Industrial Metal Belt Sander Machine | Deburring & Finishing Solutions

Whether you’re removing burrs, preparing surfaces for coating, or polishing stainless steel, investing in high-quality metal sanding equipment is crucial for consistency, productivity, and safety.

In this article, we’ll explore the benefits and specifications of a professional metal belt sander machine, and how it supports industrial metal sanding, polishing, grinding, and metal surface finishing.

Table of Contents

What Is a Metal Belt Sander Machine?

A metal belt sander machine is a powerful industrial tool designed to grind, sand, deburr, and polish various types of metal surfaces. Unlike hand-held sanders, these machines offer greater speed, precision, and uniformity across large production batches.

Key Benefits:

- High-speed abrasive belt for efficient stock removal

- Consistent surface finish across all parts

- Suitable for flat sheet metal, pipes, and structural components

- Reduces manual labor and processing time

Industrial Metal Sander for Heavy-Duty Applications

Our industrial metal sander is engineered for non-stop operation in demanding environments such as metal fabrication shops, stainless steel product lines, and sheet metal processing plants.

Application Areas:

- Stainless steel kitchen equipment

- Elevator panels and metal signage

- Aluminum, carbon steel, and brass parts

- Weld seam smoothing and deburring

Versatile Metal Sanding Equipment

Our metal sanding equipment comes with adjustable speed, multiple grit belt compatibility, and optional wet sanding systems. It supports a wide range of tasks including:

- Surface leveling

- Oxidation and rust removal

- Scratch removal

- Fine polishing for mirror finish

Sheet Metal Polishing Machine for Brushed & Mirror Finishes

The sheet metal polishing machine is ideal for achieving specific aesthetic finishes, from brushed textures to mirror-polished surfaces. It’s commonly used for decorative panels, appliance covers, and architectural components.

Features:

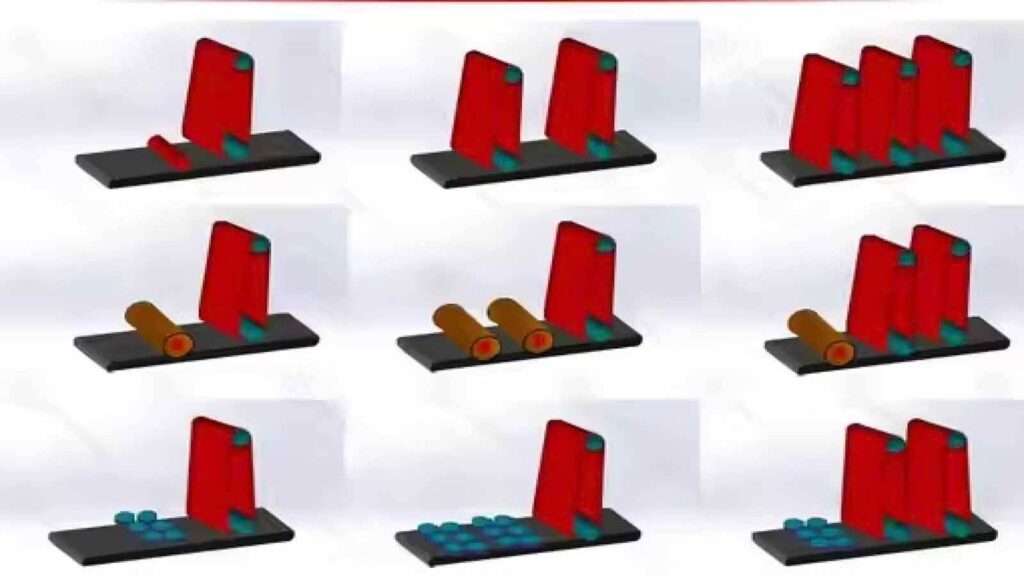

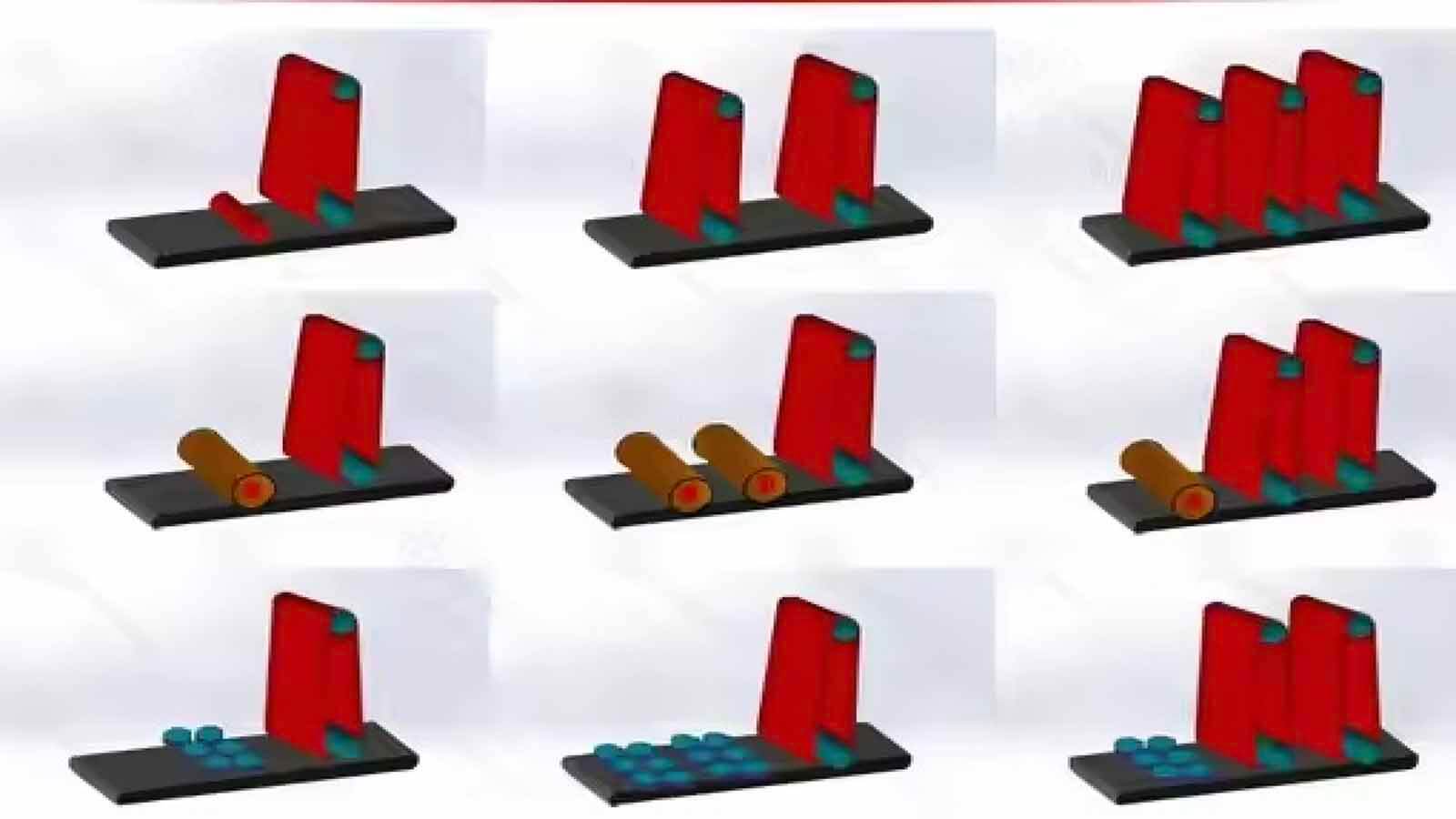

- Multi-head abrasive systems

- Variable pressure control for uniform polishing

- Water spray cooling (optional for wet polishing)

- Dust and fume collection system (dry type)

Efficient Deburring Machine for Edge and Burr Removal

After laser cutting or punching, sheet metal parts often have sharp edges and micro burrs. Our deburring machine is designed to remove these imperfections automatically.

Deburring Functions:

- Top and bottom burr removal

- Edge rounding

- Slag and oxide layer removal

- Safe for thin materials without deformation

Stainless Steel Belt Sander: Precision Meets Power

For stainless steel processing, we offer a dedicated stainless steel belt sander model that prevents overheating, ensures scratch-free polishing, and maintains material integrity.

Why It’s Ideal for Stainless Steel:

- Water-cooled belts to reduce heat buildup

- Fine-grit belt compatibility for satin and mirror finish

- Resistant to corrosion and clogging

Metal Grinding Machine with Wet Sanding Option

Our metal grinding machine can be equipped with a wet sanding system — perfect for applications where heat control and dust suppression are critical.

Wet Sanding for Metal Benefits:

- Extends belt life

- Prevents surface discoloration

- Reduces airborne dust

- Achieves cleaner, brighter finishes

Metal Belt Sander Machine Specification Table

| Item | Specification |

|---|---|

| Machine Type | Metal Belt Sander / Deburring Machine |

| Belt Size | 100mm × 2000mm (customizable) |

| Working Width | 600mm / 1000mm / 1300mm |

| Material Compatibility | Stainless Steel, Aluminum, Carbon Steel |

| Dry/Wet Sanding | Optional Wet Sanding System |

| Deburring Function | Top / Bottom Edge Deburring |

| Polishing Grade | #60 to #800 grit belts, optional scotch pad |

| Power Supply | 380V, 50Hz, 3 Phase |

| Control System | Touchscreen PLC + Emergency Stop |

| Safety Features | Dust Collector / Water Circulation / Sensors |

Conclusion

Whether you’re polishing stainless steel, grinding aluminum sheets, or deburring laser-cut metal parts, our metal belt sander machines offer unmatched performance and reliability. Backed by cutting-edge technology and engineered for industrial use, they are the perfect solution for achieving top-quality metal surface finishing and wet sanding.

👉 Contact us today for a personalized quote or to learn more about our full range of metal sanding equipment.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao