Metal Profile Deburring Blunting Machine: Precision Finishing for Metal Profiles

Our advanced metal profile deburring machines combine precision technology with user-friendly operation, providing consistent edge blunting and surface finishing for a wide range of metal profiles including steel, aluminum, and stainless steel.

Table of Contents

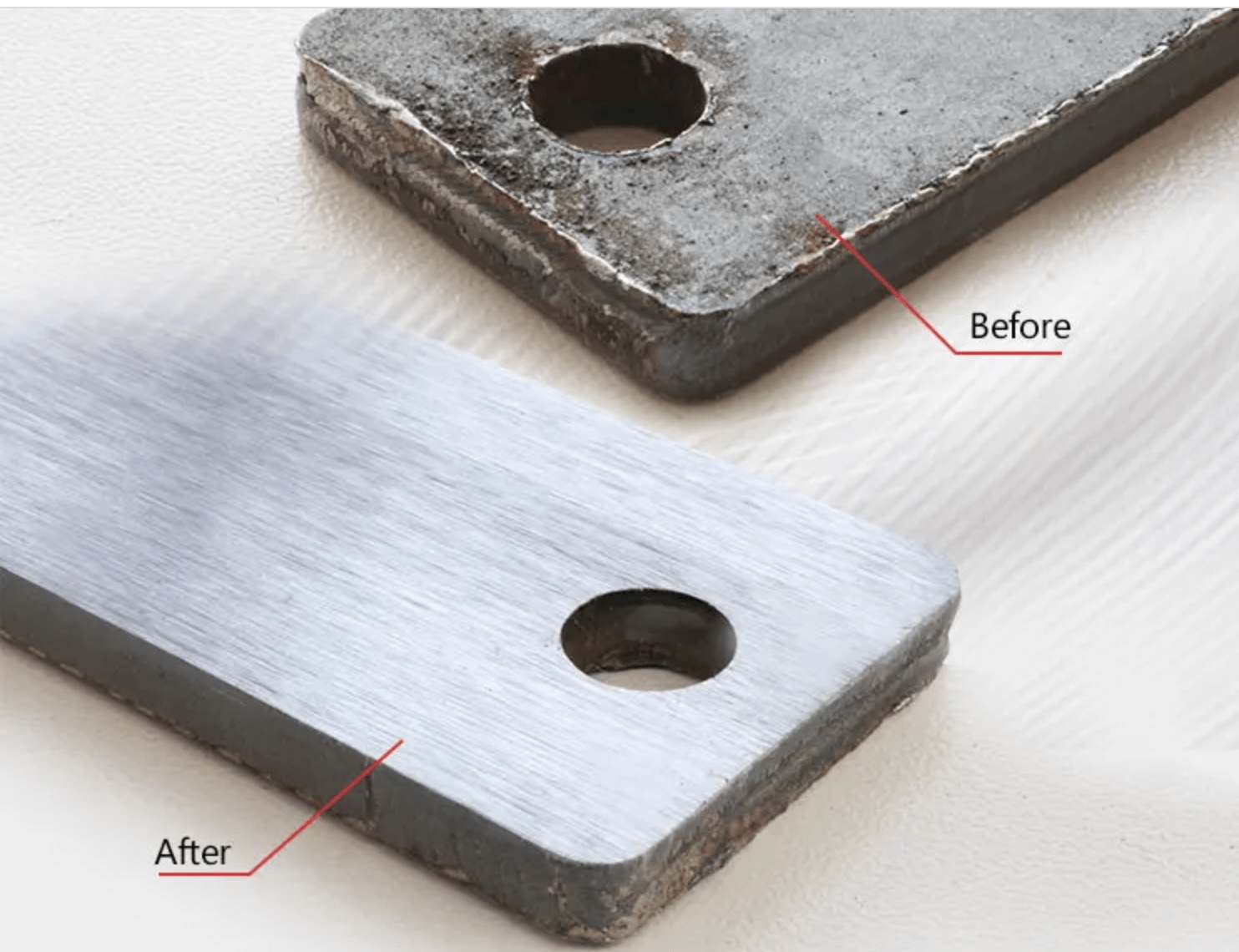

Why Choose a Metal Profile Deburring Machine?

- Safety Enhancement: Removes sharp edges and burrs that could cause injury during handling or assembly.

- Improved Aesthetics: Produces clean and uniform edges, improving the visual appeal of metal products.

- Surface Preparation: Prepares metal surfaces for painting, coating, or welding by removing oxidation and irregularities.

- Efficiency: Automates the deburring and blunting process, reducing manual labor and production time.

- Versatility: Suitable for various metal profiles such as angles, channels, tubes, and custom extrusions.

The Role of Metal Rolling Brush Deburring Machines

A key component in modern deburring technology is the metal rolling brush deburring machine. This machine uses rotating abrasive brushes to gently remove burrs and round off edges on metal profiles. The rolling brush action is especially effective at reaching irregular surfaces and complex geometries that other deburring methods might miss.

Benefits include:

- Consistent edge rounding without damaging the profile’s dimensions.

- Removal of oxide layers and surface contaminants.

- Longer brush life compared to abrasive belts.

- Dry operation reduces maintenance and cleanup efforts.

Metal Sanding Brush Deburring Machines for Superior Finish

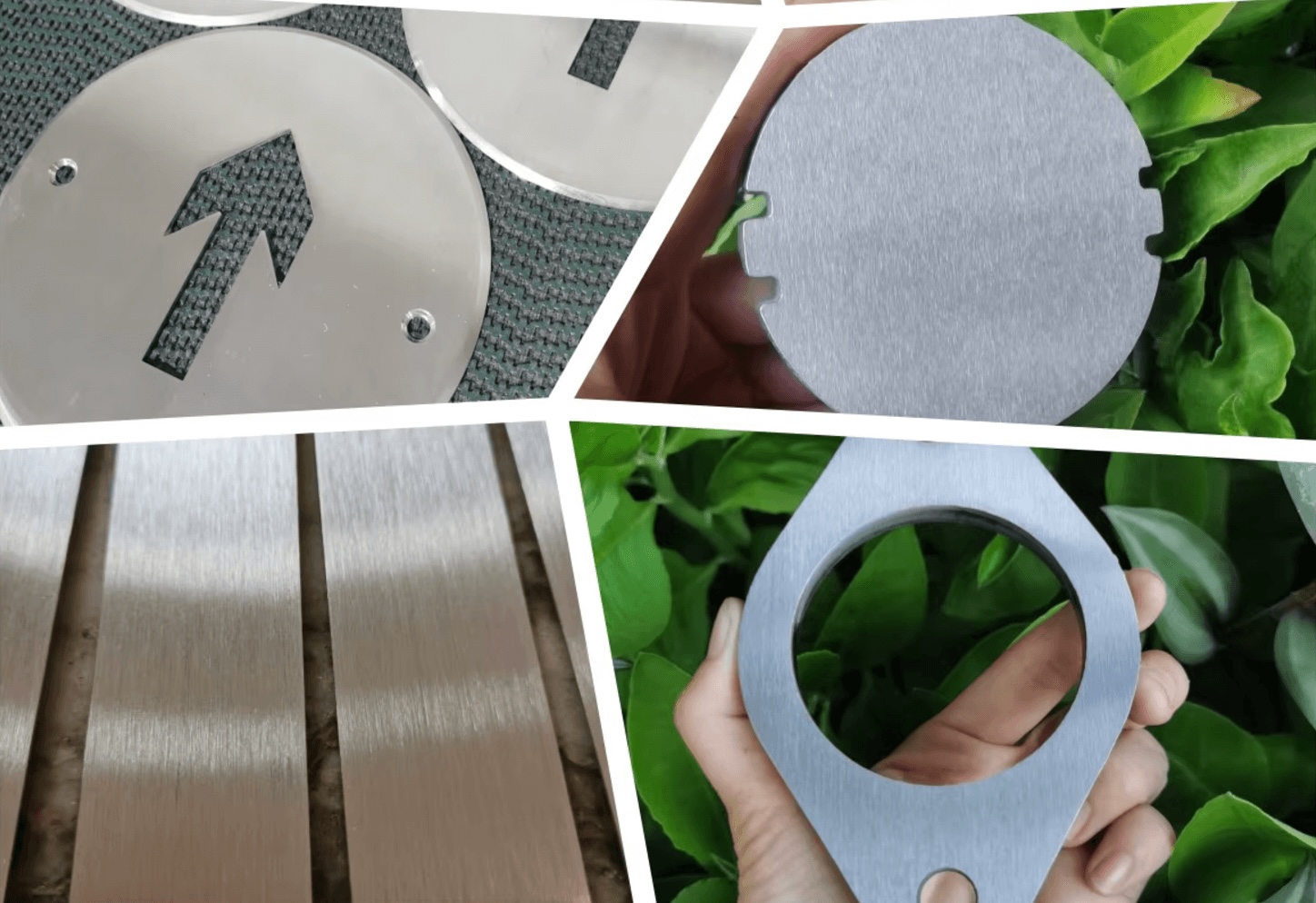

Complementing rolling brush technology, metal sanding brush deburring machines provide fine surface finishing by sanding metal profiles after initial deburring. These machines help achieve smooth, polished surfaces, perfect for profiles used in decorative or high-precision applications.

Applications of Metal Profile Deburring Machines

- Construction: Finishing structural steel angles, channels, and beams.

- Automotive: Smoothing edges on tubular frames and parts.

- Furniture Manufacturing: Creating safe, finished metal profiles for frames and supports.

- Electrical Industry: Deburring enclosures and panel profiles.

- General Fabrication: Any metal profile requiring burr-free, blunted edges for safety and appearance.

Metal Profile Deburring Blunting Machine – Specification Sheet

| Item | Specification |

|---|---|

| Model Name | MS-1000RB |

| Deburring Method | Rolling Brush + Sanding Brush |

| Applicable Materials | Carbon Steel, Stainless Steel, Aluminum, Copper |

| Workpiece Type | Metal Profiles, Flat Bars, Rectangular Tubes |

| Max Processing Width | 1000 mm |

| Max Workpiece Thickness | 0.5 – 100 mm |

| Min Workpiece Length | 100 mm |

| Feeding Speed | 0.5 – 8 m/min (adjustable) |

| Brush Rotation Speed | 1000 – 1500 RPM (adjustable) |

| Brush Type | Rolling Brush (Nylon/Wire), Sanding Brush (Abrasive) |

| Dust Collection Port | Yes (Integrated with optional dust collector) |

| Control System | PLC Touchscreen Operation |

| Power Supply | 380V / 50Hz / 3 Phase (Customizable) |

| Total Power | Approx. 9.5 kW |

| Machine Dimensions | 2200 × 1600 × 1600 mm (L × W × H) |

| Net Weight | Approx. 1200 kg |

| Optional Features | Vacuum table, magnetic conveyor, auto brush cleaner |

| Certifications | CE, ISO9001 |

| Application Industries | Metal Fabrication, Sheet Metal Processing, Furniture, Construction, HVAC |

Conclusion: Your Complete Metal Finishing Solution

Investing in a metal profile deburring blunting machine equipped with rolling and sanding brush technology guarantees superior edge finishing, improved safety, and enhanced product quality. Whether you handle heavy steel profiles or delicate aluminum extrusions, these machines provide reliable, automated solutions to meet your production demands.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao