High-Performance 1000MM Metal Sheet Sanding Machine: Wet-Type Abrasive Belt Polishing Solution

The 1000MM Metal Sheet Sanding Machine, a wet-type abrasive belt sander, provides an advanced, reliable solution for polishing, deburring, and finishing metal sheets. Designed for precision and efficiency, this machine is ideal for cutting and stamping parts across various industries.

Table of Contents

Why Choose an Automatic Sheet Metal Polishing and Deburring Machine?

Efficient metal finishing often determines the quality of the final product. The Automatic Sheet Metal Polishing Deburring Machine is engineered to handle a variety of materials, including stainless steel, iron, aluminum, and brass. Its wet-type water grinding system reduces dust, ensuring a safer and cleaner work environment.

Key benefits include:

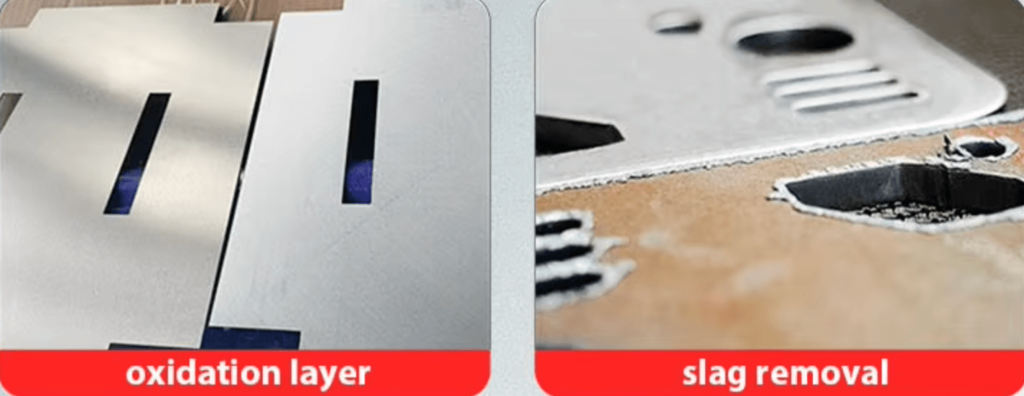

- Precision Deburring: Effectively removes burrs from plasma-cut and stamped metal parts.

- Smooth Finishes: Achieves uniform surface polishing for improved product appeal.

- Wide Belt Design: Accommodates sheets up to 300-1300mm, enhancing versatility.

- Automatic Operation: Reduces manual effort and enhances production efficiency.

Features of the Wide Belt Sander for Sheet Metal

The Automatic Metal Sheet Flat Plate Water Grinding Sanding Polishing Machine is designed for durability, consistency, and adaptability. Its robust construction and advanced features ensure a superior sanding process for sheet metals.

Key Features:

- Adjustable Abrasive Belt System: Ensures compatibility with various surface roughness requirements.

- Water-Based Cooling Mechanism: Prevents overheating, reduces sparks, and extends the lifespan of abrasive belts.

- Wide Belt Capacity: Handles metal sheets ranging from 300mm to 1300mm, making it versatile for different sizes and shapes.

- Flat Plate Polishing: Provides excellent results on flat metal surfaces, enhancing smoothness and shine.

- Automatic Feed System: Allows continuous operation for high-volume production lines.

This machine is a perfect choice for applications requiring a combination of deburring and surface finishing in one seamless process.

Applications of the Wet-Type Abrasive Belt Sanding Machine

The Wide Belt Sander is widely used in industries such as:

- Metal Fabrication: For deburring and finishing plasma-cut or laser-cut parts.

- Automotive: Polishing and preparing metal sheets for painting or assembly.

- Appliances: Enhancing the surface finish of stainless steel panels.

- Construction: Smoothing and polishing flat plates for architectural applications.

Conclusion: A Versatile Solution for Metal Finishing

The 1000MM Metal Sheet Sanding Machine delivers exceptional performance, combining precision, efficiency, and safety. Whether you’re working on cutting, stamping, or polishing projects, this Automatic Metal Sheet Flat Plate Water Grinding Sanding Polishing Machine is a reliable partner. With its wide belt sander capabilities and wet-type abrasive belt system, it caters to a range of metal finishing tasks, ensuring superior quality and consistent results.

Upgrade your metalworking process with this versatile machine and experience the difference in productivity and precision.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao