How SMEs Can Choose a Cost-Effective Metal Sanding Machine

For small and medium-sized enterprises (SMEs), selecting a cost-effective metal sanding machine can not only enhance production efficiency but also ensure product quality. However, with numerous types of machines available in the market at varying price points, choosing the right one within a limited budget can be a challenge. This article will provide key factors SMEs should consider when purchasing a high-cost-performance metal sanding machine, helping them make an informed decision without exceeding their budget.

Table of Contents

Define Requirements and Priorities

Before selecting a metal sanding machine, it is essential to define the specific needs. Given the budget constraints, companies can prioritize features that best fit their production requirements. For instance:

- Material Type and Size: Identify the primary metal materials to be processed (e.g., stainless steel, aluminum, iron, etc.) and the size of the workpieces.

- Surface Finish Requirements: If high surface quality is required, choose machines that offer higher precision and uniformity. For less critical surface finishes, a simpler and more affordable model may suffice.

- Production Volume: Select a machine that matches the expected production volume, avoiding over-specifying the machine’s capabilities and increasing unnecessary costs

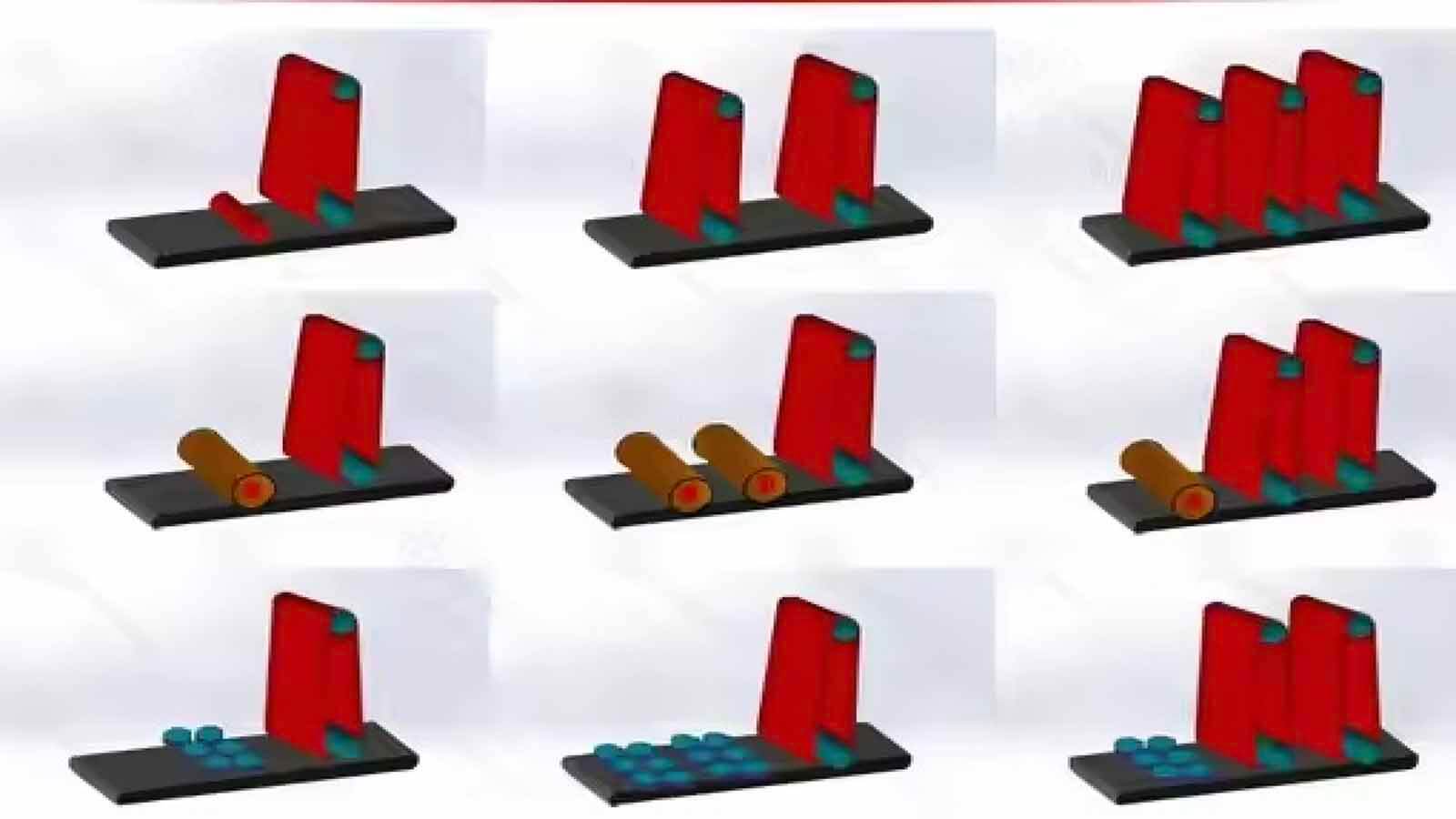

Choose the Right Type of Sanding Machine

SMEs can choose a machine type based on their specific needs. Different types of sanding machines are suitable for different tasks, and selecting the right one can save costs:

- Belt Sanders: Suitable for high-volume metal surface polishing, offering good efficiency and cost performance.

- Flat Sanders: Ideal for precise surface processing, perfect for tasks requiring higher accuracy.

- Vertical Sanders: Suitable for small batch production or parts finishing, offering lower cost, making it a good fit for SMEs.

Focus on Machine Performance and Durability

Balancing performance and durability is essential when working within a limited budget. Opting for machines from reputable brands ensures higher reliability and longer service life, which can reduce maintenance costs over time. Avoid selecting very cheap but unreliable machines, as these may affect production efficiency and incur higher repair costs.

- Choose Well-Known Brands: Established brands typically offer more reliable and durable machines, and while the initial investment might be slightly higher, they provide better long-term value.

- Assess Machine Quality: Pay attention to critical components, such as motors, sanding belt systems, and sanding heads, ensuring they are robust and durable.

Consider Second-Hand or Refurbished Equipment

If the budget is tight, purchasing second-hand or refurbished sanding machines can be a cost-effective alternative. Many used machines are professionally refurbished and can still deliver excellent performance at a fraction of the price of new ones. When buying used equipment, choose a reputable supplier and ensure the machine has been thoroughly inspected and tested before purchase.

Evaluate Financing Options and Payment Plans

- Installment Payments or Leasing: Many suppliers offer installment payment plans or leasing options, which can help reduce the initial financial burden.

- Government Subsidies or Loans: Some local governments or industry associations provide subsidies or low-interest loans for equipment purchases. SMEs can explore these options to ease the financial pressure.

Conclusion

For small and medium-sized enterprises, purchasing a cost-effective metal sanding machine within a limited budget is a critical decision. By defining clear requirements, choosing the right machine type, focusing on performance and durability, considering maintenance costs, and exploring financing options, companies can make more informed purchasing decisions. Ultimately, making the right investment will not only enhance production efficiency but also ensure high-quality products, allowing SMEs to stay competitive in the marketplace.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao