Metal Chamfering Machine for Sheet Edge Beveling and Polishing

Whether you’re working with carbon steel, stainless steel, or aluminum, this machine combines chamfering and flat sheet polishing in one powerful unit.

From fabrication workshops to industrial production lines, this machine improves productivity, enhances safety, and ensures perfect edge quality.

Table of Contents

Why Choose Our Flat Sheet Polishing and Chamfering Machine?

Our equipment is purpose-built to meet the demanding needs of sheet metal manufacturers:

Precise beveling angles from 15° to 45°, adjustable according to project needs

Wide compatibility with carbon steel, stainless steel, aluminum, and alloy sheets

Dual function machine — combines chamfering and surface polishing for complete edge finishing

Smooth operation with automatic feed, minimal vibration, and consistent cutting pressure

Reduce post-processing with clean, uniform edges that require no hand grinding

Heavy-duty frame designed for long service life in industrial environments

Whether you’re preparing parts for welding or need high-end visual finishes, our flat sheet polishing machine delivers.

Key Features of the Carbon Steel Chamfering Machine

Built for precision, durability, and performance, this machine offers:

Adjustable Chamfer Depth and Angle – Easily control the bevel width and angle for different job specs

High-Speed Rotating Cutter Head – Equipped with tungsten or carbide inserts for long tool life

Integrated Surface Polisher – Removes oxidation and smooths the sheet surface in one pass

Sturdy Worktable and Clamping System – Keeps sheets stable and ensures uniform chamfering

Touchscreen Controller (PLC Optional) – Fast parameter adjustments and diagnostics

Compact Footprint – Fits easily into small workshops or production lines

This carbon steel chamfering machine simplifies edge prep and boosts consistency.

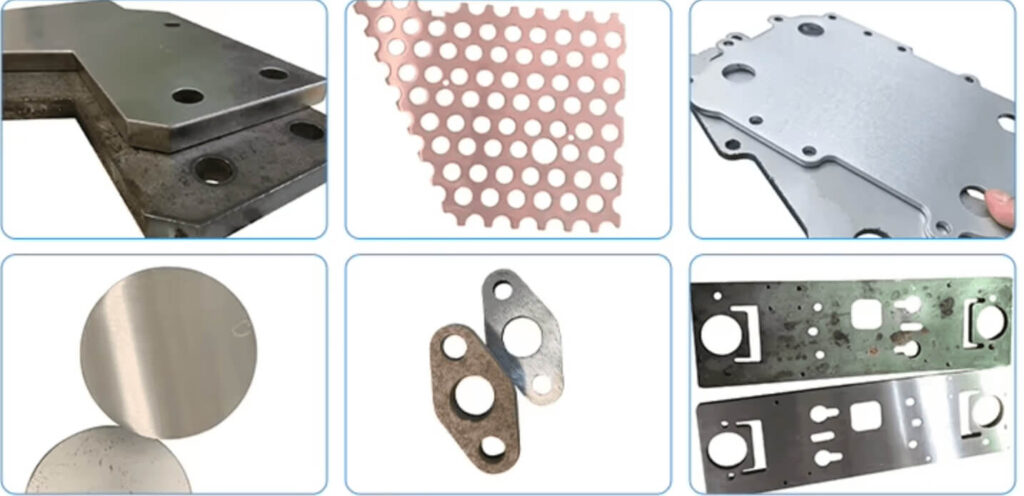

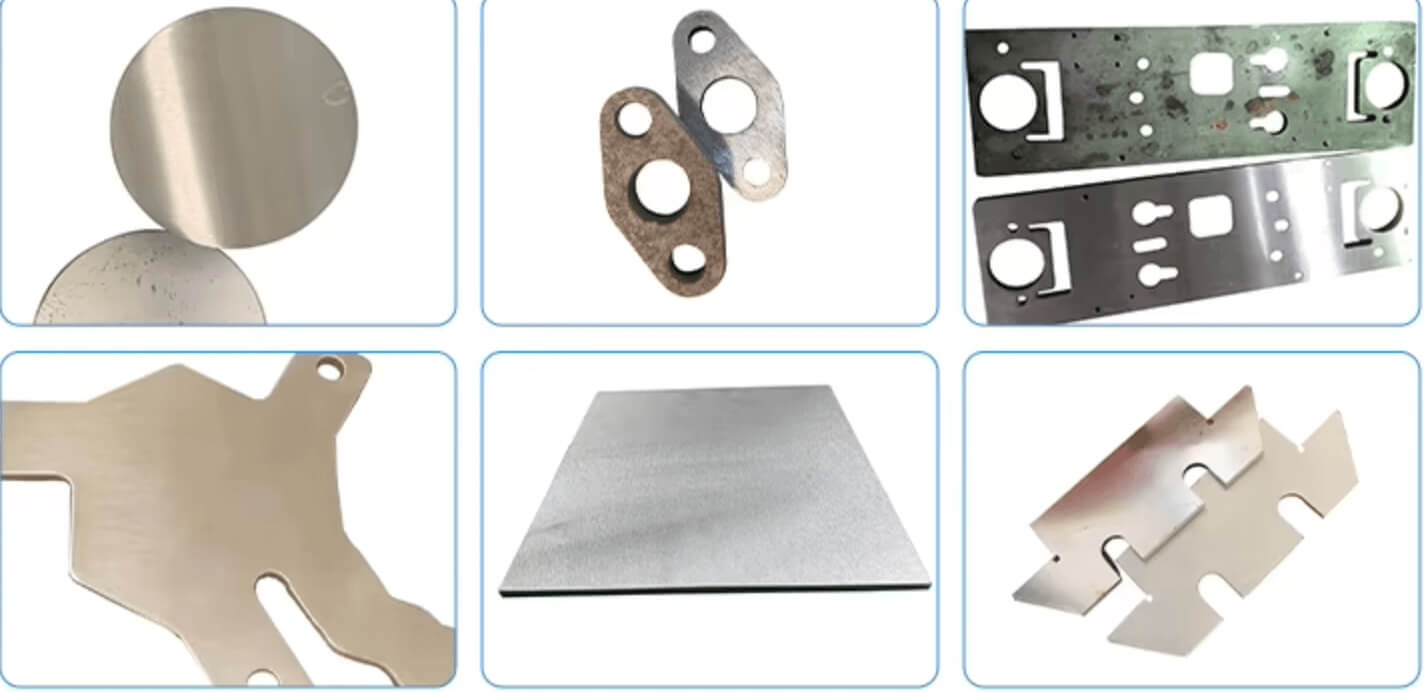

Applications: From Welding Prep to Decorative Panels

The machine is ideal for a variety of industries:

Welding preparation — chamfered edges improve weld penetration and reduce defects

Machinery manufacturing — clean edges ensure safety and assembly precision

Sheet metal parts fabrication — improves product finish and reduces manual labor

Decorative panel production — polished surfaces and uniform bevels for a premium appearance

Coating or painting pre-treatment — edges are cleaned and ready for finishing

Whether you’re handling mild steel, stainless, or aluminum, this machine enhances your workflow.

Technical Specifications of the Metal Chamfering & Polishing Machine

| Parameter | Value |

|---|---|

| Chamfering Angle Range | 15°–45° (adjustable) |

| Max Sheet Thickness | 2–30 mm |

| Max Sheet Width | 1300 mm (customizable) |

| Chamfering Speed | 0–5 m/min |

| Polishing Speed | 0–10 m/min |

| Cutter Head Motor Power | 4 kW |

| Polishing Motor Power | 3 kW |

| Voltage | 380V / 50Hz (customizable) |

| Supported Materials | Carbon steel, stainless steel, aluminum |

| Machine Dimensions | 2200 × 1600 × 1500 mm |

Conclusion

Whether you’re working with mild steel panels or high-end stainless steel sheets, this metal chamfering machine delivers the edge quality and surface finish your production demands. By integrating flat sheet polishing and chamfering into one machine, you save space, time, and labor costs—without compromising precision or finish.

From weld prep to decorative finishing, it’s the ideal carbon steel chamfering machine for today’s metalworking industry.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao