Enhancing Product Quality: Sanding Empowers Laser Cutting

However, to further enhance product quality, sanding machines have become an essential auxiliary tool in the laser cutting process.

Table of Contents

The Perfect Combination of Laser Cutting and Sanding

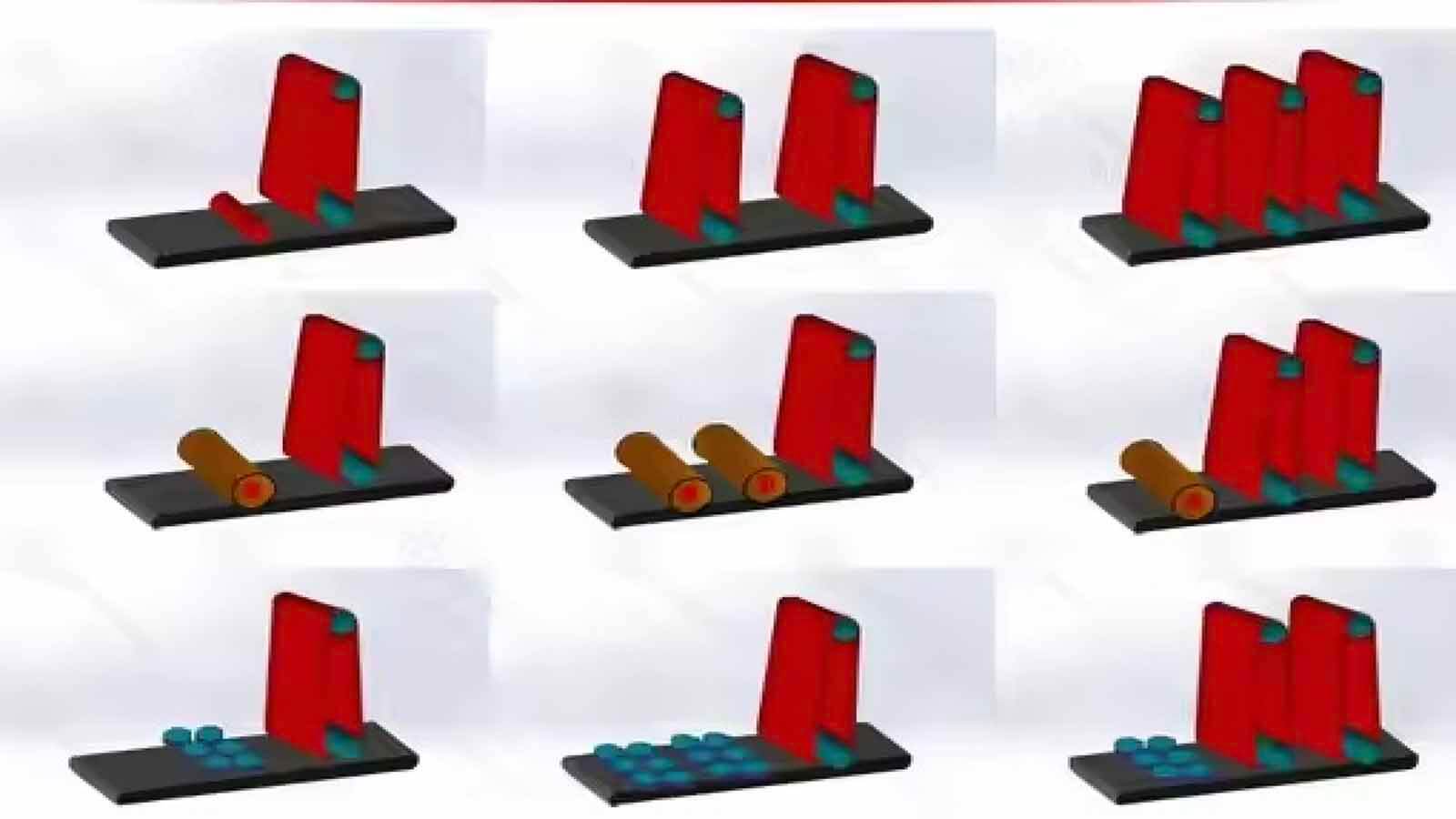

While laser cutting achieves intricate patterns and high precision, it can leave behind burrs, oxide layers, or rough edges on the metal surface. These imperfections can affect both the appearance of the product and subsequent processes like painting or plating.

Sanding machines efficiently remove burrs and oxide layers while polishing the surface. This significantly improves the smoothness and flatness of the metal, providing a flawless finish for laser-cut components.

Advantages of Sanding Machines in Metal Processing

- Versatility: Suitable for various metal materials, including stainless steel, aluminum, iron, brass, and more.

- High Efficiency: Quickly processes large batches of metal sheets, improving production efficiency.

- Consistency: Ensures uniform surface treatment for every piece, minimizing errors caused by manual operations.

- Eco-friendliness: Equipped with advanced dust collection systems to reduce metal dust, protecting the workplace environment and operator health.

Adding Value to Your Products

Metal products treated with sanding machines boast a smoother, more attractive finish. This not only enhances the product’s added value but also lays a solid foundation for subsequent processes. In industries such as home appliances, automotive, and architectural decoration, the quality of surface treatment directly impacts customer satisfaction and brand image.

Conclusion

The combination of laser cutting and sanding is an indispensable part of modern metal processing. Investing in a high-performance sanding machine not only improves product quality but also helps businesses stand out in a competitive market.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao