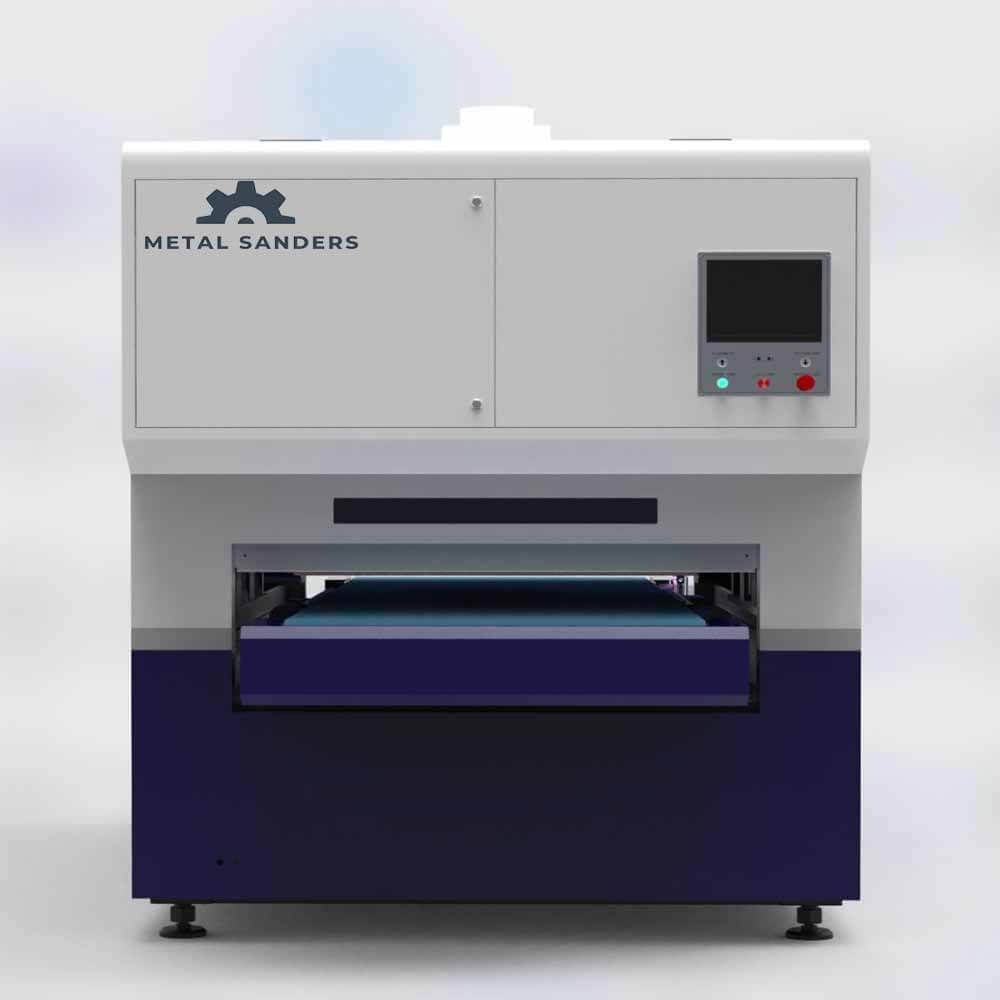

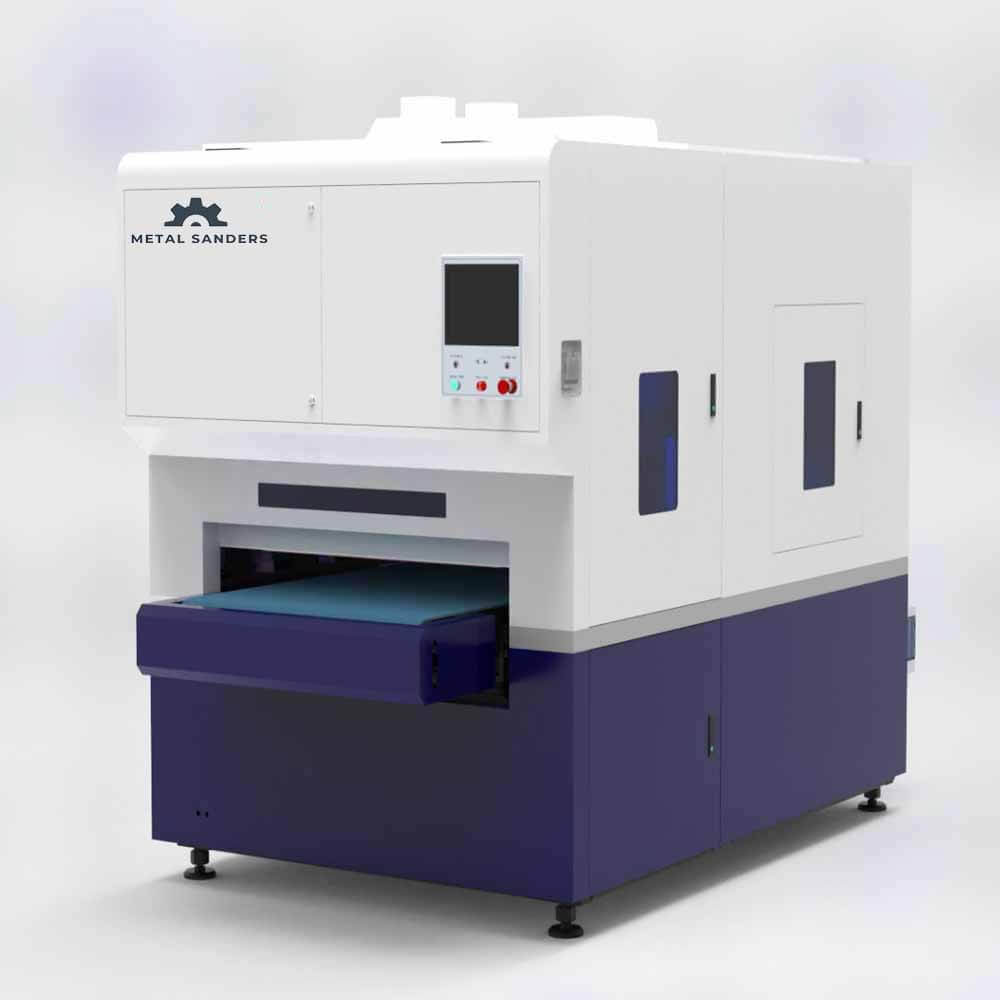

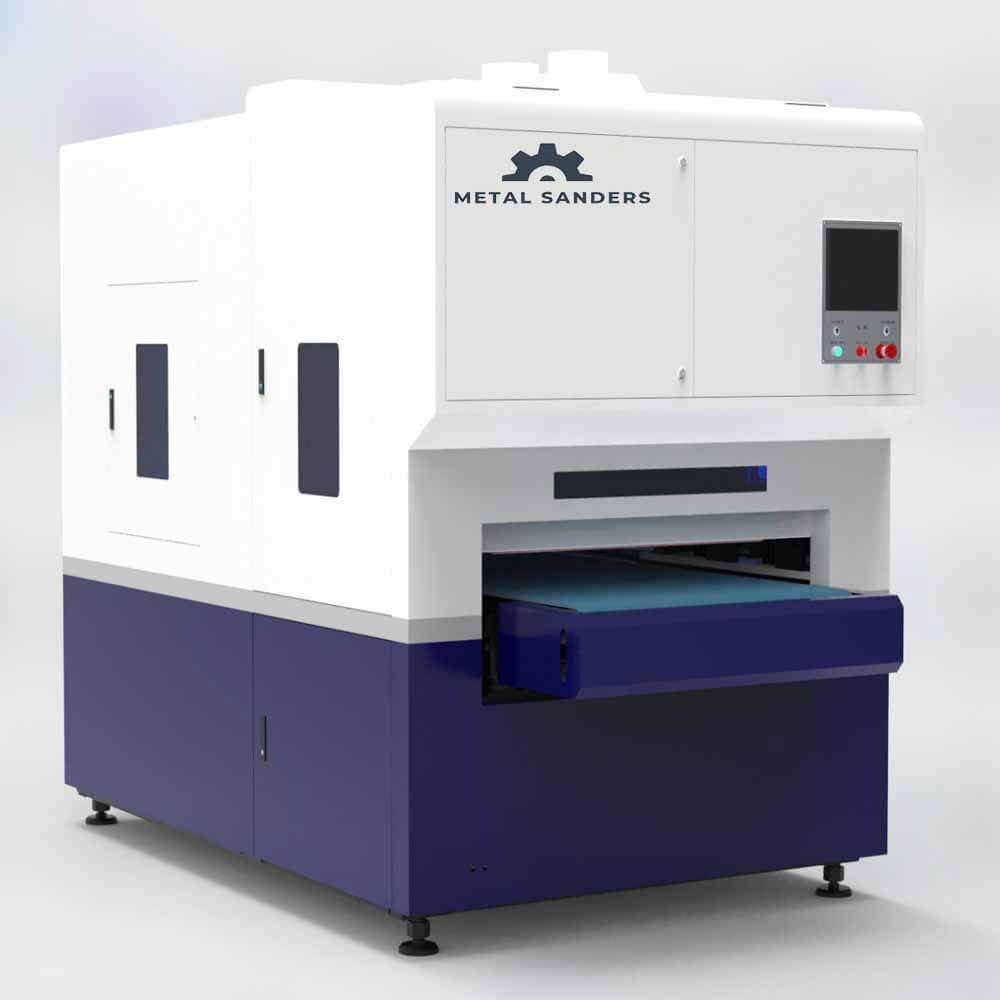

Automatic Stainless Steel Sanding Grinding Polishing Rotary Sheet Metal Polishing Deburring Machine

The Automatic Stainless Steel Sanding Grinding Polishing Rotary Sheet Metal Polishing Deburring Machine is an advanced solution designed to streamline these processes. This machine integrates cutting-edge technology to efficiently sand, grind, polish, and deburr metal surfaces, delivering superior results for industries such as automotive, aerospace, and manufacturing.

Table of Contents

What is a Sheet Metal Sanding Deburring Machine?

A Sheet Metal Sanding Deburring Machine is a specialized tool designed to remove burrs, sharp edges, and imperfections from metal sheets. By using abrasive sanding belts or discs, this machine smooths the surface of metals like stainless steel, ensuring a clean, polished finish. The deburring process eliminates rough edges left by cutting, laser processing, or stamping, enhancing the overall quality and safety of the metal parts.

The Sheet Metal Sanding Deburring Machine is essential for high-precision industries where the quality of the metal surface directly impacts the performance of the final product. By automating this process, manufacturers can significantly reduce manual labor and improve efficiency.

Key Features of the Polishing Machine Deburring Grinding Machine

The Polishing Machine Deburring Grinding Machine offers several key features that enhance its versatility and efficiency. The machine combines multiple stages of metal surface treatment—sanding, grinding, deburring, and polishing—into a single automated process.

Sanding and Grinding: The initial stage uses abrasive belts or discs to remove heavy burrs and rough surfaces. The grinding machine ensures that imperfections from cutting or shaping processes are smoothed out efficiently.

Polishing: After the sanding and grinding stages, the polishing machine uses specialized rollers or brushes to create a smooth, shiny finish on stainless steel and other metals. This stage is critical for industries that require aesthetically pleasing and smooth metal surfaces.

Rotary Technology: The rotary functionality of the machine allows for consistent and uniform processing of metal sheets. This ensures that the sanding, grinding, and polishing actions are applied evenly across the entire surface, producing high-quality results every time.

Automatic Operation: The automatic nature of the machine reduces manual intervention, allowing for continuous, high-volume processing. This boosts productivity while minimizing the potential for human error.

Benefits of the Automatic Deburring and Polishing Process

The Automatic Stainless Steel Sanding Grinding Polishing Rotary Sheet Metal Polishing Deburring Machine provides several advantages that are essential for modern metalworking processes:

Increased Efficiency: Automation allows for fast, consistent processing, reducing cycle times and increasing overall production rates.

Improved Surface Quality: The combination of sanding, grinding, and polishing ensures a flawless finish on stainless steel and other metal surfaces. This is crucial for industries where surface quality directly impacts product performance, such as in electronics, automotive parts, and medical equipment.

Cost-Effective: By automating the sanding, deburring, and polishing processes, this machine reduces the need for manual labor and minimizes material waste, leading to cost savings.

Versatility: Suitable for a wide range of materials, including stainless steel, aluminum, and carbon steel, the machine can be adapted to meet the needs of various industries and applications.

Reduced Operator Fatigue: The automated system reduces the physical strain on workers by eliminating the need for repetitive sanding and deburring tasks, promoting a safer working environment.

How the Polishing Machine Deburring Grinding Machine Works

The Polishing Machine Deburring Grinding Machine operates through a combination of abrasive sanding belts, grinding wheels, and polishing rollers. The process begins with the sanding stage, where abrasive belts remove heavy burrs and rough edges from the metal sheet. This is followed by grinding to refine the surface and remove any remaining imperfections.

In the final polishing stage, the machine uses specialized rollers or brushes to achieve a smooth, shiny finish. The rotary system ensures that all areas of the metal sheet are processed uniformly, delivering consistent results across the entire surface.

Conclusion

The Automatic Stainless Steel Sanding Grinding Polishing Rotary Sheet Metal Polishing Deburring Machine is an essential tool for industries that require high-quality metal surface finishing. By combining the functions of sanding, grinding, deburring, and polishing into a single automated system, this machine provides efficiency, precision, and consistency for stainless steel and other metal surfaces.

With its advanced features and automated operation, the Polishing Machine Deburring Grinding Machine ensures superior results while reducing labor costs and improving production efficiency. Whether used for deburring metal sheets, polishing stainless steel, or grinding metal surfaces, this machine is a reliable and cost-effective solution for modern metalworking operations.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: info@metalsanders.com

- Address: Wangtai Gongye Industry, Qingdao