高品質金属部品に適したバリ取り機の選び方

これらの機械は、金属部品の安全性を確保し、機能性を向上させ、外観を向上させるため、自動車、航空宇宙、製造業などの産業において不可欠な存在となっています。この記事では、 バリ取り機、その利点、そしてニーズに合った適切なものを選択する方法について説明します。

目次

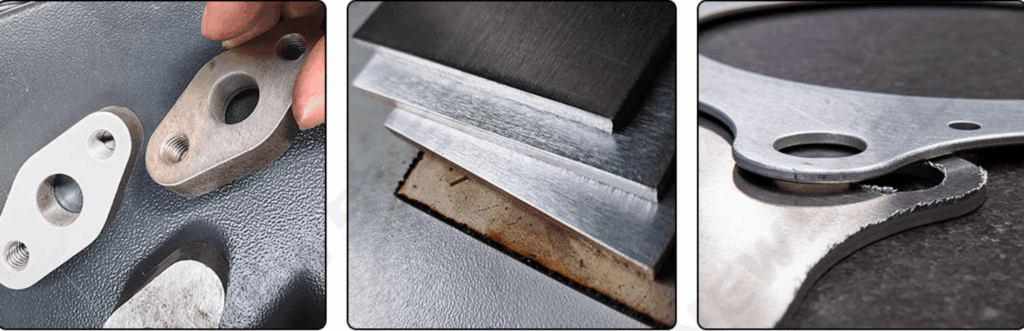

バリ取り機の種類

研磨ベルトバリ取り機

研磨ベルトマシン 回転研磨ベルトを用いて金属部品のバリを除去します。大量生産に最適で、様々な金属に対応し、均一な仕上がりを実現します。

回転式バリ取り機

ロータリー式研磨機は、回転ブラシまたはホイールを使用してバリを除去します。繊細な仕上げが必要な繊細な部品に適しています。

タンブリングバリ取り機

タンブリングマシンは、振動バレルと研磨材を用いて、小型から中型の金属部品のバリ取りと仕上げを行います。大量処理に最適です。

ロボットバリ取りシステム

自動化ロボットシステムは、複雑な部品の精密バリ取りを実現します。これらのシステムは再現性を確保し、高精度が求められる産業に最適です。

湿式バリ取り機

湿式バリ取り機は、研磨材とクーラントを組み合わせてバリを除去し、過熱を防ぎます。熱に弱い材料に最適です。

バリ取り機の利点

安全性と効率性の向上

バリ取り機 鋭利なエッジを排除することで、怪我のリスクを軽減し、作業者の安全性を高めます。自動化システムにより、処理速度と一貫性も向上します。

強化された部品品質

バリ取り機はバリや欠陥を取り除くことで金属部品が正しくフィットして機能することを保証し、組み立て中に問題が発生するのを防ぎます。

生産性の向上

自動バリ取りシステムは人件費と処理時間を削減するため、大量生産に最適です。

コスト効率が高い

バリ取り機に投資すると、手作業が減り、やり直しが最小限に抑えられ、生産能力が向上し、長期的なコスト削減につながります。

適切なバリ取り機の選び方

金属の種類と量を考慮する

作業する材料(アルミニウム、スチールなど)と生産量(小ロットか大規模生産か)に基づいて機械を選択します。

希望の仕上がりを決める

磨き仕上げには、回転式または湿式バリ取り機が最適です。素早く粗いバリ取りには、ベルト研磨機の方が効率的です。

自動化 vs. 手動

自動化されたロボット システムは複雑な部品に対して高い精度を提供しますが、手動の機械はより単純なタスクや小ロットに適しています。

結論

バリ取り機 自動車や航空宇宙産業などの産業において、金属部品の品質、安全性、効率性の向上に不可欠な役割を果たしています。大量生産向けのソリューションから複雑な部品の精密バリ取りシステムまで、適切な機械を選択することで生産を効率化し、安定した結果を得ることができます。適切な設備に投資することで、製造プロセスを強化し、優れた部品仕上げを実現できます。

製品カテゴリー

最近のニュース

当社を選ぶ理由

- CNC 機器製造における 16 年の専門知識。

- 22年以上の経験 弊社の熟練した技術チームが対応いたします。

- 100か国以上で信頼されています と 800以上のインストール 世界的に。

- 10,000平方メートルの製造施設大規模生産に対応できる設備を備えています。

- 20名以上の国際営業担当者からなる専任チーム.

- 24時間サポート 24時間365日のアフターサービス付き。

- 厳格な品質保証システム 最高品質の製品を確保するため。

- 協力的なアプローチ パートナー、クライアント、スタッフの成功を促進します。

- 包括的なターンキーソリューション 製造、サービス、販売を統合します。

- あらゆる種類の金属ワークピースを扱えるように設計多様な業界のニーズに応えます。

お問い合わせ

- 電話:86-531-88804531

- 電話:86 15562582965

- メールアドレス: [email protected]

- 住所:青島市王台公業産業