Key Features of Metal Sanding Machines: Auto Adjustment & Adjustable Speed

Two standout features—automatic adjustment and adjustable speed—have transformed the sanding process, allowing for better control, consistency, and customization in surface finishing. In this article, we explore the technological innovations behind these features and how they contribute to the performance of metal sanding machines.

Table of Contents

Automatic Adjustment Function:

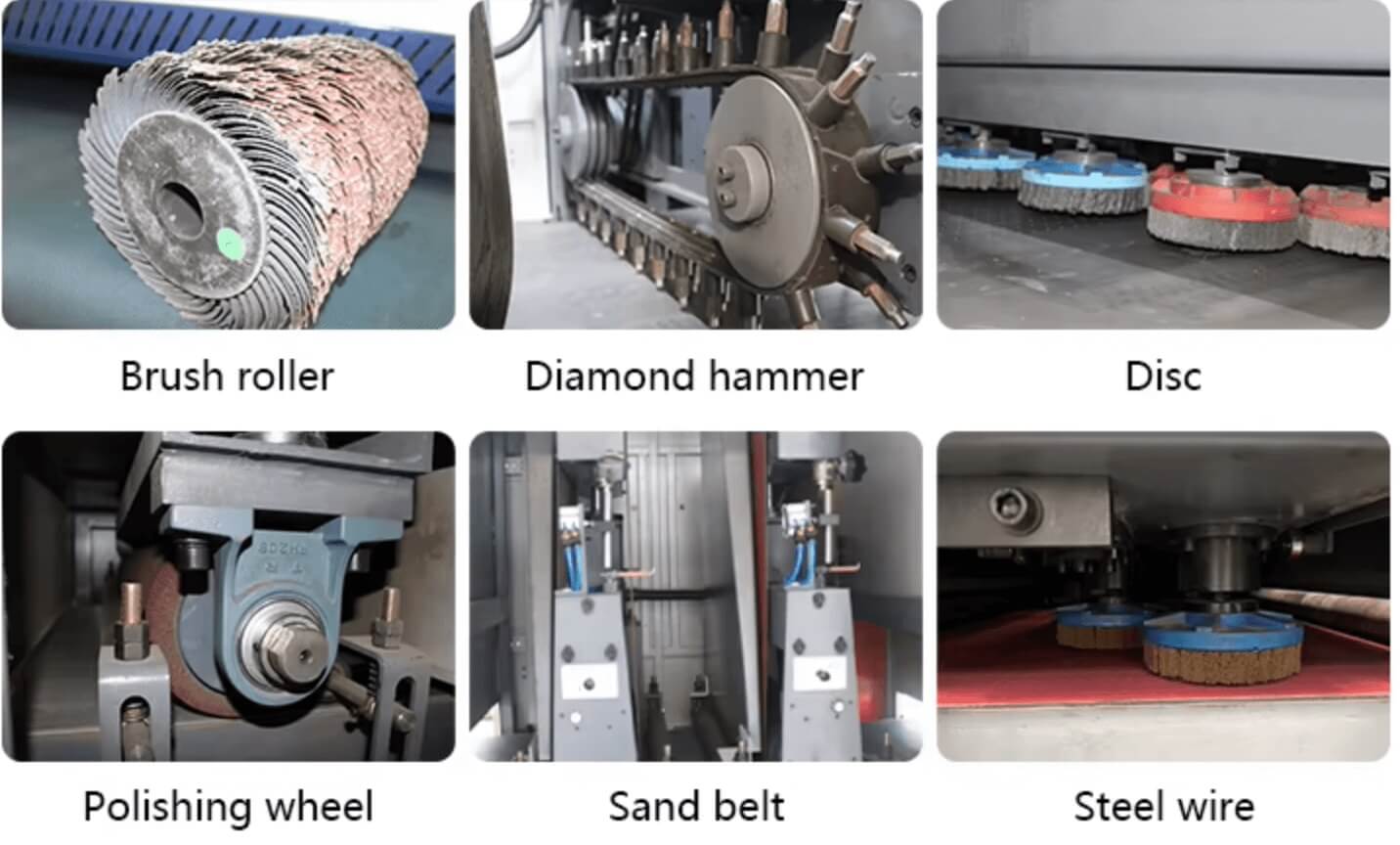

One of the most advanced features in modern metal sanding machines is the automatic adjustment system. This system enables the machine to automatically adjust critical parameters such as pressure and sanding belt speed according to the type of metal being processed. By continuously monitoring and adapting to the material’s characteristics, the automatic adjustment function ensures that the sanding process remains consistent and precise.

- How It Works: The system uses sensors and real-time data feedback to detect the material’s surface properties (e.g., hardness, thickness, and roughness). Based on this data, the machine adjusts the pressure applied by the sanding belt and modifies the speed to optimize the sanding process.

- Benefits: This automatic adjustment ensures uniform results, reduces the risk of surface defects, and minimizes the need for manual intervention. It also allows operators to process different metal types without having to manually recalibrate the machine.

Adjustable Speed:

The adjustable speed feature is another key innovation in modern metal sanding machines. This functionality allows operators to tailor the sanding belt speed to suit various metal surface finishing needs, enhancing both flexibility and control over the process.

- How It Works: Machines with adjustable speed settings allow users to fine-tune the sanding belt speed, typically ranging from low to high, depending on the material and the desired finish. For example, higher speeds are ideal for rough sanding or deburring, while slower speeds are better for polishing and fine finishing.

- Benefits: The ability to adjust speed provides greater versatility, enabling the machine to handle different tasks and materials. It also helps prevent overheating or over-abrasion of delicate materials, ensuring a more controlled and efficient sanding process.

Precision Control System:

Modern metal sanding machines are equipped with precision control systems, often powered by advanced numerical control (NC) or computer numerical control (CNC) technology. These systems enable fine-tuned adjustments to various parameters such as sanding speed, pressure, and angle of operation.

- How It Works: The control system uses digital inputs to adjust machine settings in real-time, allowing for high-precision sanding and consistent results across multiple production runs.

- Benefits: A CNC-powered sanding machine offers greater accuracy, eliminating human error and ensuring that each metal component meets strict quality standards. This is especially important in industries like aerospace, automotive, and electronics, where precise surface finishes are critical.

High-Efficiency Performance:

A key feature of modern metal sanding machines is their ability to operate efficiently, even during extended periods of use. High-performance motors and power transmission systems ensure that the machine runs smoothly and effectively, providing the required speed and torque to process metals quickly and evenly.

- How It Works: Advanced motors and robust transmission systems provide the necessary power to drive the sanding belt at consistent speeds, reducing downtime and maintaining high output.

- Benefits: This increased efficiency not only boosts productivity but also reduces energy consumption compared to older, less efficient models. By ensuring a steady sanding process without fluctuations, the machine achieves better surface finishes while minimizing material waste.

Conclusion

The technical features of modern metal sanding machines, particularly automatic adjustment and adjustable speed, significantly enhance the sanding process by offering greater control, precision, and efficiency. With the integration of these features, metal sanding machines are more adaptable to different materials and tasks, providing consistent results and improving overall productivity. Whether in automotive manufacturing, aerospace, or electronics, these innovations enable manufacturers to achieve superior surface finishes with minimal effort and maximum efficiency.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

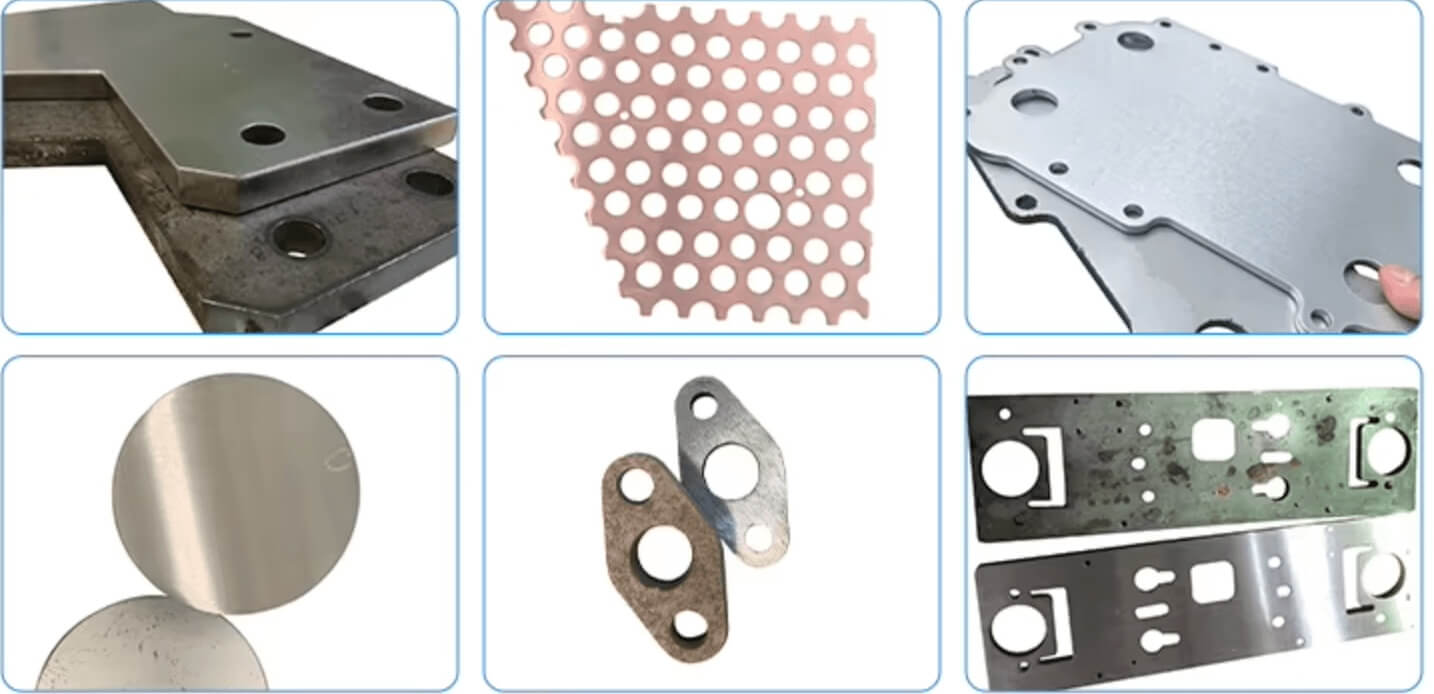

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao