Automatic Polish & Deburring Machines for Metal Finishing

Let’s break down what these machines do, their core advantages, and how to choose the ideal system for your workshop or production facility.

Table of Contents

What Is a Cleaning and Deburring Machine?

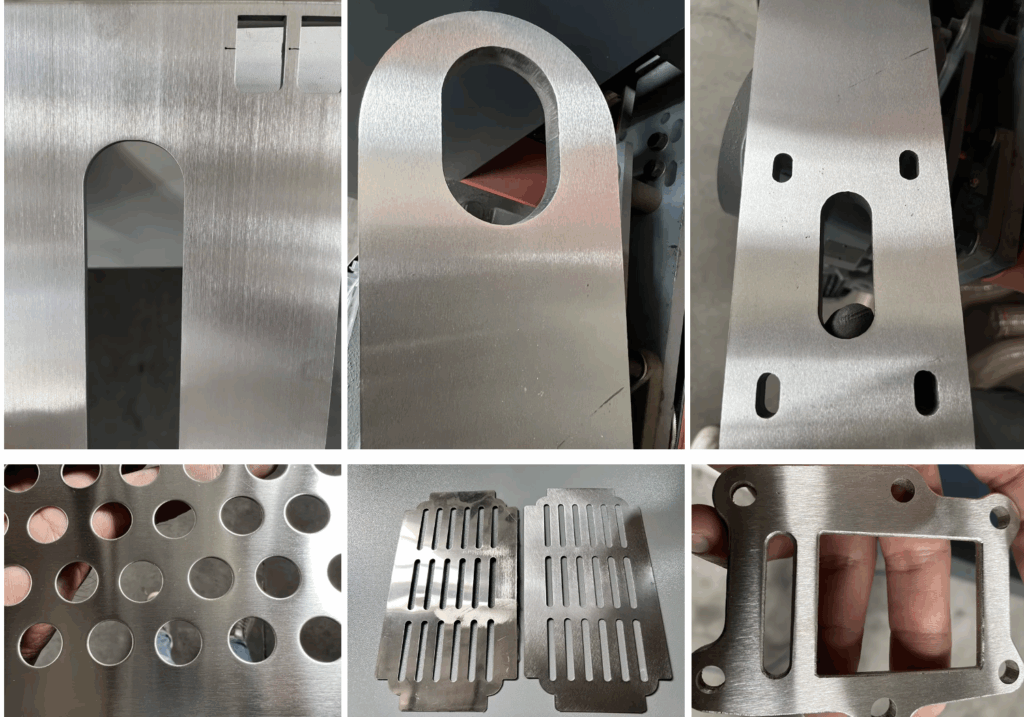

A Cleaning and Deburring Machine is a multifunctional surface processing unit designed to remove burrs, sharp edges, slag, and oxidation layers from laser-cut, plasma-cut, or punched metal parts. It improves surface smoothness and prepares components for further polishing, coating, or welding.

Key Features:

Removes sharp burrs and oxide film from cut edges

Suitable for a wide range of materials including stainless steel, carbon steel, aluminum, and copper

Enhances surface adhesion for coating, painting, or powder finishing

Available in dry or wet working modes

Industries Served: Sheet metal fabrication, kitchenware, automotive, electronics, and aerospace components.

What Is an Automatic Polish Sanding Machine?

An Automatic Polish Sanding Machine takes metal finishing to the next level. It uses programmed feeding and pressure control systems to polish and sand large quantities of parts without manual intervention, reducing labor costs while ensuring uniform results.

Top Benefits:

▶ Delivers consistent satin or mirror finishes

▶ Automates the polishing of flat metal sheets and welded components

▶ Suitable for stainless steel appliances, decorative panels, signage, elevator doors, and more

▶ Supports multiple working stations: sanding belt, scouring pad, polishing wheel, and buffing head

Why It Matters: Manual sanding is labor-intensive and inconsistent. Automation improves productivity, precision, and safety—especially for mass production.

Choosing the Right Abrasives for Deburring Machine

The effectiveness of any deburring or polishing process depends heavily on the quality of Abrasives for Deburring Machine. Different materials and finishes require specific types of abrasives to ensure optimal results.

Common Types of Abrasives:

Non-woven abrasive wheels: Ideal for oxide layer removal and satin finishes

Flap wheels: Used for edge rounding and general surface grinding

Abrasive belts: For wide-belt sanders to deliver even surface sanding

Scotch-brite rollers: Perfect for consistent surface blending and cleaning

Brush discs with ceramic or zirconia grain: For aggressive burr removal on harder metals

Machine Parameters: Cleaning and Deburring Machine & Automatic Polish Sanding Machine

| Parameter | Specification |

|---|---|

| Working Width | 1000 mm (standard model) |

| Max Processing Thickness | Up to 10 mm (depending on material) |

| Working Speed | 0-20 m/min (adjustable) |

| Motor Power | 7.5 kW main motor |

| Abrasive Types Supported | Sanding belts, flap wheels, non-woven wheels, brushes |

| Feeding Method | Automatic conveyor feeding with adjustable pressure |

| Dust Collection | Integrated dust extraction system |

| Machine Dimensions (L×W×H) | Approx. 3000 × 1500 × 1600 mm |

| Power Supply | 380V/50Hz (customizable for different regions) |

| Control System | PLC with touchscreen interface |

| Wet/Dry Operation | Supports both wet and dry finishing modes |

| Weight | Approx. 1200 kg |

Conclusion

Achieving perfect edges and finishes is no longer optional—it’s the standard. With a modern Cleaning and Deburring Machine, a reliable Automatic Polish Sanding Machine, and the right Abrasives for Deburring Machine, you gain a competitive edge in product quality, labor efficiency, and workflow automation.

Contact us today to request a quote or get expert advice on optimizing your metal surface finishing line. Whether you’re upgrading a workshop or automating an industrial plant, we’ll help you find the perfect solution.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: info@metalsanders.com

- Address: Wangtai Gongye Industry, Qingdao