Heavy-Duty Sander Machine for Metal: Efficient Sheet Metal Finishing & Deburring Solutions

Our advanced metal sanding equipment is engineered to meet the demands of modern manufacturing, combining high-speed performance, automation, and precision for a superior finishing experience.

Whether you’re processing aluminum, stainless steel, carbon steel, or composite panels, our sheet metal finishing machine offers reliable, efficient, and repeatable results.

Table of Contents

Key Features of the Metal Sanding Equipment + Deburring Machine

Heavy-Duty Wide Belt Sander for Flat Plate Grinding

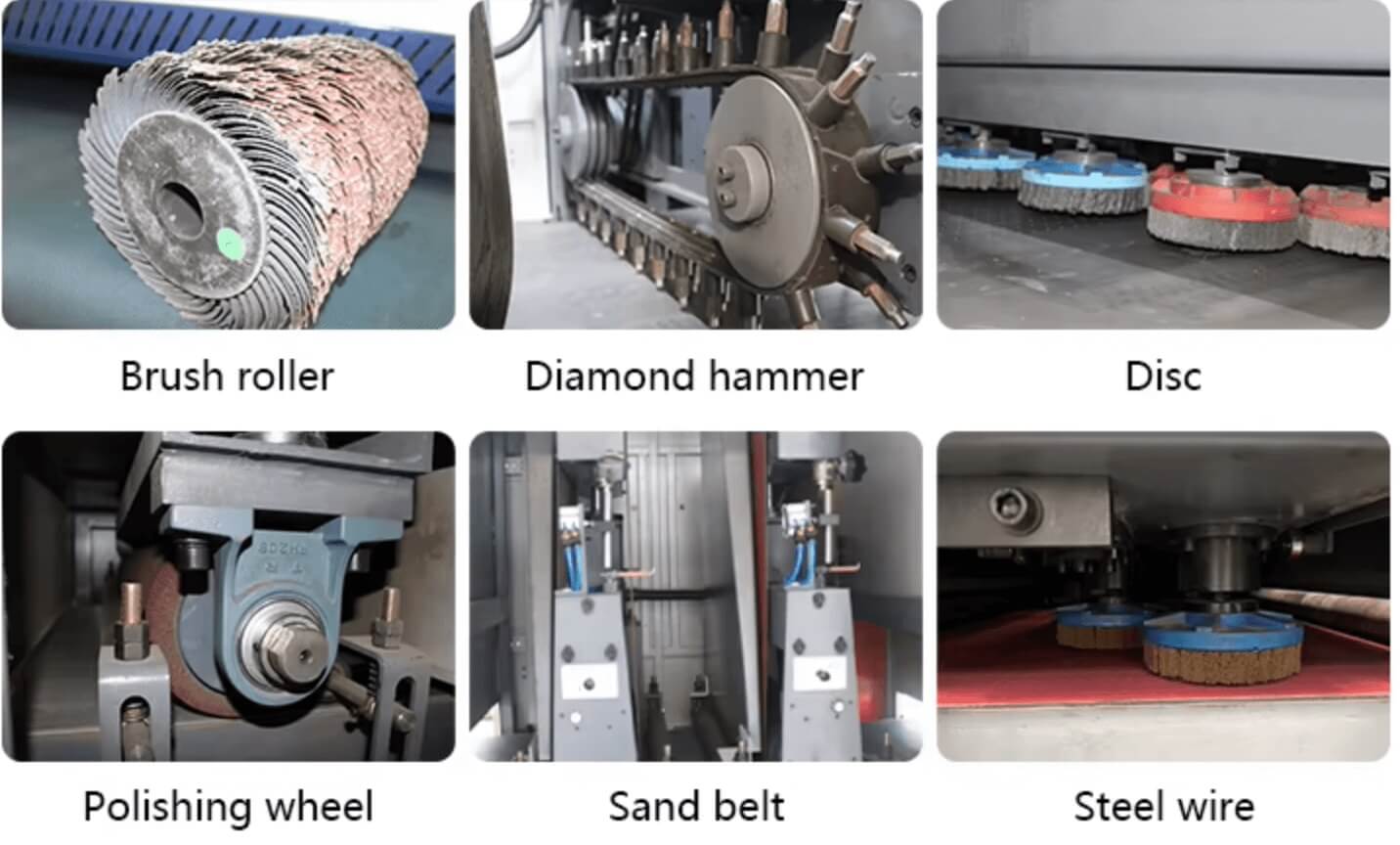

Built with industrial-grade components, our wide belt sander provides consistent and even grinding for sheet metal surfaces, especially ideal for flat plate grinding and smoothing weld seams.Integrated Deburring Machine Functionality

This machine eliminates sharp edges and burrs created during laser cutting, punching, or shearing, making it a high-efficiency deburring machine for all types of metals.CNC Sander with Programmable Precision

Featuring a user-friendly CNC control panel, our CNC sander allows programmable speed, pressure, and feed rate, enabling uniform results with minimal manual intervention.Multi-Stage Surface Polishing Machine for Superior Finish

Equipped with abrasive belts and polishing rollers, this surface polishing machine is suitable for satin finishing, brushing, and mirror polishing of metal sheets.Adjustable Pressure and Feed Rate

Handle varying material thicknesses and hardness levels by customizing settings based on your job requirements.Dust Collection and Safety System

Designed with industrial workshops in mind, this industrial polisher includes a dust removal system and emergency stop features for operator safety and clean environments.

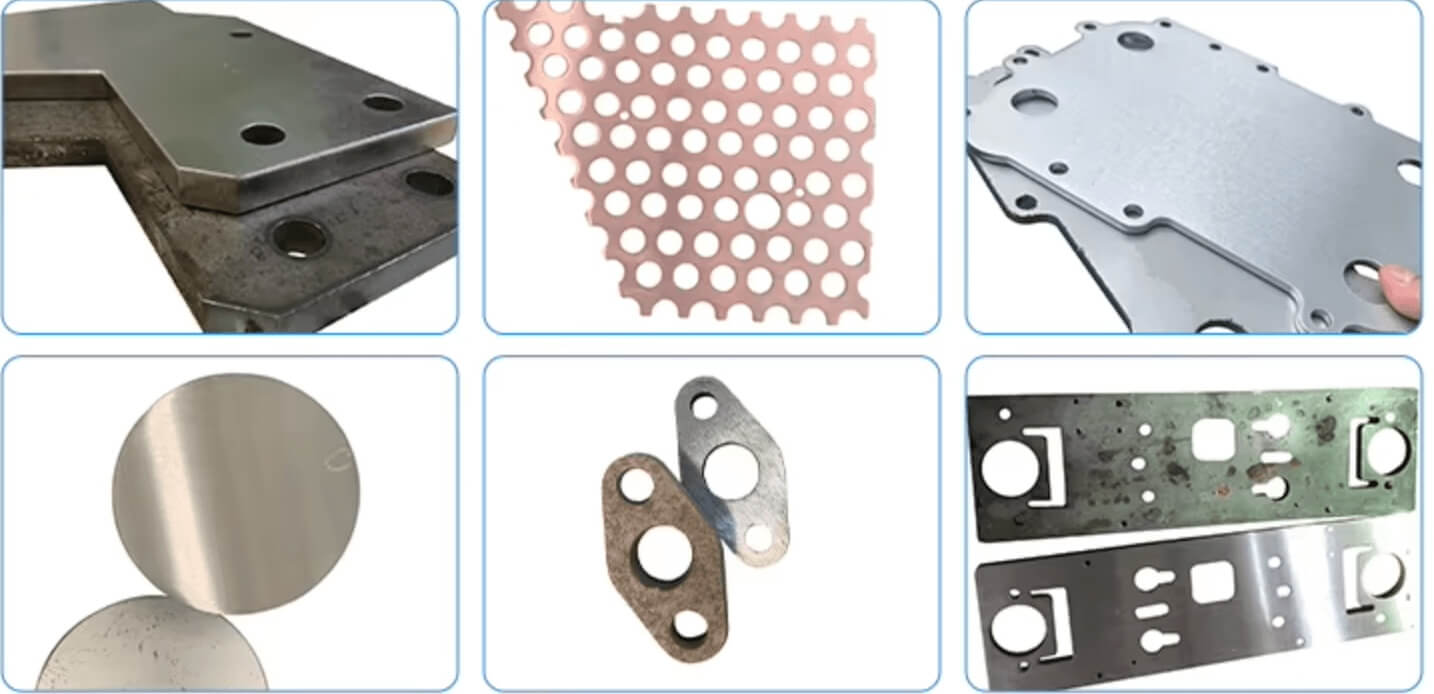

Applications

This sheet metal finishing solution is ideal for:

Laser-cut and plasma-cut metal parts

Stainless steel surface polishing and deburring

Aluminum and mild steel flat sheet sanding

Finishing architectural panels and signage backplates

Fabrication shops, commercial kitchens, elevator panels, and more

These diverse capabilities make it a must-have for manufacturers in search of a high-performing metal sanding equipment and sheet metal finishing machine.

Technical Specifications

| Parameter | Value |

|---|---|

| Working Width | 600mm / 1000mm / 1300mm |

| Belt Speed | 5–25 m/min (adjustable) |

| Belt Size | 1900 × 130mm |

| Motor Power | 11kW – 22kW (customizable) |

| Voltage | 380V / 50Hz |

| Pressure Adjustment | Pneumatic + Electric Control |

| Control Interface | Touchscreen CNC |

| Dust Collector Interface | Yes |

Why Choose This CNC Sander Machine for Metal?

Boost Productivity – Automate surface finishing and reduce labor time

Improve Product Quality – Consistent polishing, sanding, and deburring with minimal defects

Versatile Processing – Works with stainless steel, carbon steel, aluminum, and copper

Low Maintenance – Durable design reduces downtime and part replacements

Eco-Friendly – Optional water mist and vacuum systems available

With this industrial-grade CNC sander and industrial polisher, your production line gains the power to meet demanding finishing standards with confidence.

Conclusion

If you’re looking for a reliable, high-efficiency sander machine for metal, our industrial-grade equipment offers the perfect balance of precision, durability, and performance. Whether you’re handling sheet metal finishing, deburring, flat plate grinding, or surface polishing, our CNC sander and metal sanding equipment provide consistent results across a wide range of metal materials. With smart automation and rugged construction, this is the ultimate solution for any manufacturer aiming to upgrade their metal surface finishing machine lineup.

Ready to elevate your production quality? Contact us today for a free quote or live demo!

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao