless steel, carbon steel, aluminum, copper plates |

| Control Panel | Touchscreen with digital thickness display |

| Belt Tension System | Pneumatic belt tensioning |

| Conveyor Table | Rubber-coated, heavy-duty industrial belt |

| Optional Features | Magnetic table, wet sanding system, vacuum hold-down |

Conclusion

From sheet metal sanding to deburring and surface polishing, the right metal sander machine can dramatically improve your finishing process. Investing in advanced surface finishing machines, industrial polishers, and wide belt sanders ensures your metal parts are clean, safe, and ready for the next step in production.

Upgrade your fabrication line today with reliable deburring equipment and metalworking solutions designed for industrial excellence.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao