Energy-Efficient and High-Performance Design of Metal Sanders

Metal sanding machines, used for surface finishing of metal parts, have evolved significantly with innovations that enhance their performance and energy efficiency. In this article, we will explore how modern metal sanding machines are designed for high efficiency, energy savings, and environmental sustainability.

Table of Contents

High-Efficiency Design:

The core of a high-performing metal sanding machine lies in its efficient design, which is centered around powerful motors and advanced transmission systems. These machines are equipped with energy-efficient motors that reduce power consumption while maintaining optimal sanding performance.

- Energy-Efficient Motors: Modern machines feature motors with improved energy conversion efficiency, allowing them to operate at higher speeds with less electrical power consumption. The use of high-efficiency motors means the machines generate less heat, reducing energy wastage and ensuring consistent operation.

- Advanced Drive Systems: Advanced drive mechanisms, such as variable frequency drives (VFD), help optimize the machine’s performance by adjusting motor speeds according to the workload. This ensures that energy is only consumed when needed, improving both efficiency and performance.

Energy-Saving Features:

The design of modern metal sanding machines is focused on reducing long-term energy consumption, which directly impacts operating costs.

- Reduced Power Consumption: Through innovative engineering, manufacturers have succeeded in reducing energy consumption without compromising on sanding quality. Features such as automatic adjustments to sanding pressure and speed further contribute to energy savings by ensuring that the machine operates at the optimal energy level for each task.

- Efficient Power Management: Many metal sanding machines now include smart control systems that monitor energy use and adjust settings automatically. This helps minimize unnecessary power consumption during idle times or while performing low-intensity tasks.

Environmentally-Friendly Design:

Beyond just saving energy, modern metal sanding machines are designed with environmental concerns in mind. These machines often feature integrated dust collection systems, which capture metal dust and particles generated during sanding.

- Efficient Dust Collection Systems: These machines are equipped with high-efficiency dust collection mechanisms that help reduce the spread of harmful particles in the air. By keeping the workspace cleaner, they improve the health and safety of workers while also reducing the environmental impact of metalworking operations.

- Cleaner Air Quality: With better filtration systems, the machines contribute to improved air quality in the workshop or production environment. The reduction of airborne contaminants helps create a safer and more comfortable working atmosphere.

Long-Term Benefits of Efficiency and Energy-Saving Designs:

The long-term benefits of energy-efficient and environmentally friendly metal sanding machines are substantial:

- Cost Reduction: Reduced power consumption leads to lower energy costs for businesses. Over time, this translates to significant savings on energy bills, which is particularly important for companies with large-scale sanding operations.

- Lower Maintenance Costs: Efficient machines generate less heat, reducing the wear and tear on critical components. This not only extends the lifespan of the equipment but also reduces the frequency and cost of repairs and maintenance.

- Increased Equipment Longevity: With optimized energy use, better heat management, and advanced components, these machines are built to last longer, offering greater value over their lifetime.

Conclusion

Modern metal sanding machines are designed with high efficiency and energy-saving features that not only enhance performance but also provide long-term environmental and financial benefits. By incorporating energy-efficient motors, advanced drive systems, and dust collection systems, these machines help businesses reduce operating costs, improve air quality, and minimize their environmental footprint. Investing in these advanced machines allows businesses to achieve both economic and ecological sustainability while boosting production efficiency.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

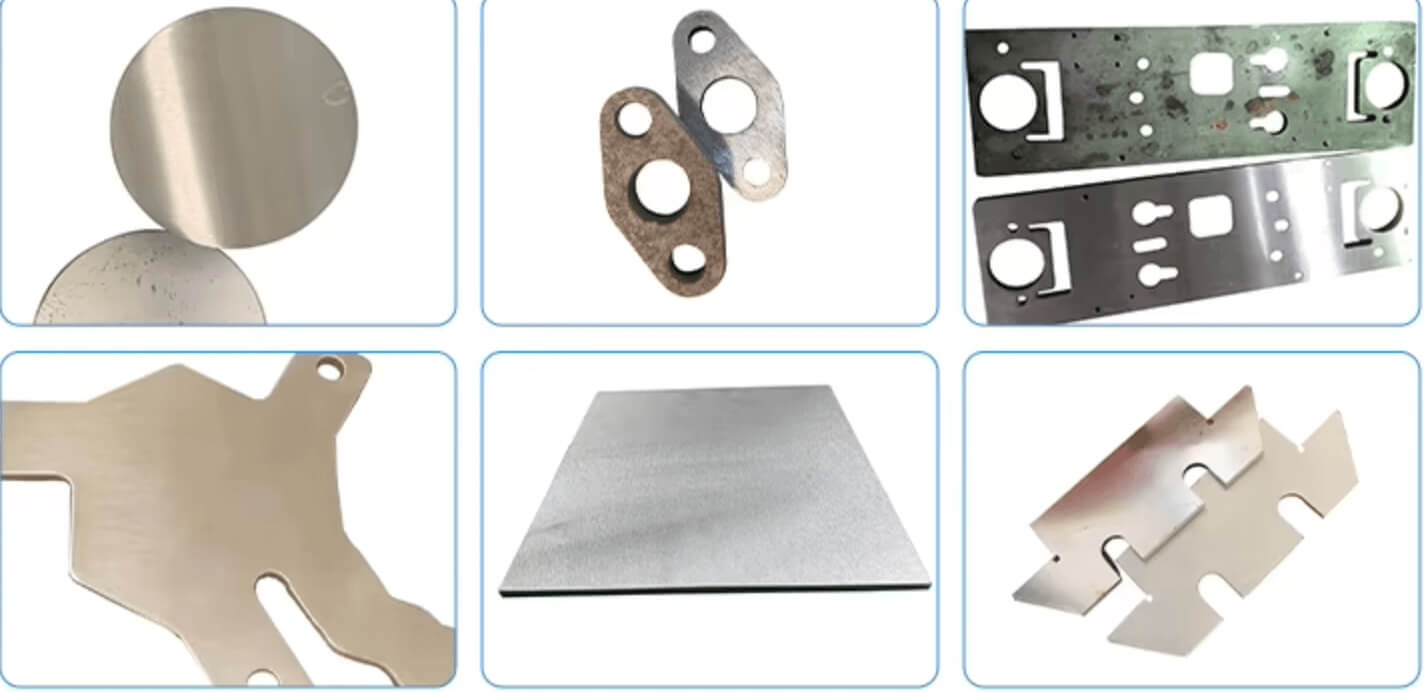

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao