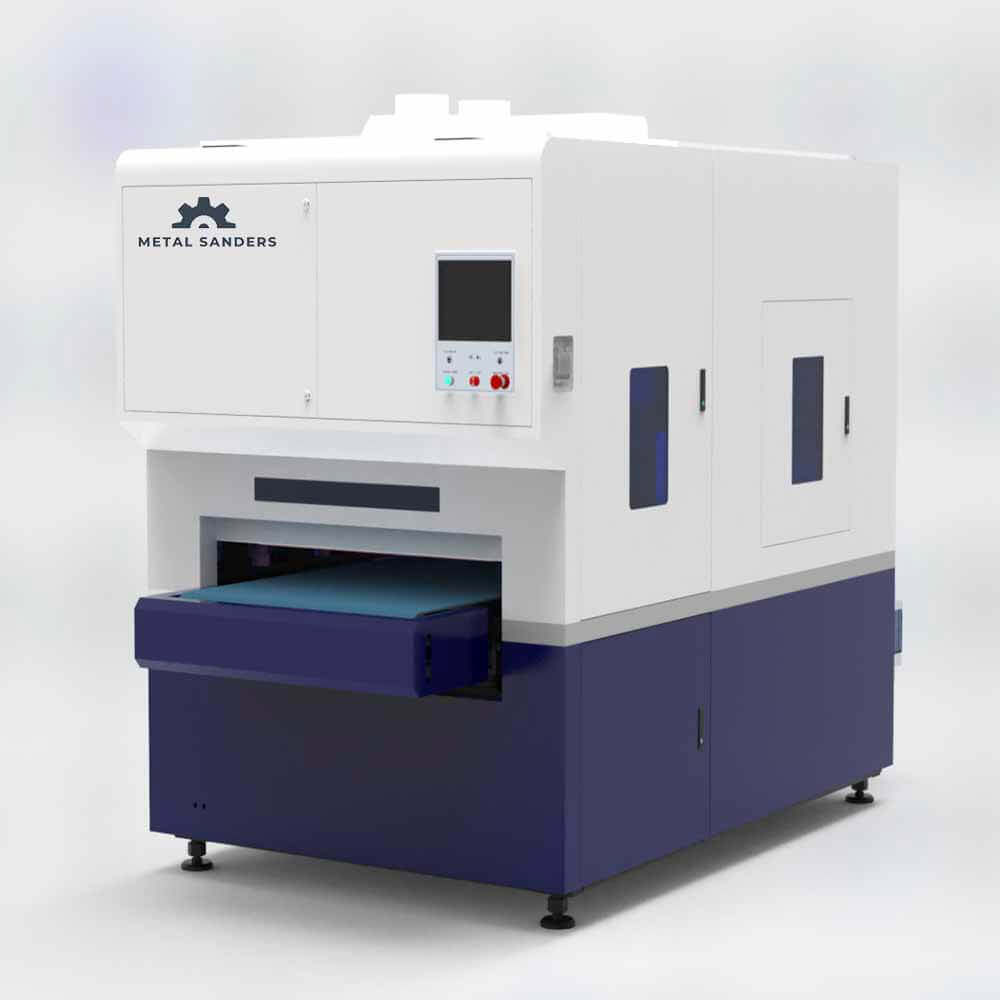

Deburring Sheet Metal Machine: Improve Edge Quality & Surface Safety

A deburring sheet metal machine is essential for manufacturers who want to improve product quality, protect workers, and enhance the appearance and function of metal parts.

This guide introduces the different types of sheet metal deburring machines, their features, and how they add value to metal fabrication operations.

Table of Contents

What Is a Deburring Sheet Metal Machine?

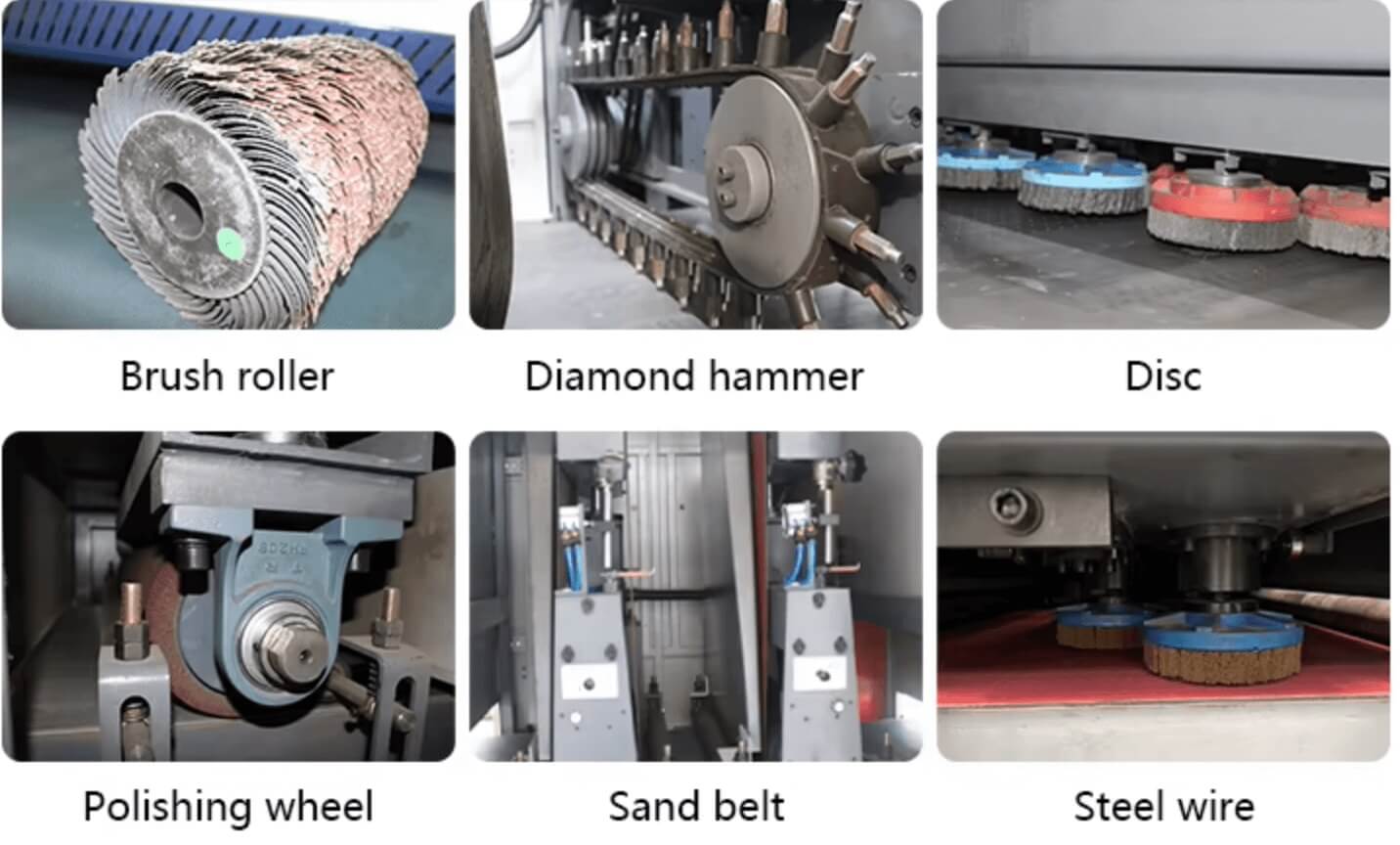

A deburring sheet metal machine is designed to remove burrs, smooth edges, and condition the surface of metal sheets. These machines use tools such as abrasive belts, rotating brushes, or grinding wheels to clean up cut surfaces, leaving them safe, uniform, and ready for downstream processes like welding, coating, or painting.

Benefits of Using a Sheet Metal Deburring Machine

- Improves edge safety by eliminating sharp and dangerous burrs

- Enhances coating adhesion for painting or powder coating

- Prepares surfaces for welding with better joint quality

- Reduces manual grinding time and operator fatigue

- Increases product consistency and surface finish quality

- Prevents defects in assembly and packaging processes

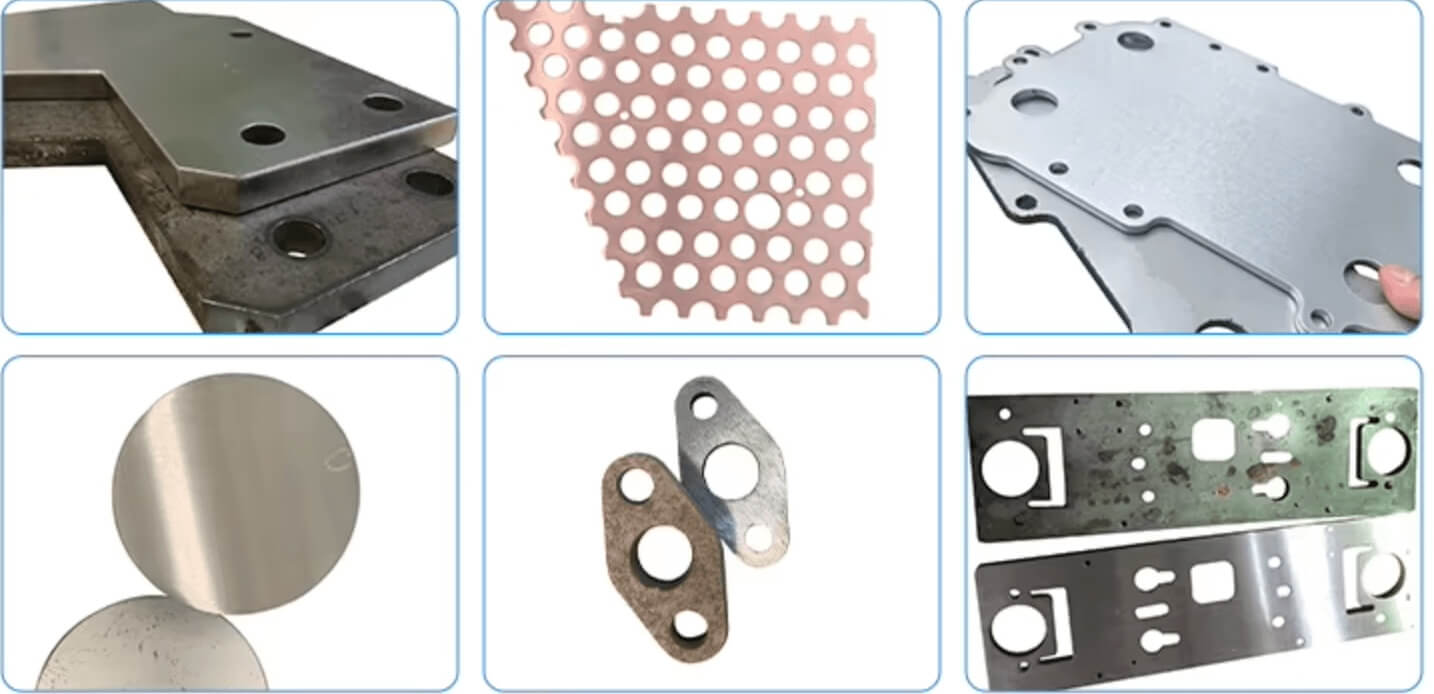

Whether you manufacture electrical enclosures, panels, furniture, or components for the automotive or aerospace industry, these machines boost productivity and quality.

Different Types of Sheet Metal Deburring Machines

When choosing a deburring solution, understanding the machine types is crucial. Here are the most common categories:

1. Abrasive Belt Deburring Machines

These machines use horizontal or vertical sanding belts to remove burrs and slag. Ideal for heavy-duty edge grinding, they are widely used for carbon steel and thick plates.

Best for: Laser-cut or plasma-cut parts with significant burrs.

2. Rotary Brush Deburring Machines

Equipped with rolling or oscillating brushes, these machines are ideal for fine edge rounding and oxide removal—especially for stainless steel and aluminum.

Best for: Surface-sensitive parts and applications requiring uniform edge rounding.

3. Dry Deburring Machines

These systems operate without water or coolant, reducing cleanup and maintenance needs. Dust extraction is usually integrated for a clean work environment.

Best for: General-purpose metal shops and environments with strict cleanliness requirements.

4. Wet Deburring Machines

Wet machines use coolant to suppress dust and cool parts during the deburring process. They produce smoother finishes and extend tool life.

Best for: Polishing or preparing decorative stainless steel parts.

5. Top-and-Bottom Deburring Machines

These automatic systems deburr both sides of the metal sheet in a single pass, significantly increasing throughput and reducing manual flipping.

Best for: High-volume production lines with tight efficiency requirements.

How to Choose the Right Deburring Machine?

When selecting a machine for your shop, consider the following:

- Type and thickness of metal sheets

- Burr size and edge condition after cutting

- Desired finish (rough grind vs. fine polish)

- Throughput requirements (batch or continuous)

- Available workshop space and dust control needs

- Material types (steel, stainless, aluminum, copper)

Investing in the right deburring sheet metal machine saves time, improves safety, and ensures high-quality results in every part.

Conclusion

The right sheet metal deburring machine can transform your production line—reducing manual labor, improving edge quality, and preparing parts for welding, coating, or assembly. By understanding the different types of sheet metal deburring machines, manufacturers can choose the right system for their materials, volume, and finishing needs.

Whether you’re building custom metal enclosures or fabricating large-scale structural components, adding a professional deburring system is a smart, long-term investment.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao