High Efficiency Metal Polishing and Sanding Machines

In this article, we focus on three essential keywords: Polishing Machine, Metal Polishing Machine, and Sanding Machine. Let’s explore their functions, benefits, and how to select the best machine for your specific application.

Table of Contents

What Is a Polishing Machine?

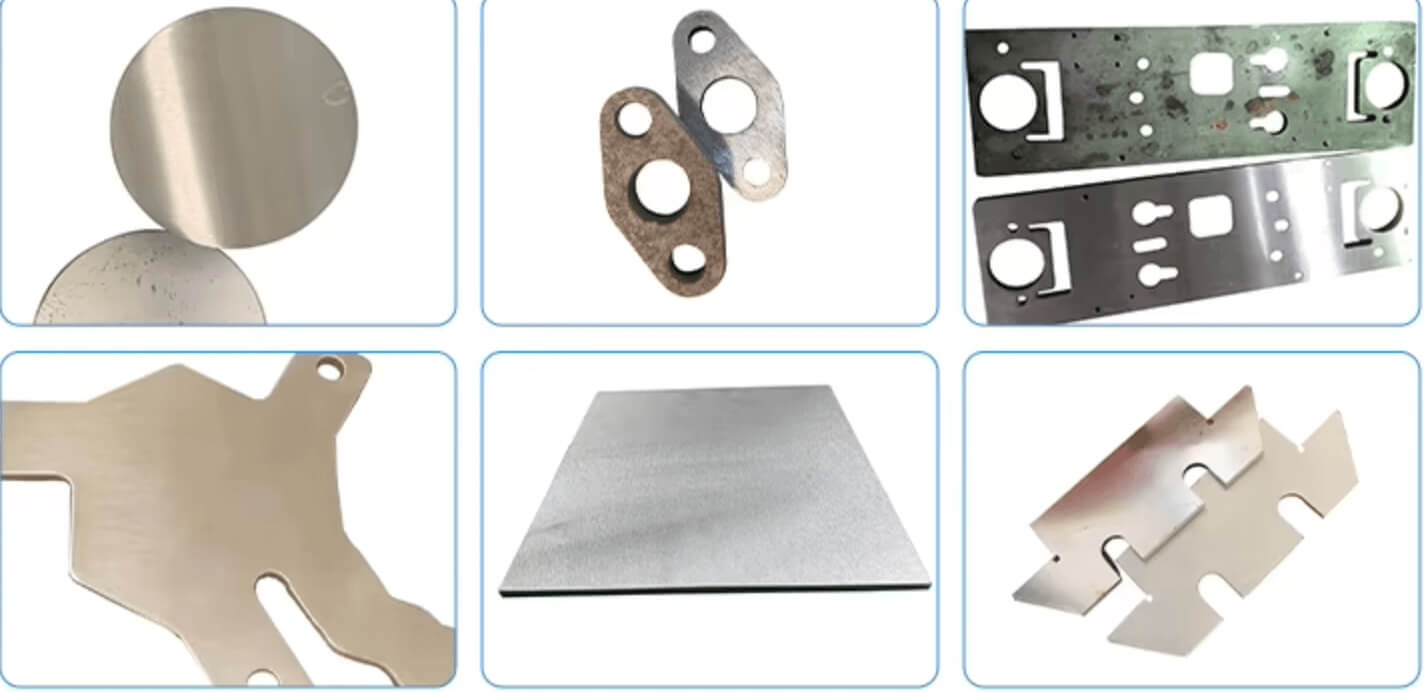

A Polishing Machine is designed to smooth and refine metal surfaces by removing burrs, weld marks, oxidation, and scratches. It plays a key role in achieving a flawless finish on stainless steel, aluminum, brass, and iron products. Whether you’re producing in bulk or handling precision parts, polishing machines deliver outstanding surface results.

Key Advantages:

High polishing speed: Quickly removes imperfections from the metal surface

Consistent finish: Ensures uniform quality across all parts

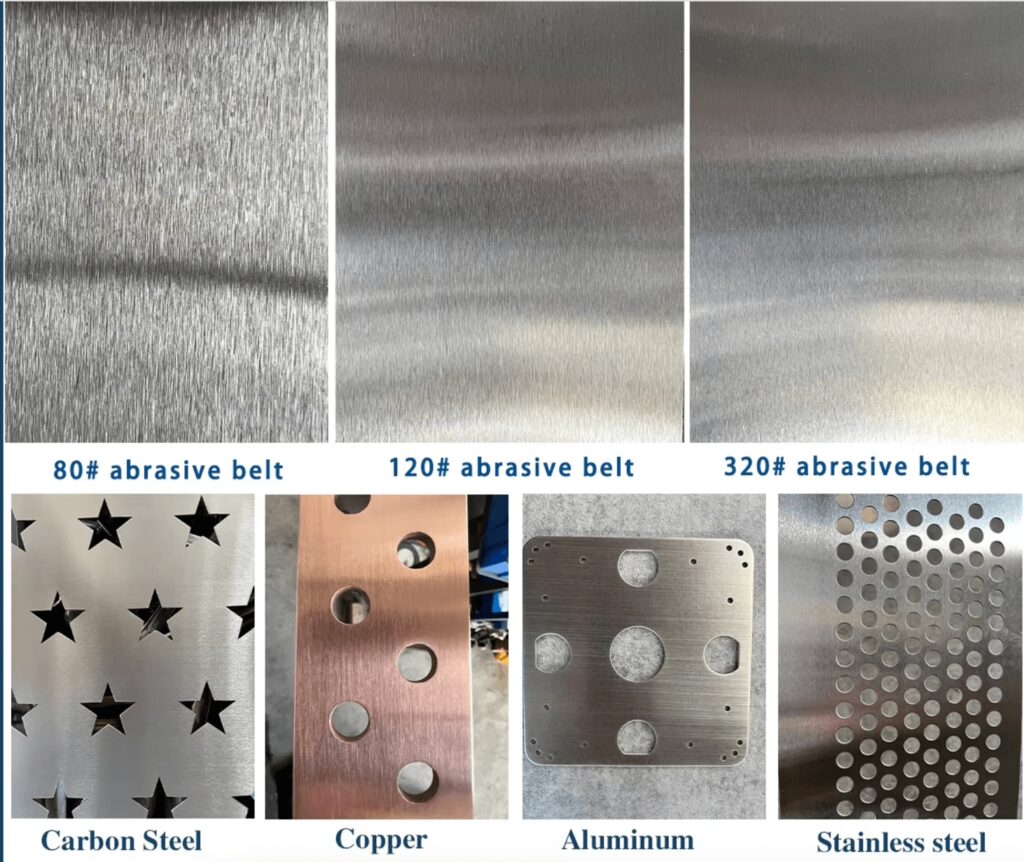

Multi-material compatibility: Suitable for stainless steel, aluminum, copper, and more

Flexible configurations: Available in single-head, double-head, and multi-axis designs

The Industrial Value of a Metal Polishing Machine

Compared to manual tools, a Metal Polishing Machine offers greater stability, speed, and durability. It’s widely used in industries such as kitchenware, sheet metal, auto parts, hardware, and lighting to enhance surface brightness and product aesthetics.

Core Capabilities:

▶ Deburring and edge rounding: Smooths sharp edges after cutting or welding

▶ Mirror finish polishing: Creates a reflective, high-gloss surface

▶ Customizable with various abrasives: Works with sanding belts, flap wheels, scouring pads, and more

Sanding Machines: The Foundation of Metal Surface Treatment

A Sanding Machine is essential for the initial surface preparation of metal components. It’s ideal for removing rust, flattening weld seams, and preparing surfaces for subsequent polishing or coating processes.

Recommended Applications:

Pre-polishing for stainless steel panels

Post-weld surface leveling

Aluminum and copper component preparation

DIY metal projects and small-batch production

How to Choose the Right Polishing or Sanding Machine

To select the most suitable Polishing Machine or Sanding Machine, consider the following:

Material type: Different machines are optimized for stainless steel, aluminum, iron, etc.

Workload and production scale: For continuous or industrial production, consider automated or multi-head systems

Surface treatment goal: Rough grinding, satin finish, or mirror finish? Choose the right grade and configuration

Dust control: Machines with built-in dust extraction protect workers and extend machine life

Why Choose Us?

We are a professional manufacturer specializing in metal surface treatment machines, offering a full range of Polishing Machines, Metal Polishing Machines, and Sanding Machines trusted by customers worldwide.

We Promise:

Factory-direct pricing with excellent cost-performance ratio

100% original, high-quality machines

Fast global shipping

Technical support and professional consultation

Custom solutions for your specific industry needs

1000mm Metal Sanders Machine Specifications

Our 1000mm wide sanding machine is specially designed for medium to large-format metal sheets and components, delivering precise and efficient surface finishing.

| Specification | Details |

|---|---|

| Model | MS-1000W |

| Working Width | 1000mm |

| Working Thickness | 0.5 – 80mm |

| Abrasive Belt Size | 1900 x 1000mm |

| Feeding Speed | 5–25 m/min adjustable |

| Main Motor Power | 11 kW |

| Feeding Motor Power | 1.5 kW |

| Cooling System | Water spray & dust extraction |

| Voltage | 380V / 50Hz 3Phase |

| Application | Stainless steel, aluminum, iron |

| Optional Features | Dry/wet modes, brush rollers |

This model supports both wet and dry sanding, making it ideal for finishing metal plates used in cabinets, elevators, decorative panels, and more.

Conclusion

Investing in a high-quality Polishing Machine, Metal Polishing Machine, or Sanding Machine is not just a purchase—it’s a long-term upgrade to your production process. With the 1000mm metal sander’s robust build and customizable features, you can handle a wide variety of jobs with unmatched consistency and efficiency.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao