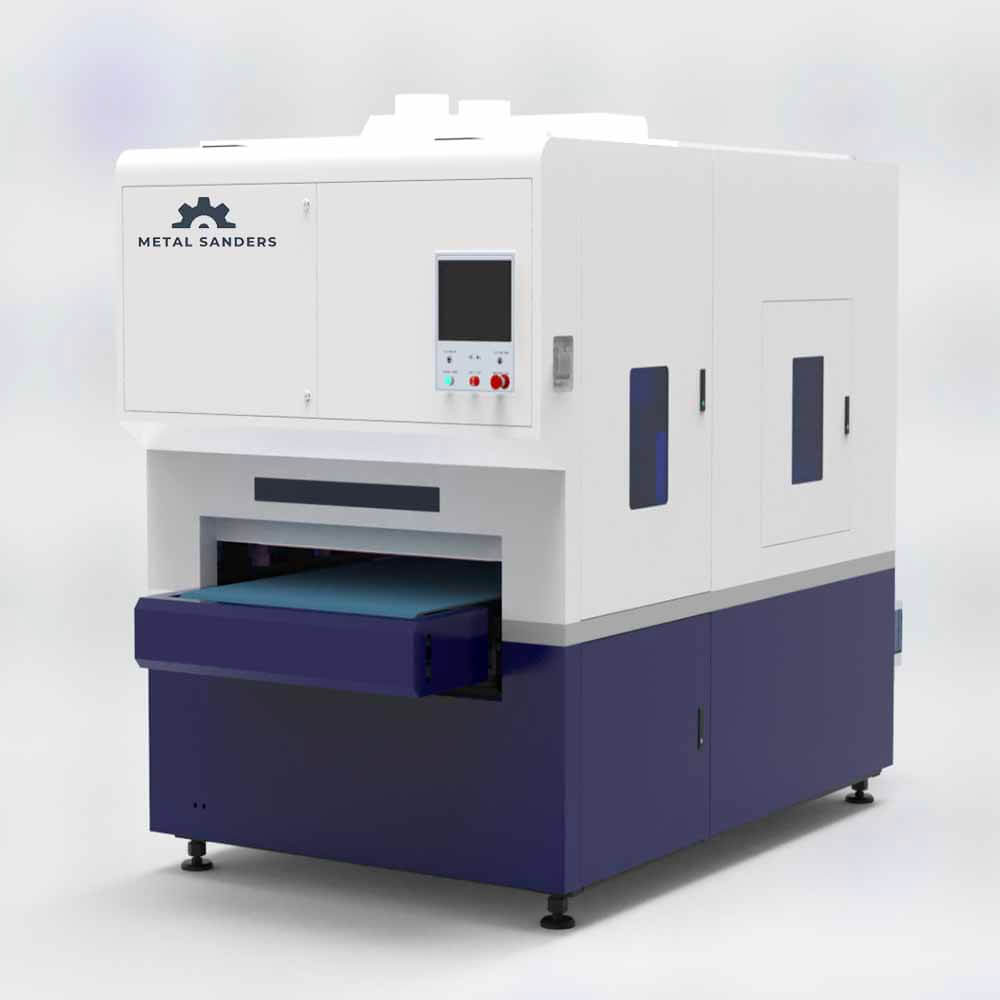

High Precision Wide Belt Sander Machine for Metal Composite Finishing

Whether you’re working with sheet metal, composite boards, or stainless steel, this powerful industrial metal sander delivers consistent, high-quality finishes that meet the demands of modern fabrication.

As a trusted metal sanding machine manufacturer, we design every unit to meet the requirements of heavy-duty environments, offering versatility across applications such as laser-cut part deburring, brushed finishing, and oxide removal. It’s a perfect solution for customers seeking a reliable sheet metal finishing machine that handles everything from light finishing to aggressive stock removal.

Table of Contents

Key Features of the Wide Belt Sander Machine – Ideal for Metal and Composite Materials

- Reinforced Frame for Stability

The machine’s heavy-duty frame ensures stable and precise sanding on both metal and composite workpieces, minimizing vibration and improving accuracy. - Abrasive Belt Sanding System

Equipped with a durable abrasive belt system for polishing and finishing, this wide belt sander machine can handle everything from coarse to fine finishes on stainless steel and composite material. - Touchscreen PLC Interface

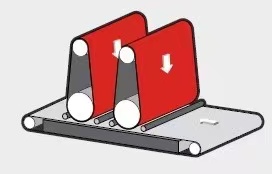

Intuitive control via touchscreen allows for programmable sanding sequences and real-time adjustments, perfect for batch production. - Multi-Head Sanding Stations

Dual or triple sanding heads allow progressive grinding, smoothing, and polishing steps—ideal for a high-end composite material sanding machine. - Dust Collection and Safety Features

Advanced dust extraction ports and safety sensors ensure a clean and safe operating environment, extending belt life and machine longevity. - Customizable Specifications

Available in various belt sizes and motor configurations to meet your specific finishing needs for flat panels or shaped components.

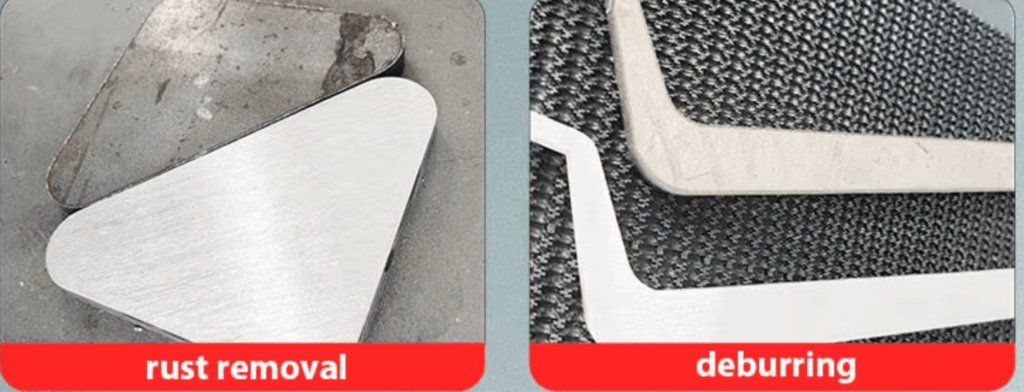

Applications

This metal sanding machine is perfectly suited for:

Sheet metal finishing – brushed or polished surfaces on stainless steel, aluminum, copper, etc.

Composite panel sanding – smooth decorative boards, aluminum composites, and synthetic materials.

Laser/plasma-cut edge deburring – removes sharp edges and oxidation from cut parts.

These capabilities make it an ideal stainless steel sander and sheet metal finishing machine for metal fabrication shops, furniture panel manufacturers, elevator factories, and stainless steel processing plants.

Technical Specifications

| Parameter | Value |

|---|---|

| Working Width | 1000mm / 1300mm / 1600mm |

| Workpiece Thickness | 0.5mm – 100mm |

| Sanding Belt Size | 1330mm × 2200mm (customizable) |

| Motor Power | 30kW – 45kW |

| Conveyor Speed | 5 – 30 m/min |

| Voltage | 380V / 50Hz / 3-Phase |

| Control System | PLC + Touchscreen |

| Machine Weight | 3000 – 4500kg |

Why Choose This Industrial Metal Sander?

- Boost Productivity – Multiple sanding stages in one pass reduce downtime and manual labor.

- Consistent Results – Achieve uniform finishing across a wide variety of materials.

- Versatility – From metal polishing to composite material sanding, this machine adapts to any surface treatment task.

- Reliable Engineering – Designed by a proven wide belt sander machine manufacturer for long-lasting performance.

Whether you need a metal sanding machine for precision polishing or a composite material sanding machine for decorative panels, this unit offers unmatched value.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao