Automatic Sheet Metal Polishing Deburring Machine for Cutting and Stamping Parts

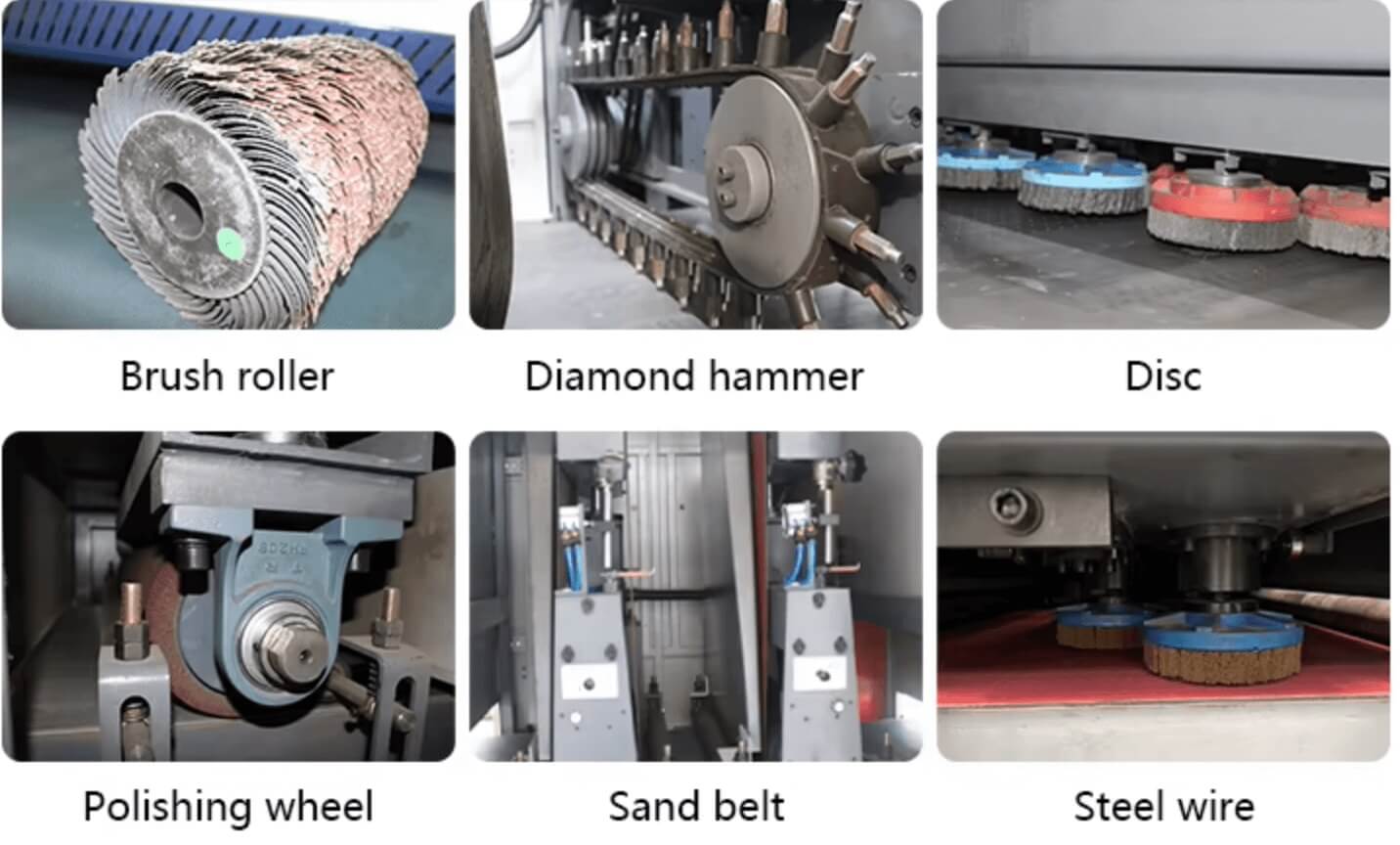

The Automatic Sheet Metal Polishing Deburring Machine is designed to meet this demand by efficiently removing burrs, smoothing edges, and polishing flat metal sheets. This machine integrates advanced wide belt sanding technology, making it an indispensable tool for metal fabrication workshops and factories.

Table of Contents

What Is an Automatic Sheet Metal Polishing Deburring Machine?

This automatic machine specializes in the deburring and polishing of sheet metal parts that come from cutting or stamping processes. It automates the feeding, sanding, grinding, and polishing steps on flat metal plates, improving efficiency and ensuring consistent surface quality.

Key features include:

Wide belt sanding for uniform material removal

Automated conveyor feeding for high productivity

Water cooling system for heat reduction and dust control

Suitable for stainless steel, aluminum, iron, and other metals

Advantages of the Wide Belt Sander Automatic Metal Sheet Polishing Machine

1. High Efficiency & Automation

Equipped with automatic feeding and pressure adjustment, this machine operates continuously with minimal manual intervention, ideal for large-scale production of flat metal plates.

2. Superior Surface Finish

With adjustable sanding belts and water grinding technology, it delivers smooth, scratch-free finishes that meet strict quality standards for automotive, appliance, and electronics industries.

3. Wide Processing Capacity

Supports sheet widths up to 1300 mm (and customizable), accommodating a variety of metal plate sizes used in different manufacturing sectors.

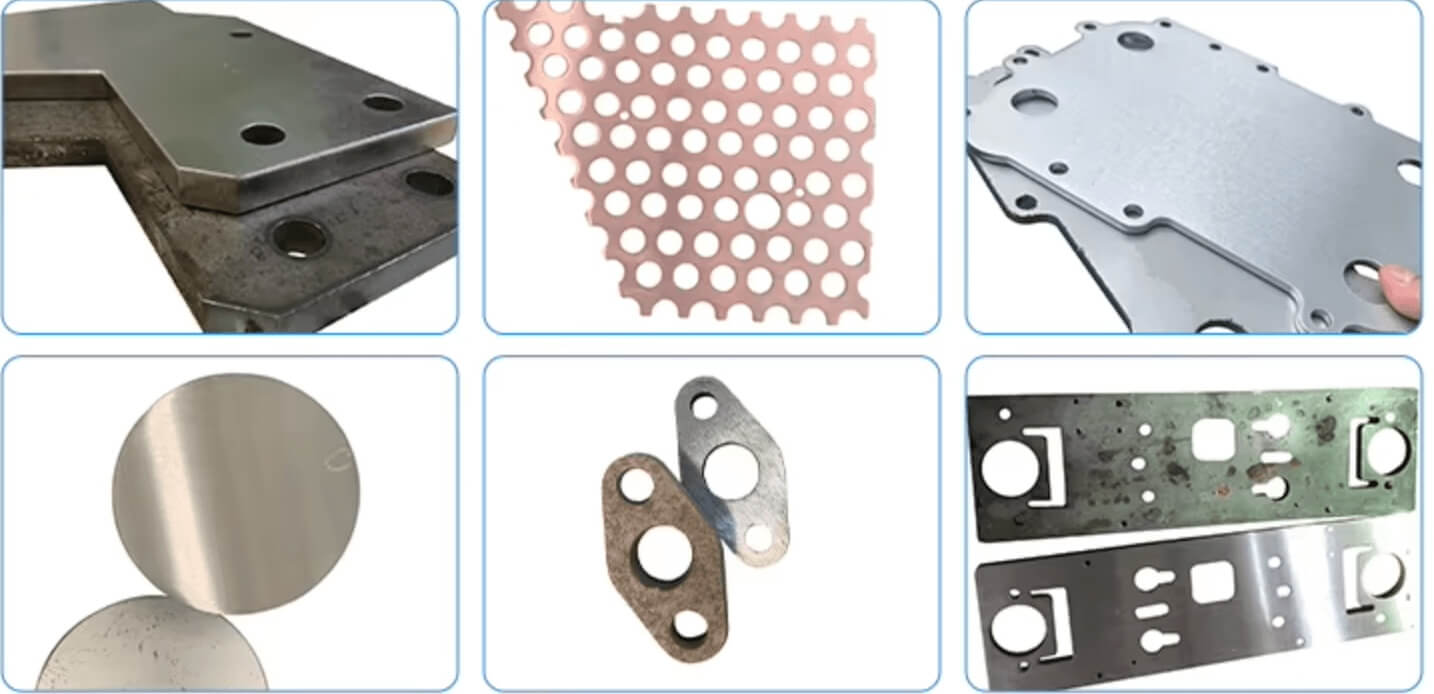

4. Durable and Versatile

Designed to work on multiple metal types including stainless steel, galvanized steel, aluminum, and iron sheets with thicknesses generally up to 10 mm.

5. Environmental & Worker Friendly

The integrated water grinding system reduces dust and heat generation, improving the working environment and extending abrasive life.

Recommended Applications

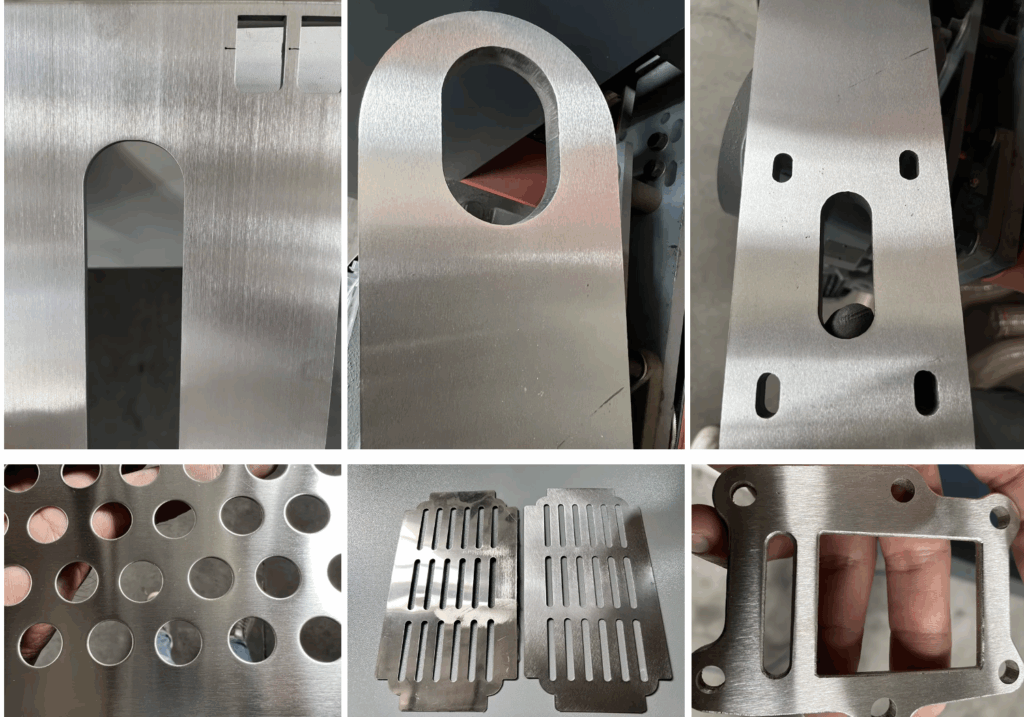

Deburring and polishing of stamped or laser-cut sheet metal parts

Surface preparation before painting or powder coating

Polishing of metal flat plates for kitchen appliances, elevator panels, automotive parts

Sanding and smoothing of aluminum and stainless steel sheets

Key Machine Parameters

| Parameter | Specification |

|---|---|

| Working Width | 1000-1300 mm (customizable) |

| Max Processing Thickness | Up to 10 mm |

| Belt Speed | 0-20 m/min (variable) |

| Motor Power | Main motor 7.5 kW |

| Feeding Method | Automatic conveyor feeding with pressure control |

| Abrasive Type | Wide sanding belts, flap wheels, polishing pads |

| Cooling System | Water cooling for grinding and dust control |

| Machine Dimensions (L×W×H) | Approx. 3500 × 1800 × 1600 mm |

| Power Supply | 380V/50Hz (customizable for export markets) |

| Control System | PLC touch screen control |

| Weight | Approx. 1500 kg |

Conclusion

The Automatic Sheet Metal Polishing Deburring Machine with wide belt sanding and water grinding technology is the ideal solution for efficient, high-quality surface finishing of cutting and stamping metal parts. It improves throughput, reduces manual labor, and guarantees uniform finishes, helping your production line stay competitive.

📞 Contact us now to get a personalized quote and expert advice on selecting the best machine for your metal sheet finishing needs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao