Macchina per il taglio laser automatico di parti, lucidatura e levigatura di superfici metalliche piane.

Ideale per i settori che richiedono finiture impeccabili su componenti tagliati al laser, questa macchina automatizza il trattamento superficiale per eliminare imperfezioni come sbavature, graffi e ossidazione. Progettata per operazioni ad alta velocità, garantisce una qualità costante nei settori automobilistico, aerospaziale, elettronico e della lavorazione dei metalli per l'architettura. Grazie a controlli robotici avanzati e utensili adattivi, riduce i costi di manodopera, riduce al minimo gli sprechi di materiale e migliora la produttività in ambienti di produzione esigenti.

Sommario

Precisione automatizzata per superfici metalliche impeccabili

Questa macchina sfrutta l'automazione robotica per garantire una precisione micrometrica nella lucidatura e nella sbavatura. Dotata di controlli CNC programmabili, si adatta a geometrie complesse, garantendo finiture superficiali uniformi su acciaio inossidabile, alluminio, ottone e altri metalli.

Lucidatura e sbavatura integrate in un unico sistema

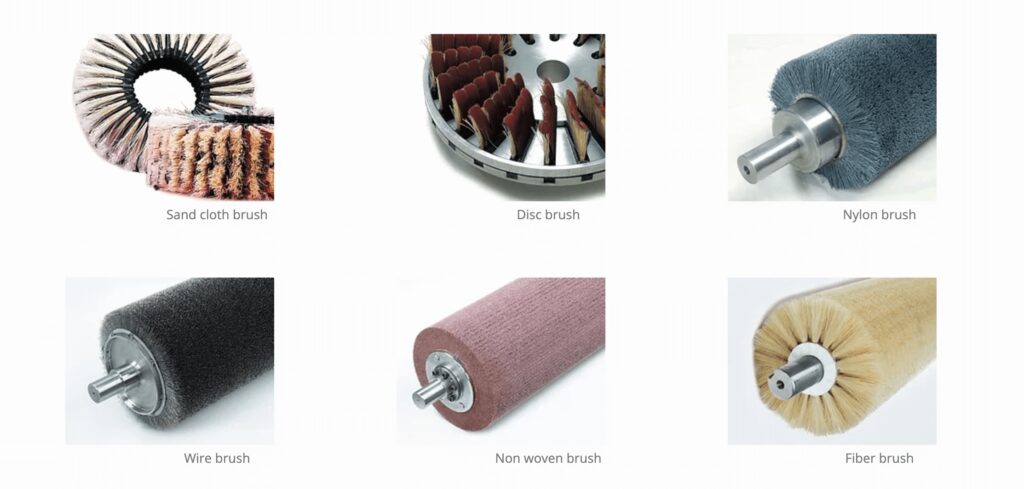

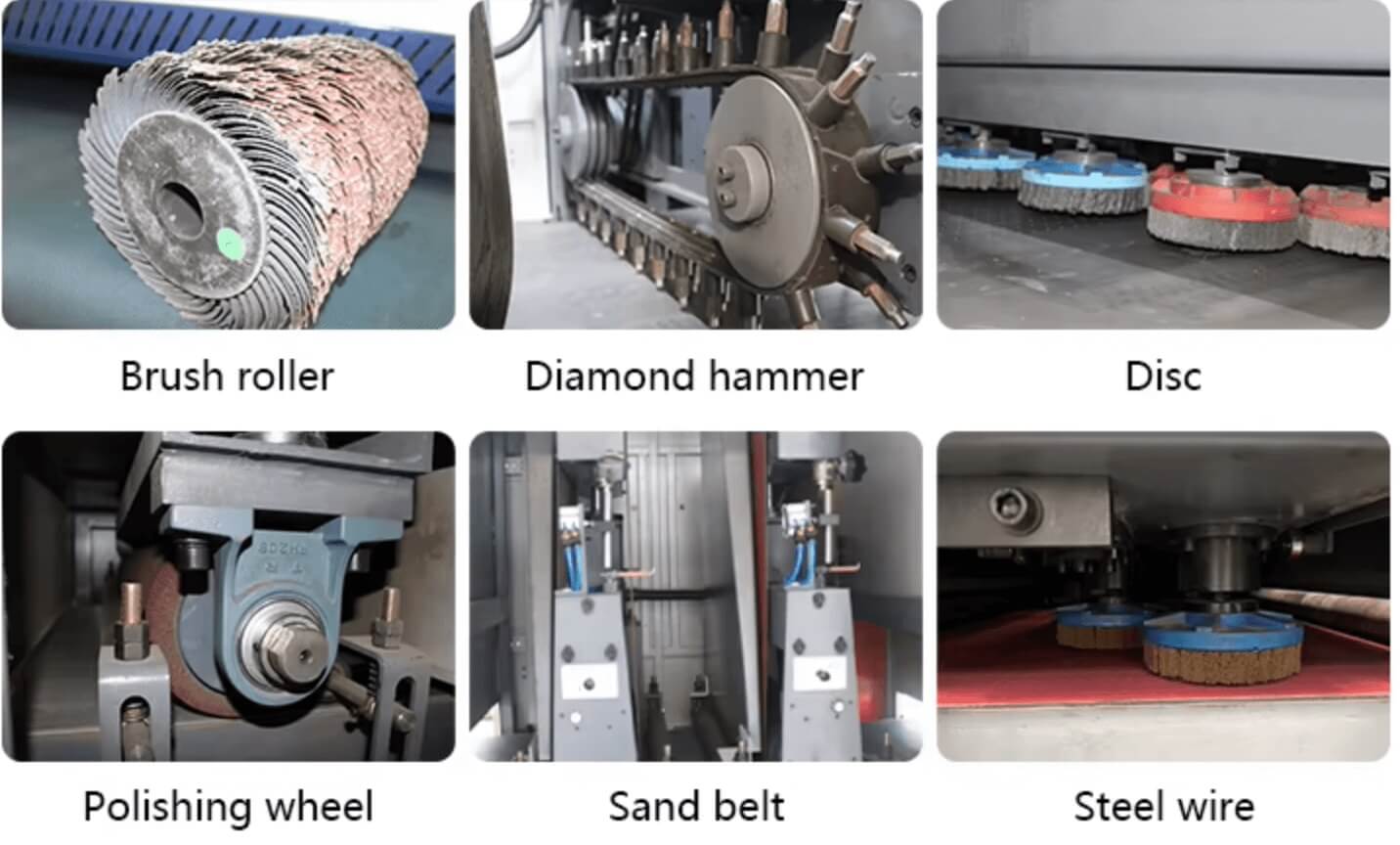

Passa senza problemi dal taglio laser alla finitura con un'unica macchina. Il design integrato include nastri abrasivi regolabili, spazzole rotanti e teste di levigatura orbitale per gestire bordi irregolari, micro-bave e levigatura superficiale senza intervento manuale.

Controllo avanzato della pressione adattiva

Sensori intelligenti regolano dinamicamente la pressione di lucidatura in base allo spessore del materiale e alle irregolarità superficiali. Questo previene la sovra-rettifica, preserva l'integrità dimensionale e prolunga la durata dell'utensile.

Elaborazione ad alta velocità per flussi di lavoro industriali

Aumenta la produttività con tempi di ciclo rapidi, in grado di elaborare grandi lotti di pezzi tagliati al laser. La configurazione modulare della macchina consente la lucidatura e la sbavatura simultanee, riducendo i tempi di fermo fino a 50%.

Aspirazione della polvere e funzionamento ecologico

Il filtro HEPA integrato cattura particelle metalliche e detriti, mantenendo un ambiente di lavoro pulito e conforme agli standard di sicurezza industriale. I motori a risparmio energetico riducono i costi operativi e l'impatto ambientale.

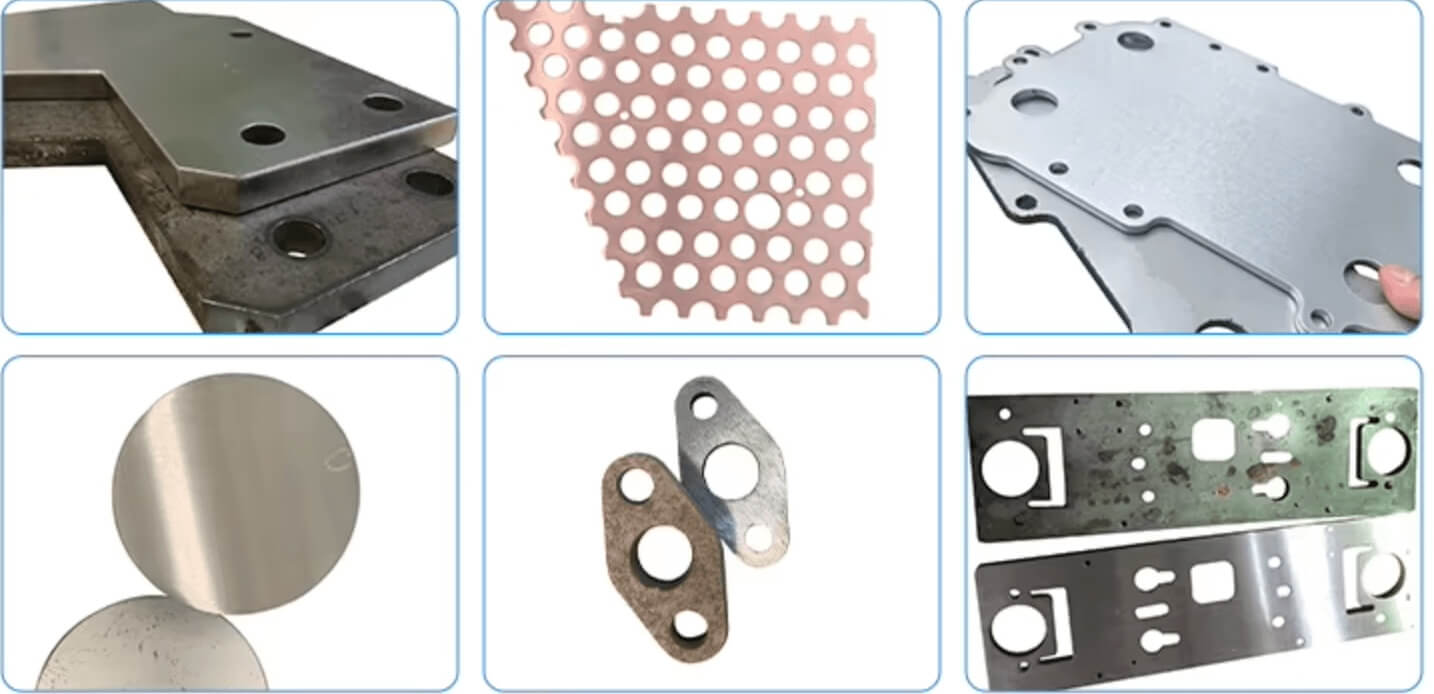

Applicazioni versatili in tutti i settori

Dai componenti dei telai automobilistici ai complessi contenitori elettronici, questa macchina eccelle in diversi settori. La sua compatibilità con lamiere piane, tubi e bordi angolati la rende indispensabile per i produttori che danno priorità a precisione e scalabilità.

Conclusione

Trasforma i tuoi flussi di lavoro post-taglio laser con Macchina levigatrice per lucidatura di parti con taglio laser automatico—una vera svolta nella finitura delle superfici metalliche. Combinando precisione robotica, tecnologia adattiva e capacità multifunzionali, affronta le sfide critiche di sbavatura, lucidatura e levigatura, riducendo al contempo i costi di produzione. Che si tratti di rifinire leghe aerospaziali o pannelli architettonici, questa macchina garantisce efficienza e ripetibilità senza pari. Investi in un sistema che eleva la qualità, rispetta gli obiettivi di sostenibilità e soddisfa i rigorosi requisiti della produzione moderna.

Categorie di prodotti

Notizie recenti

Perché scegliere noi

- 16 anni di esperienza nella produzione di apparecchiature CNC.

- Oltre 22 anni di esperienza dal nostro team tecnico qualificato.

- Affidabile in oltre 100 paesi con Oltre 800 installazioni a livello globale.

- Stabilimento produttivo di 10.000 metri quadrati, attrezzato per la produzione su larga scala.

- Un team dedicato di oltre 20 rappresentanti di vendita internazionali.

- Supporto 24 ore su 24 con servizio post-vendita 24 ore su 24, 7 giorni su 7.

- Un rigoroso sistema di garanzia della qualità per garantire prodotti di prima qualità.

- Un approccio collaborativo promuovere il successo di partner, clienti e dipendenti.

- Soluzioni complete chiavi in mano integrando produzione, assistenza e vendite.

- Progettato per gestire tutti i tipi di pezzi metallici, soddisfacendo le diverse esigenze del settore.

Contattaci

- Tel: 86-531-88804531

- Telefono: 86 15562582965

- E-mail: [email protected]

- Indirizzo: Industria Wangtai Gongye, Qingdao