Improving Weld Joint Flatness and Smoothness with Metal Sanders

It helps remove defects, oxide layers, slag, and uneven areas created during the welding process, thereby enhancing the quality of the weld joint. Here are the specific steps and methods:

Table of Contents

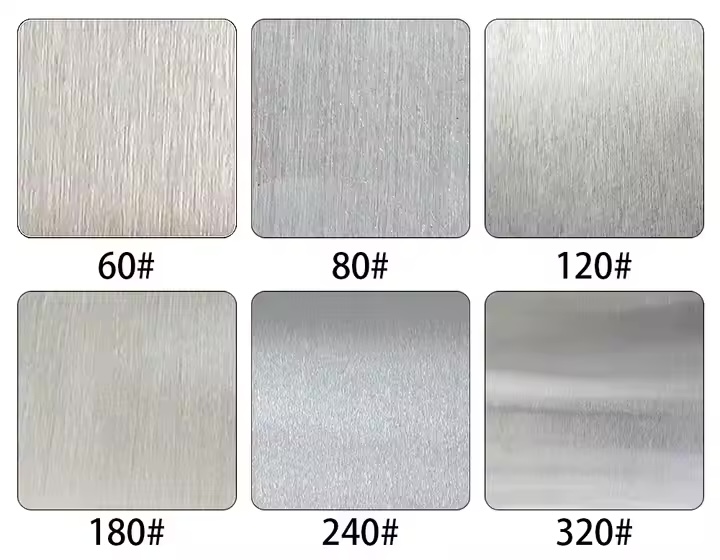

Choose the Right Sanding Machine and Sanding Belts

- Flat Sanding Machine: For improving the flatness of the weld joint, a flat sanding machine is commonly used. Choosing the appropriate sanding belt (coarse, medium, or fine grit) helps progressively remove high spots and flatten the surface.

- Belt Sanding Machine or Cylindrical Sanding Machine: These are suitable for large weld joints or more complex curved surfaces. Belt sanders are ideal for large-area grinding, while cylindrical sanders are better for high-precision sanding of curves and details.

Adjust Sanding Machine Parameters

- Grinding Pressure: Adjust the sanding machine‘s pressure to ensure even contact between the sanding belt and the weld joint. Too much pressure can damage the surface, while too little pressure may not remove enough material.

- Speed Control: Depending on the grit of the sanding belt and the processing requirements, adjust the sanding machine’s speed. Higher speeds help remove raised areas on the weld joint quickly, while lower speeds are better for fine sanding to ensure flatness and smoothness.

Workload and Ease of Operation

- Metal Sanding Machines: Sanding machines can run continuously, reducing the physical labor of manual operation. They are relatively easy to operate, requiring only setup and monitoring, which greatly reduces operator fatigue, especially during long working hours.

- Traditional Manual Grinding Tools: Manual tools require prolonged physical effort, especially when working with hard metals. The operator may experience hand fatigue, which can affect efficiency and comfort during long grinding sessions.

Gradual Sanding Process

- Coarse Sanding: Start with a coarse-grit sanding belt to remove larger flaws and raised areas on the weld joint, bringing the surface closer to flatness.

- Medium and Fine Sanding: Gradually use medium and fine-grit sanding belts to further refine the surface, removing scratches left by the coarse sanding and making the surface smoother.

- Polishing: For a higher level of smoothness, use a polishing sanding belt or soft pad for the final step, achieving the desired surface gloss on the weld joint.

Regularly Check the Weld Joint

During the sanding process, regularly check the weld joint’s flatness and smoothness to ensure that each sanding stage meets the requirements. If significant unevenness or low spots are found, additional sanding may be necessary.

Post-Treatment and Cleaning

After sanding and polishing, clean the weld joint to remove any remaining sand particles or metal debris. Use air or a cleaning agent to ensure the surface is clear of contaminants, achieving the final surface quality.

Conclusion

By properly using a metal sanding machine and selecting the appropriate sanding belts and processes, you can effectively improve the flatness and smoothness of weld joints. Fine control throughout the sanding process helps eliminate welding defects and enhances both the appearance and mechanical properties of the weld joint.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

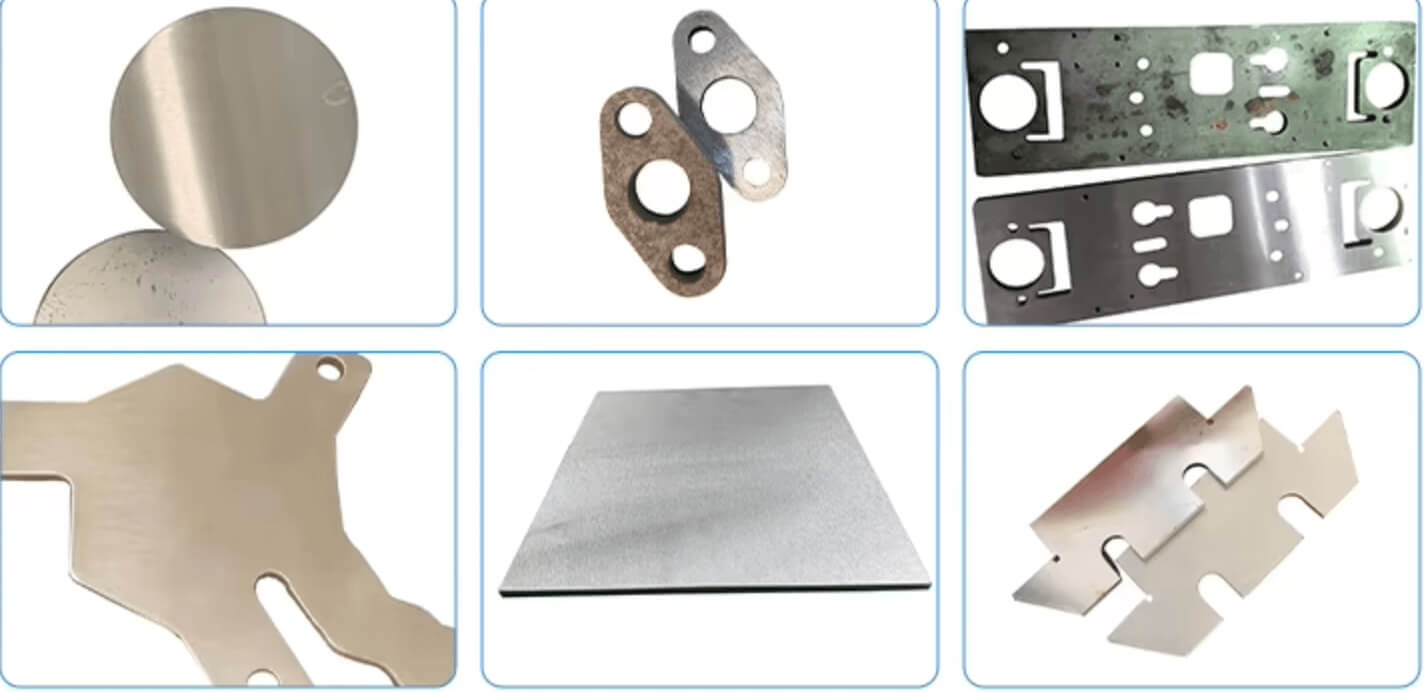

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao