Scegliere la macchina sbavatrice giusta per parti metalliche di alta qualità

Queste macchine garantiscono la sicurezza, migliorano la funzionalità e migliorano l'aspetto dei componenti metallici, rendendole vitali in settori come quello automobilistico, aerospaziale e manifatturiero. Questo articolo esplora le tipologie di macchine sbavatrici, i loro vantaggi e come scegliere quello più adatto alle tue esigenze.

Sommario

Tipi di macchine sbavatrici

Macchine sbavatrici a nastro abrasivo

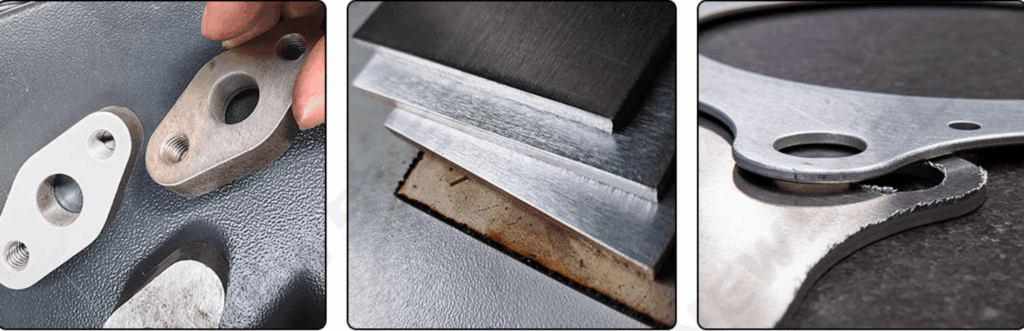

Macchine a nastro abrasivo Utilizzano nastri abrasivi rotanti per rimuovere le bave dai componenti metallici. Ideali per produzioni ad alto volume, possono trattare una vasta gamma di metalli, garantendo una finitura uniforme.

Macchine sbavatrici rotanti

Le macchine rotative utilizzano spazzole o ruote rotanti per rimuovere le bave. Sono adatte a pezzi delicati che richiedono una finitura accurata.

Macchine sbavatrici a tamburo

Le macchine burattatrici utilizzano un tamburo vibrante e un abrasivo per sbavare e rifinire componenti metallici di piccole e medie dimensioni. Perfette per la lavorazione di grandi quantità.

Sistemi di sbavatura robotizzati

I sistemi robotizzati automatizzati garantiscono la sbavatura di precisione di componenti complessi. Questi sistemi garantiscono ripetibilità e sono adatti ai settori ad alta precisione.

Macchine per sbavatura a umido

Le sbavatrici a umido utilizzano materiali abrasivi combinati con refrigerante per rimuovere le bave e prevenire il surriscaldamento. Ideali per materiali sensibili al calore.

Vantaggi delle macchine sbavatrici

Maggiore sicurezza ed efficienza

Macchine sbavatrici Eliminano i bordi taglienti, riducendo il rischio di infortuni e aumentando la sicurezza dei lavoratori. I sistemi automatizzati migliorano anche la velocità e la coerenza delle lavorazioni.

Qualità migliorata delle parti

Rimuovendo sbavature e imperfezioni, le macchine sbavatrici garantiscono che i componenti metallici si adattino e funzionino correttamente, prevenendo problemi durante l'assemblaggio.

Aumento della produttività

I sistemi di sbavatura automatizzati riducono i costi di manodopera e i tempi di lavorazione, rendendoli ideali per la produzione di grandi volumi.

Conveniente

Investire in una macchina sbavatrice riduce il lavoro manuale, riduce al minimo le rilavorazioni e migliora la capacità produttiva, con conseguenti risparmi sui costi a lungo termine.

Come scegliere la macchina sbavatrice giusta

Considerare il tipo e il volume del metallo

Scegli la macchina in base al materiale che stai lavorando (ad esempio alluminio, acciaio) e al volume di produzione (piccoli lotti o operazioni su larga scala).

Determinare la finitura desiderata

Per una finitura lucida, le migliori sono le sbavatrici rotative o a umido. Per una sbavatura rapida e grossolana, le macchine a nastro abrasivo sono più efficienti.

Automazione vs. Manuale

I sistemi robotici automatizzati offrono una maggiore precisione per le parti complesse, mentre le macchine manuali sono adatte per attività più semplici e lotti più piccoli.

Conclusione

Macchine sbavatrici svolgono un ruolo cruciale nel migliorare la qualità, la sicurezza e l'efficienza dei componenti metallici in settori come quello automobilistico e aerospaziale. Che abbiate bisogno di una soluzione per grandi volumi o di un sistema di sbavatura di precisione per componenti complessi, la scelta della macchina giusta può semplificare la produzione e garantire risultati costanti. Investite nelle attrezzature giuste per migliorare il vostro processo di produzione e ottenere finiture superiori dei componenti.

Categorie di prodotti

Notizie recenti

Perché scegliere noi

- 16 anni di esperienza nella produzione di apparecchiature CNC.

- Oltre 22 anni di esperienza dal nostro team tecnico qualificato.

- Affidabile in oltre 100 paesi con Oltre 800 installazioni a livello globale.

- Stabilimento produttivo di 10.000 metri quadrati, attrezzato per la produzione su larga scala.

- Un team dedicato di oltre 20 rappresentanti di vendita internazionali.

- Supporto 24 ore su 24 con servizio post-vendita 24 ore su 24, 7 giorni su 7.

- Un rigoroso sistema di garanzia della qualità per garantire prodotti di prima qualità.

- Un approccio collaborativo promuovere il successo di partner, clienti e dipendenti.

- Soluzioni complete chiavi in mano integrando produzione, assistenza e vendite.

- Progettato per gestire tutti i tipi di pezzi metallici, soddisfacendo le diverse esigenze del settore.

Contattaci

- Tel: 86-531-88804531

- Telefono: 86 15562582965

- E-mail: [email protected]

- Indirizzo: Industria Wangtai Gongye, Qingdao