Master Precision and Efficiency with Industrial Metal Belt Sanders

From heavy-duty grinding to delicate finishing, these machines are designed to meet diverse metalworking demands.

Let’s explore what makes an Industrial Metal Belt Sander the best choice for metal work, and why a Metal Belt Grinder for Knife Making is essential for craftsmen.

Table of Contents

What Is an Industrial Metal Belt Sander?

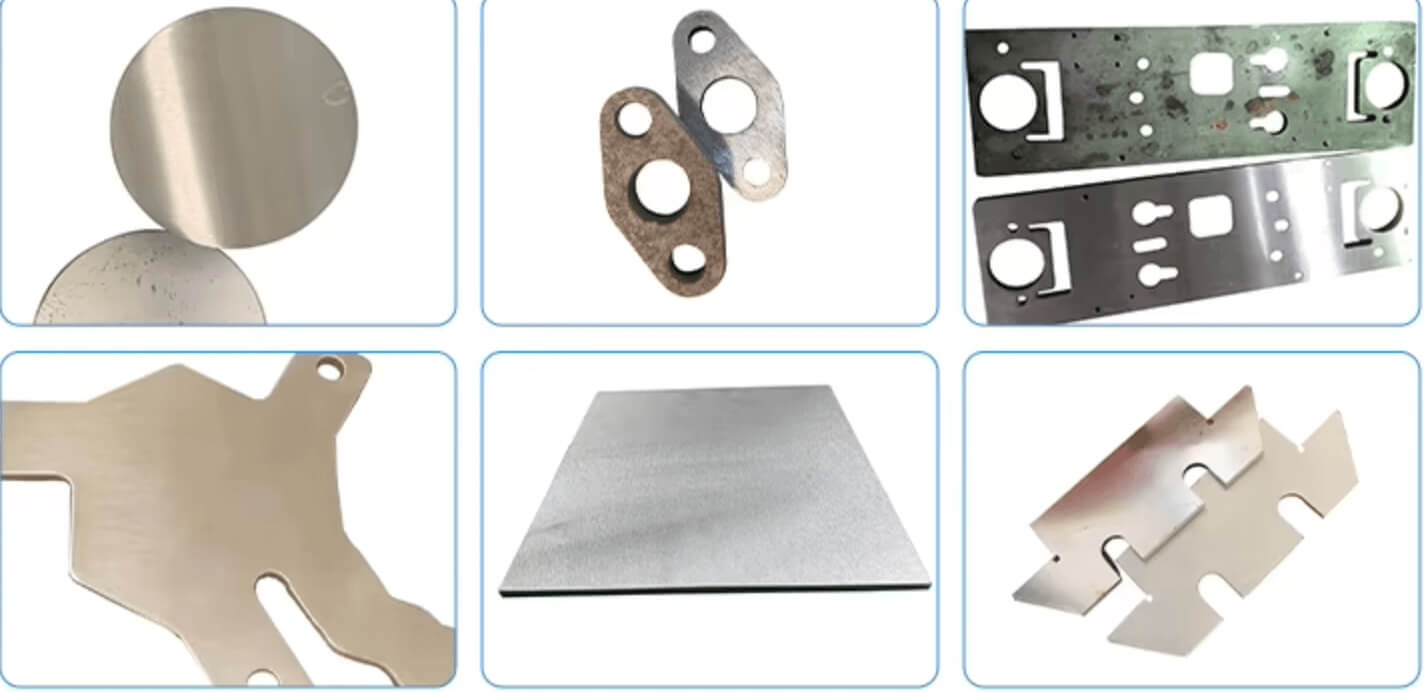

An Industrial Metal Belt Sander is a powerful sanding machine designed specifically for processing metal parts. Featuring heavy-duty abrasive belts, these sanders can efficiently remove excess material, smooth welds, deburr edges, and prepare surfaces for further finishing.

Core Features:

- Robust construction for continuous heavy use

- Variable speed control for adapting to different metals and thicknesses

- Wide belt options to handle large or small workpieces

- Dust collection ports for cleaner operation

These machines are a backbone for metal fabrication shops, automotive repair, and manufacturing plants where consistent, high-quality sanding is non-negotiable.

Why Is It the Best Belt Sander for Metal Work?

The Best Belt Sander for Metal Work offers a blend of power, precision, and versatility:

- Adjustable Speed: Tailor sanding speed to delicate aluminum or tough steel

- Durable Belts: Use high-grade abrasive belts that last longer and perform better

- Ergonomic Design: Easy to operate with minimal fatigue, even in long shifts

- Safety Features: Guards and emergency stops to protect operators

For fabricators, these sanders reduce manual labor, increase throughput, and ensure surfaces meet exacting standards before welding, painting, or assembly.

Metal Belt Grinder for Knife Making: Craftsmanship Meets Technology

Knife making demands exceptional precision and finish. A Metal Belt Grinder for Knife Making is specialized for shaping blades, beveling edges, and polishing final products.

Advantages for Knife Makers:

Fine control for shaping complex curves and bevels

Ability to switch belts quickly for different grit levels

Smooth and even material removal without overheating the blade

Compact models ideal for custom shops or hobbyists

Using the right grinder improves blade sharpness, durability, and aesthetic appeal, giving craftsmen an edge in the competitive knife market.

Applications Across Industries

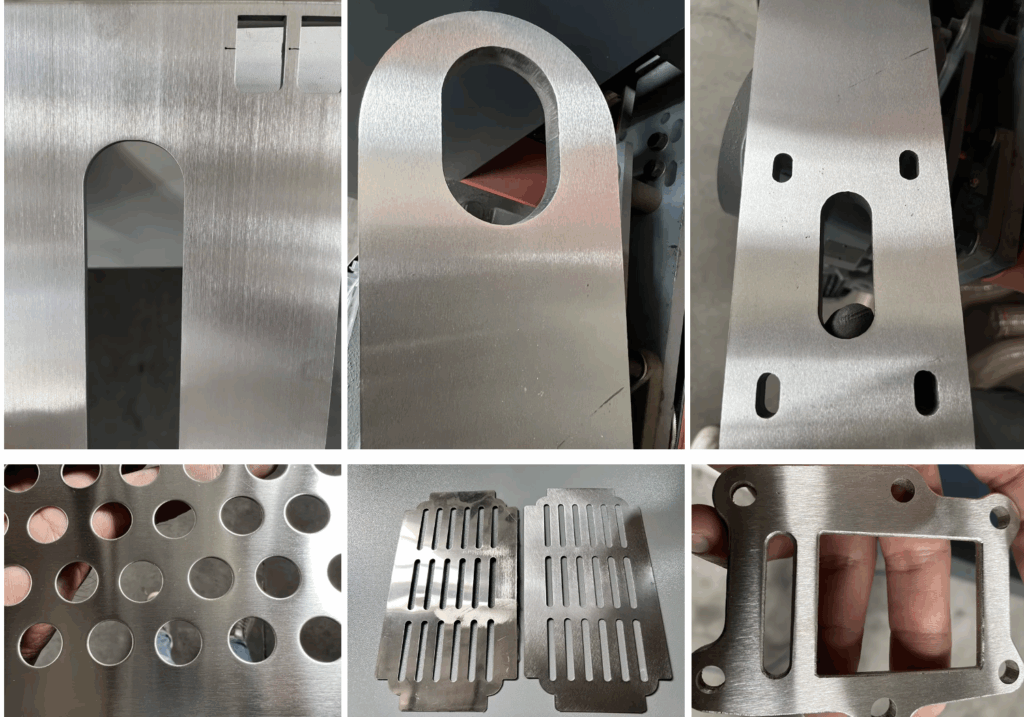

- Metal Fabrication: Deburring, leveling, and surface prep on sheet metal and parts

- Automotive Repair: Refinishing chassis, smoothing weld joints, and shaping components

- Knife Manufacturing: Precision grinding, sharpening, and polishing blades

- Tool and Die Making: Accurate finishing of metal tools and molds

- Construction: Preparing metal parts for assembly or coating

How to Choose the Right Metal Belt Sander or Grinder?

When selecting your Industrial Metal Belt Sander or Metal Belt Grinder, consider:

- Workpiece Size: Choose belt width and machine size accordingly

- Material Type: Different metals require specific abrasive types and speeds

- Motor Power: Higher power suits heavy-duty, continuous operations

- Speed Adjustability: Crucial for versatile metalworking

- Dust Management: Important for health and maintenance

- Additional Features: Quick belt change, coolant options, and ergonomic design

Conclusion

Investing in a high-quality Industrial Metal Belt Sander, the Best Belt Sander for Metal Work, or a specialized Metal Belt Grinder for Knife Making ensures efficiency, precision, and superior finish. Whether for industrial production or artisanal crafting, the right equipment makes all the difference.

👉 Contact us today for expert advice and personalized solutions tailored to your metalworking needs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao