Diverse Applications of Metal Sanding Machines Across Industries

These machines are used in a wide range of industries to remove imperfections, enhance the aesthetic appeal of products, and improve overall quality. In this article, we will explore the diverse applications of metal sanding machines in industries such as stainless steel processing, aluminum alloy cleaning, automotive manufacturing, and electronics production.

Table of Contents

Stainless Steel Processing:

In stainless steel manufacturing, metal sanding machines are used to remove burrs, sharp edges, and oxidation layers from metal surfaces. These machines not only enhance the appearance of stainless steel products but also prepare them for further processing or coating. By smoothing the surface, the sanding machine helps achieve a shiny, polished finish that is crucial for products such as kitchenware, medical devices, and household appliances.

- Applications: Kitchen utensils, cookware, medical equipment, appliances.

- Benefits: Improved surface appearance, reduced burrs and sharp edges, and enhanced corrosion resistance.

Aluminum Alloy Cleaning:

Aluminum alloys are widely used in industries such as aerospace, automotive, and construction due to their lightweight and durable properties. Metal sanding machines effectively remove burrs, smoothen the surface, and eliminate oxidation layers from aluminum parts. This ensures the parts are free of imperfections, improving both their strength and visual quality. The sanding process also enhances the bonding surface for coatings and paints.

- Applications: Aerospace components, automotive parts, construction materials.

- Benefits: Burr removal, oxidation layer removal, smooth surface for further processing.

Automotive Industry:

In the automotive sector, metal sanding machines are vital for surface finishing and quality control of metal components. These machines are used to remove burrs, smooth weld seams, and polish metal parts to achieve both functional and aesthetic requirements. By enhancing the strength and corrosion resistance of components, metal sanding machines contribute to the overall durability and performance of the vehicle. From engine parts to body panels, sanding machines play a significant role in automotive manufacturing.

- Applications: Engine parts, body panels, structural components, exhaust systems.

- Benefits: Enhanced corrosion resistance, improved strength, smooth and polished surfaces.

Electronics Manufacturing:

The electronics industry demands high precision and quality when it comes to metal surfaces used in components like circuit boards, casings, and connectors. Metal sanding machines play a key role in removing solder residues, burrs, and oxidation from electronic parts, improving the performance and aesthetic quality of products. The sanding process helps to achieve a smooth surface, which is essential for proper assembly, connectivity, and reliability in electronic devices.

- Applications: Circuit boards, connectors, casings, and other electronic components.

- Benefits: Removal of solder residues, burr elimination, enhanced surface quality for better performance.

Conclusion

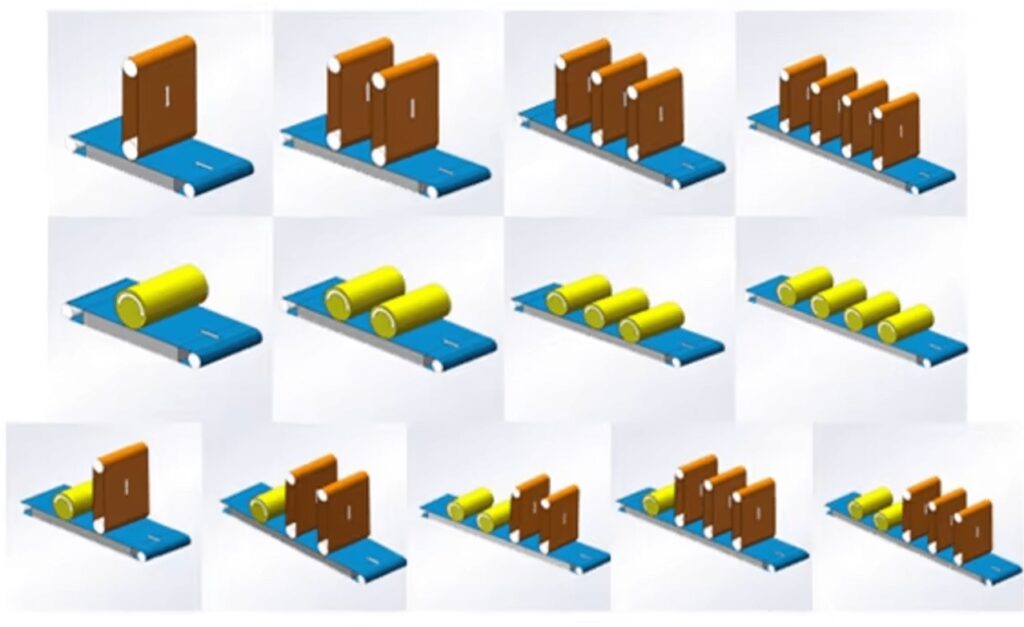

Metal sanding machines are integral to a wide range of industries, offering diverse solutions for surface finishing, deburring, and polishing. Whether in stainless steel processing, aluminum alloy cleaning, automotive manufacturing, or electronics production, these machines ensure that metal parts meet high-quality standards, improving both functional performance and aesthetic appeal. By understanding the specific applications of metal sanding machines in different industries, manufacturers can make informed decisions and optimize their production processes for better results.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao