Key Role of Metal Sanding Machines in Metal Surface Treatment

These machines use abrasive materials to finely process the surface of metal, effectively removing surface defects, improving surface smoothness, and preparing the material for subsequent coating, plating, or other surface treatments. Below are the key roles of metal sanding machines in surface treatment:

Table of Contents

Removal of Surface Defects and Oxidation

During metal processing, surfaces may develop oxide layers, welding residues, oils, or other impurities, which can affect subsequent treatment processes. Metal sanding machines, through the use of sanding belts, sandpaper, and other abrasives, effectively remove these contaminants and irregularities, ensuring the metal surface is clean and smooth

Improvement of Surface Roughness

Metal sanding machines improve the roughness of metal surfaces by removing burrs and irregular particles, resulting in a smoother finish. This is particularly important in applications that require high precision and surface quality, such as in the aerospace, automotive, and medical industries.

Preparation for Subsequent Surface Treatments

Metal sanding machines are not only used for surface smoothing but also to prepare the metal surface for subsequent treatment processes, such as electroplating, spraying, or polishing. A smooth metal surface ensures uniform adhesion of coatings, enhancing their bonding strength and durability, which improves corrosion resistance and aesthetic appearance.

Enhanced Surface Hardness and Wear Resistance

By appropriately sanding the metal surface, soft layers can be removed, increasing the hardness and wear resistance of the material. For metal parts requiring high hardness, sanding not only enhances aesthetic quality but also prolongs the product’s service life and durability.

Improved Aesthetic Appeal

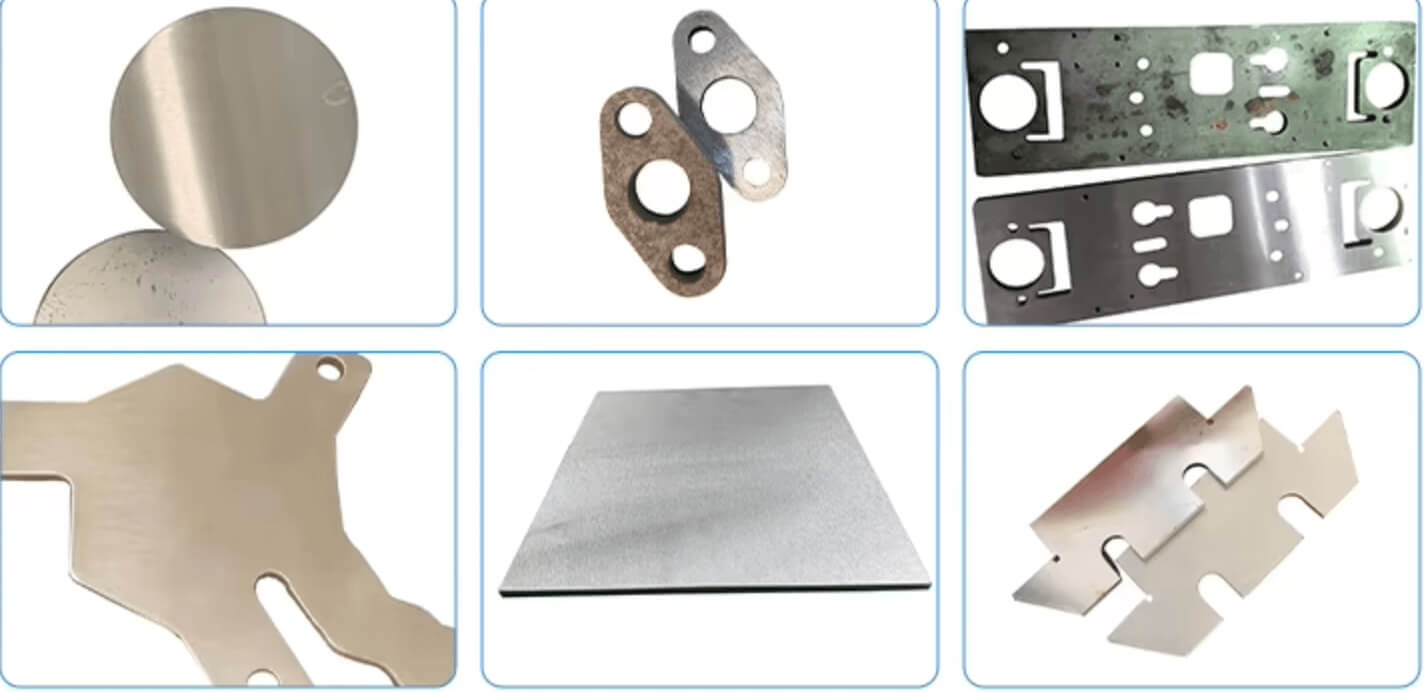

Metal sanding machines are suitable for a variety of metal materials, including stainless steel, aluminum alloys, copper, and iron, and are widely used across different industries. Whether it’s for simple oxidation removal or complex surface finishing, sanding machines deliver efficient and consistent results.

Conclusion

Metal sanding machines play a vital role in the surface treatment process of metalworking. They not only improve surface quality and remove defects but also create ideal conditions for subsequent treatments, enhancing the functionality and aesthetics of metal products. As the industrial demand for high-quality surface treatments continues to grow, the application of metal sanding machines will become even more widespread across various metalworking sectors.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao